SMART Series Small Size Variable Frequency Drive

To satisfy requirements from industrial automation industries, our company has launched the next-generation variable frequency drive, namely the SMART series VFD. The state of the art VFD houses inside optimized hardware and software while offering 2 control modes: the scalar V/F control and vector control. Excellent drive performance comes from high reliability, adjustability, and integrated controls. Typical applications for this small-sized variable frequency drive are in the food packaging, textile, and machinery industries.

We at Easydrive Electric understand that different industries may require varied power control functionalities. That is why we have offer OEM and ODM services which allow your desired variable frequency drive customized here. Simply tell us your VFD specifications, and we can provide an integrated solution just for you.

Features of Variable Frequency Drive

1. Power input terminals

With the input lead on top and the output lead on bottom, the wiring of this VFD is pretty simple. Flame-retardant, reinforced ABS is selected to make the VFD body.

2. Powerful Functions

Built PID, simplified PLC system, and 8 preset speeds. Integrated Modbus485 serial bus, double control modes (vector control and scalar V/F control), and built-in braking circuit.

3. Remote Control Port

The remote control port supports standard RS-485 communications. It comes with an extend cable which allows the keyboard to be connected to the port at a distance. 8-pin network cable provides easy access to the internet.

4. Unique Structure

The air flue is separated from the drive control module. The capacitor is mounted onto the air channel but is insulated from it. The IPM, or intelligent power module for short, provides an easy way to cool the VFD components.

5. Multifunction Keypad

Turn the knob of the keypad clockwise to increase the inverter drive's frequency. The keypad comes with an LED display, and supports remote network control. Frequency control accuracy: 0.01Hz

6. Overall Reliability

The variable frequency drive is certified by the EMC testing lab. It has been also approved in the electrical inspection conducted by China National Center for Quality Supervision and Test of Electrical Control and Distribution Equipment.

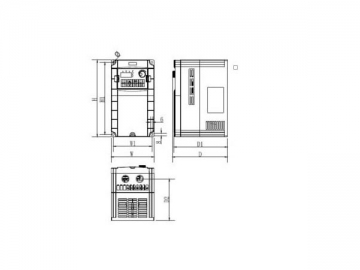

VFD Installation Size

0.7KW-2.2KW

0.7KW-2.2KW  3KW-4KW

3KW-4KW

| Specification | W | W1 | H | H1 | H2 | D | D1 | D2 | D3 | Diameter of mounting hole | Diagram |

| 100 | 89 | 151 | 140 | 140 | 135 | 101.5 | 91 | Φ5 | (a) | ||

| 120 | 108 | 215 | 202 | 154 | 150 | 116 | Φ5.5 | (b) | |||

| Item | Standard Specs | |

| Input | Rated voltage and frequency | Single-phase 220V, 3-phase 380V, 50Hz |

| Allowable variations (tolerance) | Voltage: -20%~ 20% Voltage unbalance rate: <3% Frequency: ±5% | |

| Output | Rated voltage | 0~220V/0~380V |

| Frequency range | 0Hz~2000Hz | |

| Overload capacity | 150% overload for 1 minute, 180% overload for 1 second, 200% (immediate protection measures required) | |

| Major control functions | Modulation mode | PWM (abbreviated for pulse width modulation, which uses voltage vector for effective conotrol ) |

| Control mode | Vector control Scalar V/F control | |

| Frequency accuracy | Digital mode: max. frequency ×±0.01% Analog mode: max. frequency ×±0.2% | |

| Frequency resolution | Digital mode: 0.1Hz Analog mode: max. frequency×0.1% | |

| Starting frequency | 0.0Hz~10.00Hz | |

| Torque rise | Automatic torque rise Manual torque rise: 1%~30.0% (only effective in V/F control mode) | |

| V/F curve | Linear V/F curve Quadratic V/F curve User-defined V/F curve | |

| S-curve acceleration and deceleration | Optional time units: minute/second Max. time: 3600S (0.1~3600s) | |

| DC braking unit | Operating frequency: 0-online frequency Braking time: 0~30s | |

| Carrier frequency | 1.0K~12KHZ | |

| Jog | Jog frequency range: 0.1Hz~50.00Hz , Jog acceleration/deceleration time: 0.1~3600s | |

| Built-in PID Controller | A closed loop control system is formed with the aid of PID, applicable for process control, like flow rate and pressure adjustment. | |

| Multiple preset speeds | The PID system, together with control terminals, enables a number of operating speeds | |

| Automatic voltage regulation | When the mains voltage changes, the output voltage is kept constant by adjusting PWM output (AVR function). | |

| Power saving mode | V/F curve is optimized automatically to changing electric loads in an attempt to achieve maximum running efficiency. | |

| Automatic current control | Current-limiting features prevent the VFD control tripping on a fault caused by excess current. | |

| Senseless vector control | Torque | 200% torque output at 1.5Hz |

| Automatic display of motor parameters | Operators can get motor status data from the display screen when the variable frequency drive stops operating. | |

| Item | Standard specifications | |

| Run Enable | Command channels | Control Board Control Terminal Serial Communication Port |

| Frequency adjustment | Analog potentiometer ▲ and ▼ command buttons Functional code UP/DOWN terminals Analog voltage Analog current Pulse | |

| Discrete input | 7 programmable discrete inputs with max. 30 functions to set | |

| Analog input | AI1, AI2 0~10V/0~20mA | |

| Analog output | 1-way analog signal output Power supply: 0/4~20mA, 0/2~10V Output physical quantities: frequency | |

| Discrete Output | 1-way programmable open collector output 1-way relay output signal Multiple physical outputs | |

| Operation panel | LED digital display | To display frequency, output voltage, output current and other parameters. |

| Peripherals | Physical displays of output frequency, output current and output voltage, etc. | |

| Protective function | Over-current protection Over-voltage protection Under-voltage protection Overheat protection Phase loss protection overload protection, etc. | |

| Options | Brake assembly Remote control Extension cable Keyboard support | |

| Operating Conditions | Applicable areas | Designed mainly for indoor applications where the adjustable speed drive should be protected from direct sunlight, dust, corrosive gas, oil mist and water steam, etc. |

| Altitude | <1000m (Your variable frequency drive may experience performance degradation when the altitude exceeds 1000m.) | |

| Ambient temperature | - 10°C~+ 40°C | |

| Humidity | < 90%RH (no condensation) | |

| Vibration | < 5.9m/s2 | |

| Storage temperature | -20°C ~+ 60°C | |

| Structure | Protection grade | IP20 |

| Cooling method | Forced air cooling | |

| Installation method | Wall-mounted in cabinet | |

Application of Variable Frequency Drive

The SMART series variable frequency drive is designed mainly to adjustmotor speeds in light-duty machinery and to meet industrial automation requirements. Typical usesof variable frequency drive are in the work carving industry, circular knittingmachine, food packaging machinery, textile equipment, wire stripping machine, blanking machine, fan, and material feeder.