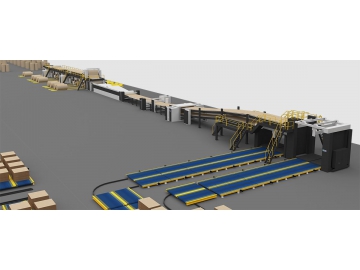

5 Ply Corrugated Cardboard Production Line

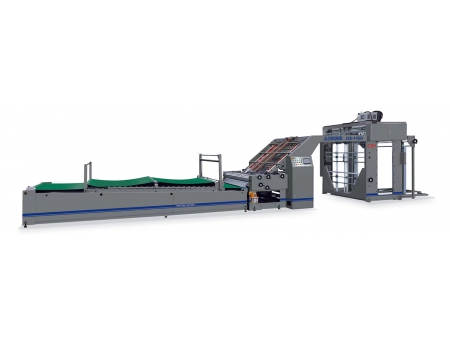

Similar to the 3-ply type, our 5 ply corrugated cardboard production line also features centralized control. So, it can be easily operated and maintained. Concurrently, high efficiency and safety can be ensured. With this corrugated board making plant, automatic production of cardboard in large volumes can be readily completed, thus ensuring significant reduction of labor intensity.

Thanks to the high temperature heat transfer oil that is used as heat source of the whole corrugated paperboard machine, over 60% energy can be saved when compared with stream heating. Therefore, energy consumption can be greatly reduced and large production cost can be effectively cut down. Owing to this, our 5 ply corrugated cardboard production line is an economical machinery suitable for medium and large scale carton plants.

Components and Characteristics

1. No-shaft roll stand: Two arms can rise and fall separately.

2. Paper mounting machine: Electromagnetic speed regulating motor is used.

3. Double deck glue machine:

4. Dryer: It consists of 14 heating plates. The total length is 10 meters. Due to pneumatic expanding device, the conveyor belt can be separated automatically when power's off.

5. Forming part: The forming part is composed of 27 pairs of forming rollers.

6. Slitter scorer: It is available in ultra thin blade type and general blade type. High automation and simple operation is ensured.

7. Cut-off knife: NC single knife and double knife as well as mechanical single knife and double knife are available.

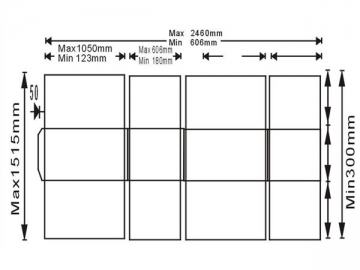

Specifications of 5 Ply Corrugated Cardboard Production Line

Models: 1300type, 1450type, 1600type and 1800type

Total length: 68m

Total power: 150kw