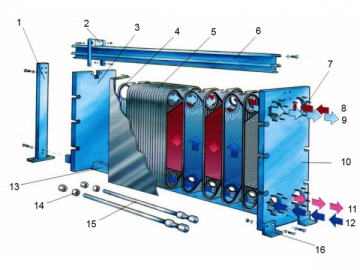

Plate Heat Exchanger

JPVF's plate heat exchanger consists of a pack of corrugated metal plates that is assembled between the fixed frame plate and a movable pressure plate. Rectangular channels are formed between two adjacent plates. Heat is transferred through the plate between two channels.

The plate heat exchanger is often considered an ideal piece of heat transfer equipment where heat exchange occurs between two liquids, or gas and liquid. It delivers a heat transfer coefficient 3 to 5 times that of a shell and tube heat exchanger with the equivalent pressure drop, while it takes only one third as much space as the shell and tube unit. A high heat recovery rate of up to 90% makes our plate heat exchanger a popular choice for heating, cooling, evaporation, condensation, disinfection, and waste heat recovery applications in metalliferous mining, petroleum, chemical engineering, electric power plants, pharmaceutics, food, chemical fiber, shipping, and heat supply industries.

Plenty of choices are available to meet you specific applications requirements. The metal plates can be either bolted or brazed together. From there, the equipment gets its name, bolted plate heat exchanger and brazed plate heat exchanger. A variety of plate surface patterns are among options, including corrugated, chevron-type, and dimpled plate. For more information, please contact us!

Benefits

1. High Efficiency

The plate heat transfer equipment has a heat transfer coefficient somewhere between 3000 kcal/m2·℃ ·h and 4500 kcal/m2·℃ ·h.

2. Compact Structure

Plates are compressed tightly together. Compared with other heat transfer equipment, the plate configuration has a smaller footprint and takes up less space. With the equivalent heat transfer rate, the plate heat transfer equipment takes only 1/5 as much space as the shell and tube unit.

3. Easy Cleaning, Disassembly, and Assembly

The plate pack is tightly clamped between the frame plate and movable pressure plate by bolts. It is easy to take the set-up apart for cleaning and inspection. Smooth plate surface creates ideal channel which promotes turbulence and makes is unlikely to cause water deposits.

4. Long Service Life

Stainless steel or titanium alloy is selected to make the plate for maximum resistance to corrosive media. Gaskets are easily replaced and allow easy maintenance.

5. Flexibility

Increase and reduction of the heat transfer area is a rather straightforward process in a plate heat-exchanger, through the addition or removal of plates from the stack.

6. Media Mixing Prevention

Discharge channels are available which ensure different media do not mix. When leakage does occur, the medium flow would be discharged outside the plate.

7. Versatility

The equipment can be used in the heater, condenser, and cooler.

1. Rear Support Column, 2. Roller Assembly, 3. Removable pressure plate, 4. Gasket, 5. Plate pack, 6. Guiding bar, 7. Stud bolt, 8. Hot in, 9. Cold out, 10. Fixed frame plate, 11. Hot out, 12. Cold in, 13. Lower guiding bar, 14. Tightening nut, 15. Tightening bolt, 16. Frame foot