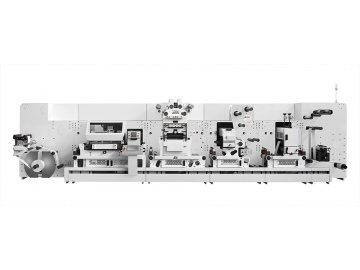

High Speed Automatic Printer Slotter and Die Cutter

Introduction

The high speed automatic printer slotter and die cutter is specially designed for unique corrugated cardboard converting. It combines robust construction with user friendly features to achieve remarkable quality. This high speed automatic flexo printing slotting and die cutting machine is controlled by PLC program. Frequency converter is used to adjust control phase. Touch screen and button form dual operation system.

Other functions are also valuable such as controllable ink roller which can rise and fall intelligently, forme auto zero set after being cleaned, operator friendly position aligning, automatic standby after the norm is accomplished, etc.

Unit Features

1. The main drive gear is made of premium alloy steel (20CrMnTi). After experiencing carburizing and quenching as well as abrasive machining, it enjoys high hardness (HRC58-62) and high precision (sixth level precision).

2. The touch screen can display set number, controlling position adjustment of each group of printing roll and die cutter. In addition, you can set production speed through the touch screen and clearly see counted number and prompt message on it.

3. The paper pull roll boasts self-locking and quick adjustment functions, avoiding roll shaft damage resulted from traditional fastening by screw and extreme inconvenience on operation.

4. Key-free connector is employed so that the gap caused by conventional connecting can be eliminated, maintaining long lasting precision of printing colors.

5. The lubricating system comes with spray type splash-proof unit. The system can circulate automatically and is provided with anti-leakage unit.

6. Air cylinder locking between units and self-locking mechanism of the whole machine ensures high stability.

Feeding Unit

Features of Feeding Unit

1. The feeding unit of our automatic printer slotter and die cutter applies negative pressure vacuum suction feeding system to assist feeding of special paper. Skip feeding is possible for large sheet.

2. Superior guide rail with linear bearing allows corrective and smooth corrugated paperboard feeding.

3. Automatic feeding unit works synchronously with printing roller, effectively ensuring high printing quality and reducing waste and inferior quality products.

4. Dust and scraps collecting device is designed. Air volume can be adjusted according to actual situation.

5. Motorized adjustment for side gauges and backstop is available. You can be free to set how to even the paper, manually or electrically. Working frequency can also be set up as you like.

6. The feeding rubber covered roller is constructed with double shaft at front and back part. The rubber coating combines soft inner layer with hard outer layer and features excellent flexibility and wear resistance.

7. Working speed and production quantity can be displayed in number.

8. The feeding unit is provided with servo drive lead edge feeder device. This device comes with following features.

1) High performance servo motor with instant reaction, high accuracy positioning, great system stability and long service life is applied. Electric cam is used to replace mechanical cam.

2) The feeding roll shaft is connected with the servo motor shaft by synchronous belt, thus eliminating any gap, improving feeding accuracy and avoiding off tracking.

3) Unique structure of quick-change semi-round is utilized so that the uniformity of feeding position can be ensured and the wear inconformity of feed roll can be avoided.

Printing Unit

Features of Printing Unit

1. The printing phase position and axial position is controlled by PLC. Dual operation to the corrugated board printing machine can be done using touch screen and electric button.

2. Auto zero set for print roller after being wiped is achieved.

3. The anilox roll moves synchronously with the feeding unit. That is, when the feeding unit starts or stops working, the anilox roll will be separate or connected in order with the print roll.

4. Start-stop function is set for ink roller and ink pump.

5. Foot switch is equipped at the printing unit, ensuring quick installation of printing plate and quick adjustment as well as convenience for printing plate changing and scrubbing.

6. The brake with electromagnetic clutch is specially mounted so that the gear can be automatically locked when there is wrong with the machine, thus avoiding the loss of zero.

7. Specially designed inking system can prevent ink spilling or misting and thereby protect printing quality.

8. Both print roll and pressure roll are made of superior alloy steel with specially chromed or hardened treatment.

9. Planetary gear adjusting mechanism with digital display function is used to adjust print roll phase and axial adjustment of the print roll can be done by the micro adjusting mechanism with digital display function.

Slotter Unit

Features of Slotter Unit

1. The slotter comes with preloading quick-adjusting structure that boasts self-locking function. Therefore, long term precision between slotter knife and shaft can be ensured, and damage to paperboard when slitting can be reduced.

2. The upper roll is coated with premium PU that will protect plasticity of cardboard from being damaged.

3. The upper and lower scoring wheels, upper and lower slotter knives, guide rolls can be adjusted synchronously.

4. The planetary gear type phase adjusting mechanism with digital display function is designed for motorized adjustment for slotting phase and slotter height.

5. The slotter knife is made of high quality alloy steel. Tooth edge comes in 7mm width.

6. Self lubricating and wear resistant guide block is typically equipped to ensure correct shift of the scoring wheels, slotter knife rolls and guide rolls as well as strengthen durability.

7. Both scorer roll shaft and slotter roll shaft are made of superior alloy steel with specially chromed or hardened treatment and the optimal balance point.

8. The operation panel is designed with switch buttons for starting and stopping paperboard feeding as well as starting the slotting machine.

Die Cutter

Features of Die Cutter

1. The die cutting machine is specially equipped with built-in speed compensation device. When the outer diameter of rubber mat changed, the device will automatically compensate the loss of linear speed, thus slowing wear of rubber mat down and achieving complete uniformity of size.

2. In standby time, the die cutting roll will be automatically separate with the rubber

mat roll, not only reducing load loss but also effectively prolonging service life of PU rubber and cutting die.

3. When the die cutter is running, the upper roll coated with rubber mat will be at automatic displacement state. Rotating speed of the upper roll differs from that of die cutting roll. Restorer is specially equipped to restore the rubber for many times. Such optimal designs to rubber mat roll will ensure high quality die cut workpiece.

4. Motorized adjustment with actual display is provided for die cutting roll phase and axial direction.

5. Two rolls are all made of high quality steel with fine machining and chromed or hardened treatment. Through fine revision, the dynamic balance of workpiece can reach the optimal state.

6. The machine is also equipped with a waste sweeping and transporting device which features anti-deviating function.

Auto Stacker

Features of Auto Stacker

1. The mechanical arms are mainly used for manually or automatically taking the slotted and die cut paperboard out to conveyor belt. Independent conveyor belt is employed, so the quantity of such mechanical arms can be easily determined.

2. Conveyor elevator is driven by a unique motor that features braking function. It is equipped with safety features and ergonomic design.

3. The conveyor belt is skid resistant, ensuring smooth conveying.

3. The paperboard support plate allows stacking height to reach 1600mm.

4. Air-pressure type support plate will automatically pop up to hold the stacked paperboard when the stacking height reaches expected level.

Technical Parameters

| Models | ||||||

| Max. machine speed (pcs/min) | 180 | 180 | 160 | 160 | 150 | 140 |

| Economic printing speed (pcs/min) | 140 | 140 | 130 | 130 | 120 | 110 |

| Max. sheet size (mm) | 1000×2000 | 1000×2400 | 1200×2400 | 1200×2800 | 1400×2800 | 1600×2800 |

| Min. sheet size (mm) | 280×685 | 280×685 | 300×685 | 300×685 | 350×685 | 400×685 |

| Sheet thickness range (mm) | 2.5-12 | 2.5-12 | 2.5-12 | 2.5-12 | 2.5-12 | 2.5-12 |

| Max. printing area (mm) | 950×2000 | 950×2400 | 1150×2400 | 1150×2800 | 1350×2800 | 1550×2800 |

| Standard flexo plate thickness (mm) | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 |

| Production Power(kW) | 22 | 22 | 30 | 30 | 40 | 45 |

| Total power(kW) (depending on printing units) | 40 | 40 | 45 | 45 | 45 | 50 |

| Color | 1-7 color | 1-7 color | 1-7 color | 1-7 color | 1-7 color | 1-7 color |