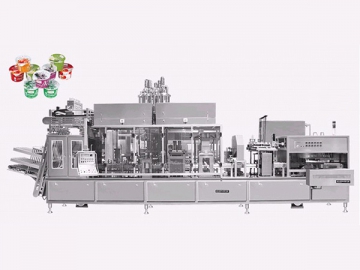

Tin Filling and Sealing Machine

TinFilling and Sealing Machine

Designed to combine the functions of conventional powder fillingmachines and open top can sealers, our tinfilling and sealing machine is a versatile milkpowder packaging machine which is dedicated for packing milk powder withtins. It is able tocomplete tin sorting, sterilization, powder weighing and filling,

Composition of Tin Filling and SealingMachine

I. Disk Tin Sorting Machine

The disk tin sorting machine of our tinned milk powder filling production line is used for sorting theempty tins and feeding the tins in single row.

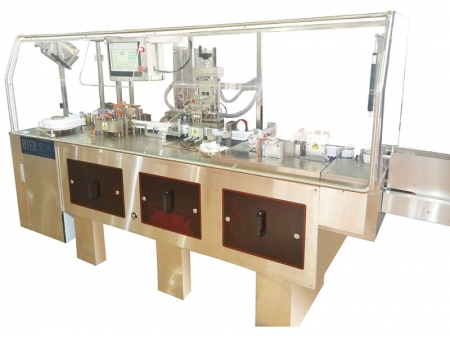

II. General Control Cabinet

The control cabinet of the tin filling and sealing machine is used to controlthe electrical system of the whole machine unit.

III. Empty Tin Purging and SterilizingSystem

This system can purge the empty tin and sterilize it through ultravioletradiation.

IV. Double Helix Weighing and FillingSystem

1. The double helix weighing and filling system adopts the Japanese Yamatoweighing technology.

2. The filling mechanism is equipped with an empty tin lifting device and avibrating compaction device.

3. Automatic dust removal mechanism, powder weighing mechanism and tin addingmechanism are configured to our tin filling and sealing machine.

4. The weighing and filling system can be connected to a computer or printingequipment.

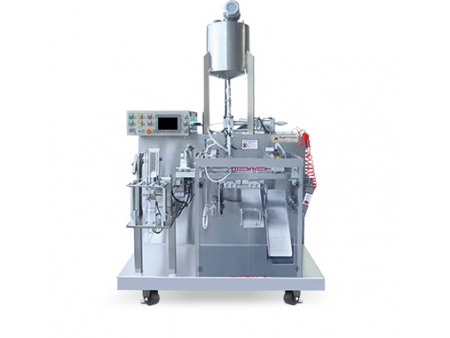

V. Fully Automatic VacuumNitrogen-Filled Tin Sealing Machine

1. The vacuum tin sealing machine consists of a fully automatic

2. The oxygen residue is less than 1.5%.

3. The negative pressure inside the tin is allowed to be set.

VI. Automatic Tin Turning Mechanism

This turning mechanism of our canned milk powder packaging machine can turn the tin 180° withoutusing any power.