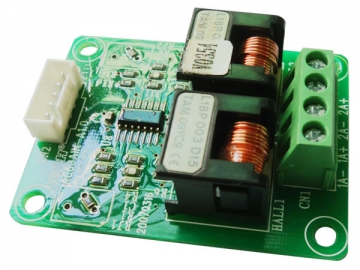

SF81 Injection Molding Machine Servo Drive

The SF81 injection molding machine servo drive is capable of double closed-loop control on pressure and speed, based on pressure and flow desired by different working conditions. Through pressure sensor, the servo control system reads the hydraulic circuit operational pressure and compares it with the pressure command from the host computer. Then, the system will automatically adjust the motor speed to complete the discharge of excess hydraulic oil without overflow valve. In this way, the energy is saved by 20% -60%. The servo drive is an ideal choice to accelerate investment return, as well as to improve injection efficiency and precision.

Voltage Rating of Injection Molding Machine Servo Drive

AC380V (three-phase power) 11 ~ 75KW

Features of Injection Molding Machine Servo Drive

1. Excellent Energy Conservation

In an ideal working condition, the energy saving rate can be 20%-60%, which excels the traditional hydraulic power control system.

2. Good Stability

The servo drive achieves precision closed-loop control of pressure and flow, and has greatly improved repeatability compared with conventional hydraulic control system.

3. Quick Dynamic Response

The servo control function is highly sensitive. The start or stop only takes about 0.1 second.

4. Large Load Capacity

A 3 times overload capacity ensures the stable operation of injection molding machine in frequent frequency fluctuation.

5. Multi-Channel Frequency Signal Input in Various Types

Proportional pressure signal and proportional flow signal are simultaneously accessible. The electrical signal source can be 0 ~ 1A / 0 ~ 5A, 0 ~ 10V / 0 ~ 5V, or 4 ~ 20MA / 0 ~ 20MA.

6. Rich Combination of Frequency Setting

The frequency can be given by the four types of combination of pressure signals and flow signals, which satisfies requirements of all the working conditions.

7. Quiet Operation

The servo drive has low noise during high carrier operation and is even quieter during low speed running. The noise is less than 70db under ideal conditions.

8. Reliable Pressure Maintaining

In closed-loop pressure control, the pressure maintaining can be more durable and more stable.

9. Double-Loop Design

The double-loop design of electricity supply and electricity conservation ensures continuous operation of the system, without affecting production.

10. Small Temperature Rise

During continuous running, the output of hydraulic oil is in proportion to avoid excess heat generation. Meanwhile, the hydraulic oil does not require cooling, to achieve significant water conservation.