MD Series Dredging Pump

Features

1. Available with only one impeller, the MD series dredging pump sucks up slurries containing sand and silt from one suction side. It is in essential a horizontal cantilever slurry pump.

2. The single-casing pump comes with a discharge outlet that ranges from 300mm to 500mm in diameter, while the double-casing model has a discharge outlet with diameter somewhere between 600mm and 1000mm.

3. Options of shaft seal: packing seal, mechanical seal, a combination of the first two (for single-casing models), and helix L rubber seal (for double-casing pumps).

Advantages

1. The physical layout of this dredging pump allows easy installation and use on the dredger. Simplified structure also delivers reliability.

2. For dredging pumps with large-diameter discharge outlets, we utilize a double-casing design that allows the internal liners to be completely worn out before replacement is needed. This design also prevents water from entering even when the liners are broken.

3. Front disassembly allows easy repair and maintenance.

4. The impeller is threaded onto the pump shaft via the 4-starts acme screw thread. This way of joint allows not only transmission of large torque but also easy installation and disassembly. The sleeve O-ring makes it easy for users to dismantle the impeller from the shaft.

Hydraulic Modeling

1. A steep-curve pump is desirable for pumping sediments to a wide range of distances. The pump curve describes the relation between flow rate and head.

2. Advanced hydraulic model minimizes head loss, further ensuring high efficiency and low power consumption.

3. Reliable shaft seal allows the pump to be 100% leak-proof.

4. Optimal cavitation performance gives the single-suction dredging pump a great ability to draw up sediments from a deeper depth with higher solids concentration.

5. Specially designed vanes create wide flow passages which allow the dredger to scoop up gravel, sand, or high-plasticity clays continuously without causing clogging.

6. Wet-end parts are made from alloy cast iron of high wear resistance, which ensures the best service life possible.

Applications

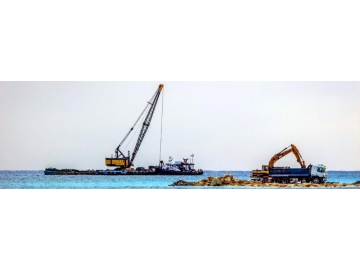

Scooping up mud, drawing up sand, and hydraulic filling.

Parameters

Technical Parameters

Size: 200-1000mm

Flow rate: 450-27500m3/h

Total head: 10-75m

Components

| Parts | Materials | Materials Code | Description | Hardness | Performance | Applications |

| Wet-end partsStuffing Box (Packing Gland) | Metal | M05 | 27% high-chrome cast iron | HRC≥58 | Erosion resistance is marginally lower than M07 and has corrosion resistance. | Used for high wear applications with a slurry pH between 5 and 12. |

| M07 | 15% high-chrome cast iron | HRC≥59 | Erosion resistance and wear resistance higher than M05 | For high impact and wear applications | ||

| M12 | 30% high-chrome cast iron | HRC≥65 | Wear resistance better than the first two materials | Used for high abrasion applications | ||

| Dredging Pump Base Bearing Assembly | Metal | Ductile cast iron | ||||

| Shaft | Metal | 1045 | Case hardening |