Ultrasonic Vibrating Screen

Introduction

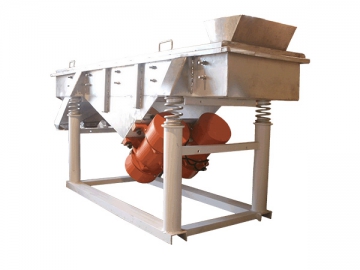

Our ultrasonic vibrating screen is a high precision fine powder screening machine. It has low working noise and high screening efficiency. The machine is entirely enclosed. It only takes 3-5 min to change the sieve. This device can also serve as an premium granule sifting machine, and serous material screening machine.

Principle

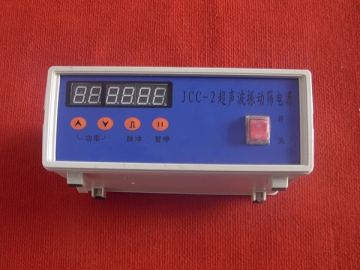

The ultrasonic vibrating screen can convert 220V/50Hz and 110V/60Hz power into 18KHz power. The ultrasonic transducer can transform this high frequency power into mechanical vibration of the same frequency. The suitable fine powdery materials include those with a diameter of 0.063-0.02mm.

This powder screening system, based on the traditional circular vibrating screen, comes with a low amplitude and high frequency ultrasonic vibration wave on the screen during the operation. Thus the fine powder can gain large ultrasonic acceleration, reducing its adhesion, friction, and wedging in the meshes. Then our ultrasonic vibrating screen can achieve high efficiency screening and screen cleaning.

Feature

1. During the gravity setting, low density powder ( < 0.3 tonnes per cubic meter) can be prevented from slightly contacting with the meshes to some degree, and the material mobility can also be reduced. Besides, the high density metal powder can be prevented from staying at or wedging into the meshes, and the material’s adhesion to the mesh due to the static charge can be alleviated. Thus the screening performance and efficiency can be both improved.

2. The penetrating rate of the material is generally 50%-400% higher than that of vibrating screen without ultrasonic transducers.

3. The screen cleaning time for our ultrasonic vibrating screen is greatly reduced, and sometimes this procedure can be saved.

4. The accessories like the bouncing balls won’t produce any contamination to the powdery material.

5. The mesh size and screening precision are stable.

6. Those materials adhering to the screen can be decomposed, reducing the materials left on the screen.

7. The screening times can be greatly reduced.

8. A self-protective motor is available for the ultrasonic vibrating screen. When there is a short circuit, phase loss, or unstable voltage, the motor will stop working automatically. Thus both the motor and the power supplier can be protected, making the operation much safer.

9. The motor has an IP rating of IP65. It is heat resistant, oil resistant, dustproof, and waterproof.

Product detail

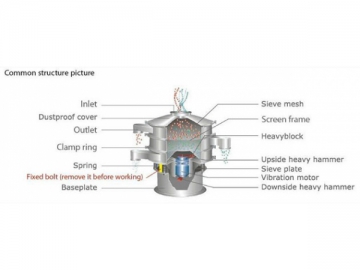

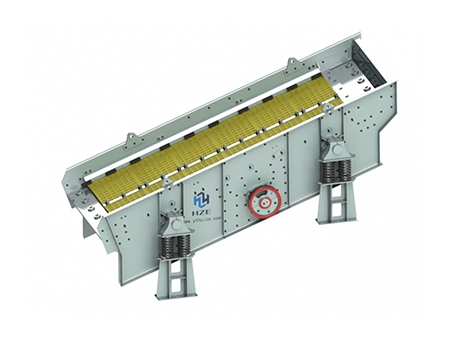

1. Product picture- Vibration motor

- Ultrasonic transducer

- Ultrasonic cabinet

- Ultrasonic screen frame

- Screen stretching rings

- Silicone sealing element

- Sieve

- Fastening ring

- Screen compartment

Optional configuration and service

1. A wide range of voltages, including 110V, 220V, 240V, 380V, 415V, 450V and 550V are supported according to your needs.

2. Both 50Hz and 60Hz power can be used.

3. You can choose wheel, viewing hole and frequency converter for our ultrasonic vibrating screen as you want.

4. The OEM service is available.