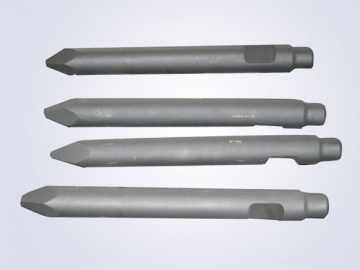

Chisel Pin

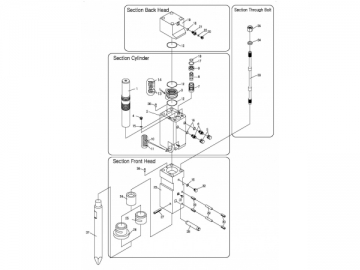

The chisel pin is an important part of the hydraulic breaker which can be attached to the excavator and road roller at the construction site.

Don't be fooled by the number of names used to refer to this construction machinery part. Names for this hydraulic breaker chisel pin may vary from country to country, including the retainer bar, tool pin and hydraulic hammer chisel retainer which are popularly used in Europe, Asia, and North America. But they mean the same thing and work the same way. A chisel pin or, tool pin, is inserted through the tool pin hole of a hydraulic breaker to hold the breaker chisel (or simply, tool) in place and prevent it from coming off.

CHIXIN's experience is unrivalled in the construction or demolition equipment industry as the company is among the earliest Chinese manufacturers of hydraulic breaker cylinders, chisels, and retainer bars. At CHIXIN, we understand that high quality and high precision is a universal need regardless of time or location. That is why we maintain tight control of quality throughout every step of production. Below are a few quality control aspects that we believe have made a difference.

Raw Material Selection

We bear two things in mind when selecting raw materials. One is to select the right raw material. The other is to budget on transportation cost. After factoring in quality and cost, we decide to pick from a nearby supplier 40Cr as the making material for its great mechanical strength, hardenability, and ductility. Getting a supplier who is close to us saves money on transportation cost as raw materials are delivered to our job site within only 50 minutes.

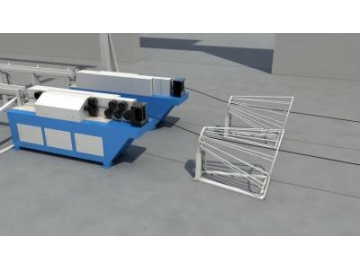

Manufacturing

Heat treating is crucial for building a robust hydraulic machinery part. That is why we have enforced very strict hardening procedures. Each retainer bar is hammered out through a process known as forging, contrary to the popular drawing process which produces shoddy bars that yield easily to pressure, wear, and abrasion. The combined efforts of heat treating and hardening produce quality chisel pins that last longer. If it lasts longer, the cost is less.

A staff of senior engineers and technical experts work closely with our craftsmen to get their production tasks done right, with high expertise. Our state of the art equipment allows all the manufacturing processes to be done in-house, including lathing, planing, milling, drilling, boring, and grinding.

Precision Control

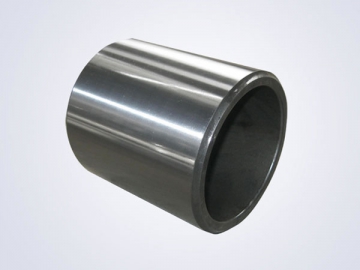

We work day and night to monitor dimensions, hardness, and geometry of the spare parts. The finished tool pin for breakers falls within the tolerance band of 0.2mm-0.5mm for each dimension specified. High precision parts ensure a tight fit in the hydraulic breaker cylinder. If there is too much clearance between the retainer bar and cylinder bore, the retainer bar will end up moving side to side, creating a loud slapping sound. Severe bar slap would cause cylinder breakage.

Customization

The hydraulic breaker cylinder varies by model. That is why every retainer bar needs to be customized to suit the specific kind of cylinder. Simply throw us a technical drawing and we can tailor make the right chisel pin accordingly in the shortest possible time.

Presently available are two types of chisel pins: the tool pin with holes and the tool pin without holes.