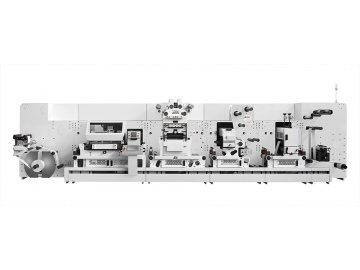

Automatic Cardboard Feeding Printer Slotter

In carton plants, traditional chain feeder printer slotter can not achieve large batch production, resulting in low efficiency and large labor intensity. Now, QISHENG automatic cardboard feeding printer slotter can help you to deal with such problem and makes mass production of corrugated cartons a breeze.

This automatic feeding printing and slotting machine employs a continuous paper feeding device that dwarfs manual single-sheet feeding and ensures straight paperboard traveling. It can not only increase working efficiency but also considerably reduce labor strength as well as rejection rate.

Configurations and Characteristics

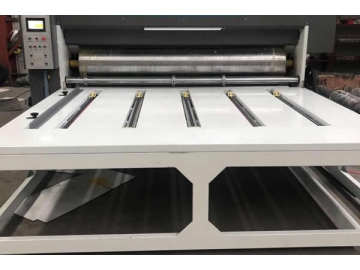

Automatic Feeding Unit

1. Screw rod adjusting mechanism is utilized for adjusting paperboard size. Only one person is needed to operate this device.

2. Adjustable paperboard stacking table can be compatible with all kinds of paperboard and ensures stable feeding.

2. The seamless feeding belt is made of superior rubber that shows large friction, low noise, easy maintenance, long service life and high economic benefit.

3. The paperboard feeder of this automatic cardboard feeding printer slotter is characterized by double tension control and thereby offers reliability.

4. The transmission draft is an embossing roller which can enhance friction with the belt, ensuring smooth and high speed paperboard conveying.

5. The feeding unit comes with an electromagnetic clutch braking mechanism which is controlled by optoelectronic signal.

6. Electric equipment is controlled by PLC.

7. Variable frequency drive motor can realize stable speed regulating operation.

Printing Unit

1. The printing unit features planetary transmission and electrical phase positioning with 360° adjustment in both dynamic and static condition.

2. When the color printing machine stops, the embossing roller can automatically break away from the printing plate.

3. Due to the auto spinning system of inking roller, printing ink of this automatic cardboard feeding printer slotter never dries up.

4. 1-4 colors can be combined as you like.

5. Pneumatic self-suction inking system can offer circulating ink to the corrugated cardboard printer slotter.

6. Illuminating system makes night working possible.

7. The printing roller is provided with a device that can make printing plate quickly installed.

8. Foot step electric switches are used to control the installation and disassembly of printing plates.

Slotting Unit

1. Slotting phase position comes with all-round electrical adjustment.

2. Four slotting knives are ganged.

3. High quality saw tooth slotting knives are used. So, smooth finish can be ensured.

4. The gear is made of 45# steel by high frequency quenching.

5. The corrugated carton slotter is immersed in lubricating oils and thereby serves for extremely long life.

6. The printing unit and slotting unit shift electrically and lock pneumatically.

Technical Data of Automatic Cardboard Feeding Printer Slotter

| Models (mm) | |||||

| Max. feeding size (mm) | 1200×2200 | 1400×2450 | 1400×2650 | 1600×2650 | 1800×2800 |

| Min. feeding size (mm) | 350×350 | 350×350 | 350×350 | 450×450 | 500×500 |

| Max. printing size (mm) | 1150×2000 | 1350×2200 | 1350×2400 | 1550×2400 | 1750×2600 |

| Min. slotting size (mm) | 7×300 | 7×350 | 7×350 | 7×400 | 7×450 |

| Max. slotting gap (mm) | 100 | 110 | 110 | 110 | 130 |

| Slotting knife thickness (mm) | 7 | 7 | 7 | 7 | 7 |

| Flexo plate thickness (mm) | 7 | 7 | 7 | 7 | 7 |

| Max. machine speed (sheet/min) | 70 | 70 | 70 | 60 | 50 |

| Max. height of feeding cardboard (mm) | Space between pusher-200 | Space between pusher -200 | Space between pusher -200 | Space between pusher -200 | Space between pusher -200 |

| Min. height of feeding cardboard (mm) | 300 | 350 | 350 | 450 | 500 |