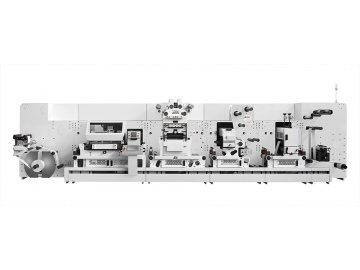

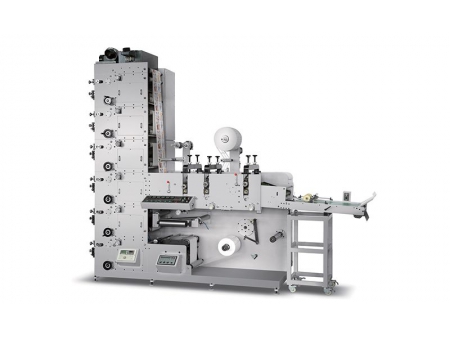

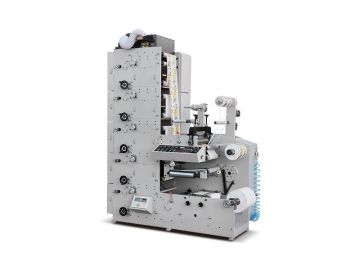

Automatic Flexo Printing and Die Cutting Machine

Our ZYM series automatic paper-feeding printer and die cutter is a new and ideal carton box machine developed in recent years for carton manufacturing industry. With this automatic flexo printer and die cutter, many processes from automatic paperboard feeding to printing, slotting, corner cutting, deburring, punching (any shape), etc. can be finished at one stroke.

The carton production line features compact structure, easy operation, simple adjustment, great performance and high efficiency. It is perfect for carton industry to produce high end cartons and is suitable for manufacturing all kinds of special cartons or carton boxes.

Units and Characteristics

Automatic Feeding Unit

1. The auto-feed unit of our automatic paper-feeding printer and die cutter utilizes screw rod adjusting mechanism to adjust paperboard size. It can be easily operated by only one person.

2. Adjustable paperboard stacking table is suitable for all kinds of board and ensures stable and precise feeding.

3. Delivery belt is seamless and made of premium rubber, thus embodying great friction, long lifespan, low noise, easy maintenance and high economic effectiveness.

4. Dual tension control makes this feeder more reliable.

5. The driving shaft is an embossing roller that can strength friction with the belt and smoothen board delivery.

6. Electromagnetic clutch braking mechanism ensures higher precision and safety as well. It can be controlled by optoelectronic signal which is synchronized with the main machine.

7. PLC control to electrical equipment heightens its automation.

8. Variable frequency motor is used, which can realize stable speed-regulating operation.

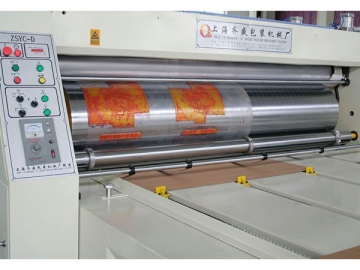

Printing Unit

1. The printing unit of our automatic paper-feeding printer and die cutter features planetary drive and electrical phase positioning with 360° adjustment in both dynamic and static condition.

2. When the printer stops, the embossing roller will automatically leave the printing plate.

3. Automatic spinning system of the inking roller keeps enough ink instead of drying up.

4. The color printer and die cutter is provided with air powered self-suction inking system.

5. 1-4 colors can be combined as you like.

6. Lighting system makes night working possible.

7. The print roller comes with a device that can make printing plate quickly installed.

8. The assembly and disassembly of printing plates can be controlled by our foot step switches.

Die Cutting Unit

1. Phase Position Adjusting Mechanism

1) It is constructed by a planetary gear.

2) The phase position of die cutting can be displayed numerically, making operation more convenient, precise and visualized.

3) With 360° phase adjustment by means of electric and digital methods, the phase modulation precision reaches ±0.10mm.

2. Cushion Roll Repair Mechanism

The cushion roll can be repaired by the electric grinding device. It can be repeated for 2-3 times

3. Speed Adjusting Mechanism

1) In order to ensure die cutting quality, a speed adjusting device is mounted outside the cushion roll gear so that the linear speed of the die cut roll and the cushion roll is the same.

2) Mechanical cushion roll can move 30mm toward left and right and it is equipped with radial differential gear. Therefore, wear to the roll can be evenly distributed and its service life can be thereby greatly extended.

4. Balance Adjustment for Higher Stability

Main Technical Parameters

| Models | ||

| Max. machine speed (sheet/min) | 60 | 60 |

| Max. feeding size (mm) | 1200×2200 | 1400×2500 |

| Max. printing size (mm) | 1200×2200 | 1400×2500 |

| Min. feeding size (mm) | 320×350 | 320×350 |

| Max. die cutting (mm) | 1200×1200 | 1400×2500 |

| Thickness of die cutter blade (mm) | 25.4 | 25.4 |

| Thickness of standard printing plate (mm) | 7 | 7 |

| Motor power (kW) | 11 | 15 |

| Feeding precision (mm) | ± 1.5 | ± 1.5 |

| Die-cutting precision (mm) | ± 2.0 | ± 2.0 |

| Color register precision (mm) | ± 1.5 | ± 1.5 |

| Dimensions (L×W×H) | 7400mm ×3800mm×2500mm | 7400mm×4200mm×2500mm |

| Color | 1-4color | 1-4color |

Notes: The degree of crook complies with national standard