Multilayer PCB

The multilayer PCB fabrication is commenced at interior layer. Single sided or double sided substrate is produced by etching, and then these individual boards are deployed to specified layers. After heat treatment, pressing treatment and bonding treatment, multilayer board is eventually finished. As for hole drilling afterwards, same method as double sided PCB hole drilling is applied.

Advantage

The multilayer PCB is distinguished by prominent circuit density, small size and light weight. Thanks to exceptional circuit density, every single module and component require minimized connecting, whereupon drastically enhancing PCB stability and performance. Moreover, variable wiring layers swells PCB design flexibility.

Classification

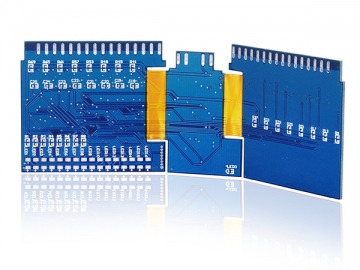

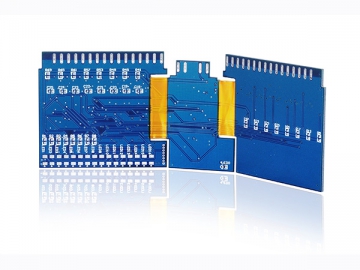

1. Four Layer Rigid-Flex Board

Rigid-flex circuit board is the blend of 3 rigid boards and 2 flex boards. Rigid board is four layer PCB, and flex board is single sided PCB. Various functions are laminated into one small unit, thus delivering easy installation. This PCB design and manufacture are conducted with the aid of X and Y axis for ensured circuit precision. This kind of multilayer PCB is ruggedly design for engineering control devices.

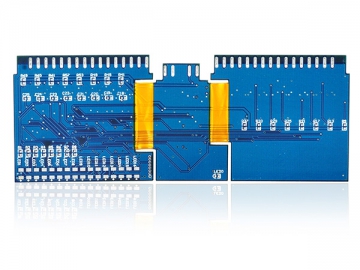

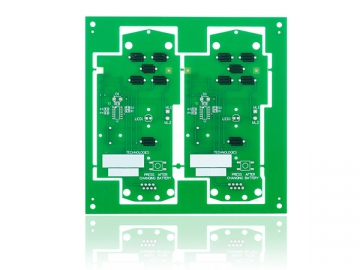

2. Four Layer Card

Featuring 0.3mm BGA and gold fingers, this product receives soldering and gold plating treatment. When soldering, we utilize blue solder mask to protect gold fingers. This product is well-suited for memory bank and network card.

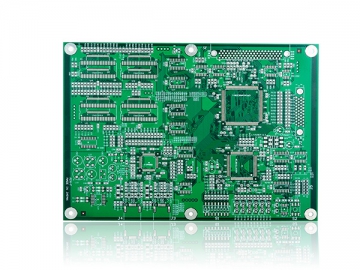

3. Six Layer ENIG PCB

0.2mm vias are covered with solder mask. Trace width reaches 0.1mm. Therefore, this multilayer PCB is regarded as high precision circuit board, which is often used for air conditioner PCBs.

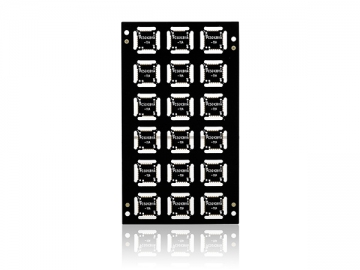

4. Eight Layer HASL PCB

This PCB features dark green solder-mask, and comes in 2.0mm thickness. It has been extensively applied to be main control board and electronic products.