Linear Vibrating Screen

Introduction

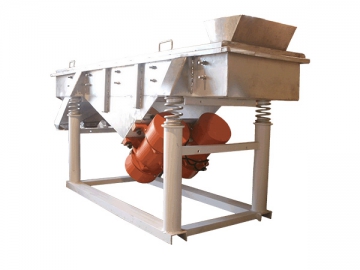

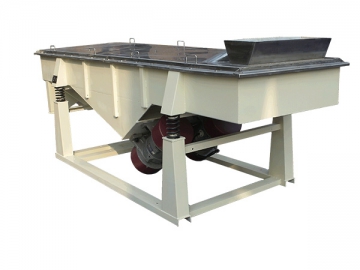

Our linear vibrating screen is a kind of small and medium size multi-layer screening machinery. Its performance has reached the international advanced level. Any dry material with a diameter of 0.074mm-15mm can be handled. The maximum granule diameter should be less than 20mm. As a multi-layer screen, this machine could come with seven layers of screen at most.

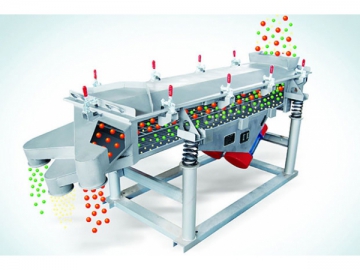

Principle

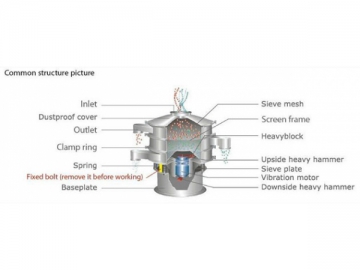

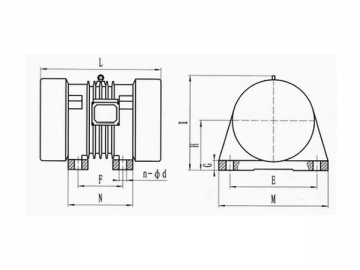

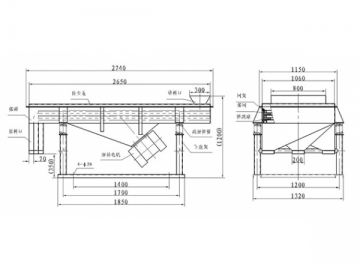

The linear vibrating screen is composed of screen box, screen frame, vibration motor, shock absorber and machine base. The two same vibration motors, as the vibration providers, are fixed on the top of screen box. They rotate synchronically in reverse directions.

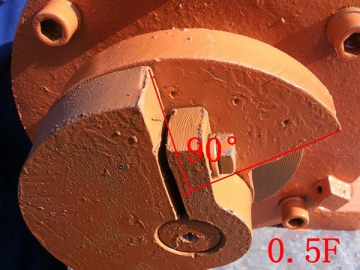

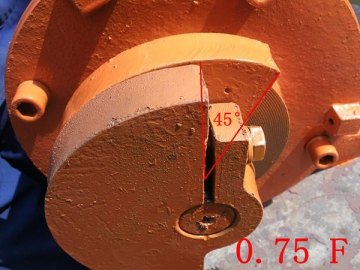

The eccentric blocks driven by the motors could provide centrifugal force, whose component force moves back and forth along the casting direction. Thus the screening device supported by the shock absorbers can move linearly, and the material on it moves forward straightly when tossed upward. When falls into the screen frame again, the material will move forward quickly and penetrate the screen in a fluffy state. Desirable screening performance can be achieved simply by choosing suitable screens for the linear vibrating screen.

Feature

1. The screening precision is great, while the blocking rate of the screen is less than 10% in average.

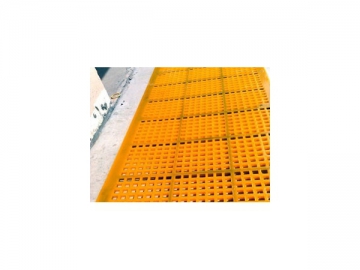

2. The screen frame is usually made of wood. If the mesh diameter is larger than 2mm and the production capacity is high, the stainless steel frame could be used.

3. Enclosed structure is adopted for the linear vibrating screen to avoid particulate matter pollution to the air.

4. The low energy consumption and low noise (73~80dB) make the machine quite eco-friendly.

5. The screen is woven by stainless steel wire, so its service life is quite long and the maintenance is simple. It can be used in single layer or multi-layer (7 layers at most).

6. The motor can be mounted either at the bottom or on the side of the vibrating room.

Application

1. Food industry

This linear vibrating screen can be used for handling starch powder, sugar powder, salt, rice flour, milk powder, soy bean milk, sauce, fruit juice, condiment, and so on.

2. Chemical industry

Our high efficiency screener is widely used for processing resin powder, paint, industrial chemicals, detergent powder, cosmetic, Chinese medicine powder.

3. Metallurgy industry

In metal processing industry, this linear vibrating screen can sift alluminium powder, lead powder, copper powder, alloy metal powder, electrode powder, manganese dioxide powder, electrolytic copper powder, abrasive powder, high temperature resistant material, Kaolin, limestone, dolomite, alumina, calcium carbonate, quartz sand, and so on.

4. Pollution abatement

Our linear vibrating screen is also suitable for treating waste oil, sewage, accessory ingredient, activated carbon

Parameter

Parameter| Model | Screening area (mm) | Layer | Mesh size (mm) | Capacity (t/h) | Rotary speed (rpm) | Double amplitude (mm) | Power (kw) | Dimension (mm) |

| 500× 2000 | 1 | 2-200 | 0.05-5 | 960 | 6-7 | 2×0.4 | 2140×808×848 | |

| 2 | 0.05-5 | 960 | 6-7 | 2×0.4 | 2199×808×878 | |||

| 3 | 0.03-5 | 960 | 4-6 | 2×0.4 | 2256×808×938 | |||

| 500× 2500 | 1 | 0.06-8 | 960 | 5-7 | 2×0.4 | 2642×808×848 | ||

| 2 | 0.06-8 | 960 | 4-6 | 2×0.4 | 2699×808×878 | |||

| 3 | 0.06-8 | 960 | 6-8 | 2×0.75 | 2750×808×938 | |||

| 4 | 0.1-15 | 960 | 5-7 | 2×0.4 | 2813×808×1000 | |||

| 5 | 0.08-15 | 960 | 5-7 | 2×0.4 | 2883×808×1060 | |||

| 6 | 0.07-15 | 960 | 6-8 | 2×0.75 | 2953×808×1120 | |||

| 1000× 2000 | 1 | 0.12-20 | 960 | 6-8 | 2×0.75 | 2152×1320×900 | ||

| 2 | 0.11-20 | 960 | 5-7 | 2×0.75 | 2219×1320×960 | |||

| 3 | 2-200 | 0.10-2 | 960 | 5-7 | 2×0.75 | 2286×1320×1030 | ||

| 4 | 0.07-15 | 960 | 4-8 | 2×0.75 | 2353×1320×1100 | |||

| 5 | 0.07-15 | 960 | 4-8 | 2×1.5 | 2420×1320×1160 | |||

| 6 | 0.07-15 | 960 | 4-8 | 2×1.5 | 2487×1320×1220 | |||

| 1000× 2500 | 1 | 0.1-15 | 960 | 5-7 | 2×0.4 | 2203×1320×900 | ||

| 2 | 0.08-15 | 960 | 5-7 | 2×0.4 | 2269×1320×960 | |||

| 3 | 0.07-15 | 960 | 6-8 | 2×0.75 | 2336×1320×1030 | |||

| 800× 3000 | 1 | 0.1-20 | 960 | 6-8 | 2×0.75 | 3080×1098×1120 | ||

| 2 | 0.1-20 | 960 | 6-8 | 2×0.75 | 3140×1098×1180 | |||

| 3 | 0.1-20 | 960 | 6-8 | 2×1.5 | 3200×1098×1240 | |||

| 1000× 3000 | 1 | 0.1-20 | 0.1-20 | 960 | 6-8 | 2×0.75 | 3152×1340×1120 | |

| 2 | 0.1-20 | 960 | 6-8 | 2×1.5 | 3219×1340×1120 | |||

| 3 | 0.1-20 | 960 | 6-8 | 2×1.5 | 3286×1340×1120 | |||

| 1200× 2400 | 1 | 0.1-23 | 0.1-23 | 960 | 6-8 | 2×0.75 | 2480×1520×1100 | |

| 2 | 0.1-23 | 960 | 6-8 | 2×0.75 | 2540×1520×1160 | |||

| 3 | 0.1-23 | 960 | 6-8 | 2×1.5 | 2600×1520×1220 |

Product detail

1. Simulating diagram for screening

- Stainless steel

- Carbon steel

- Stainless steel (contacting with

material)

Optional configuration and service

1. The linear vibrating screen could be modified to suit various power voltages, including 110V, 220V, 240V, 380V, 415V, 450V and 550V, different power frequencies, 50Hz and 60Hz, and even single phase electricity.

2. The wheel, viewing hole, and frequency converter are available according to your requirements.

3. The OEM service is available for our linear vibrating screen.