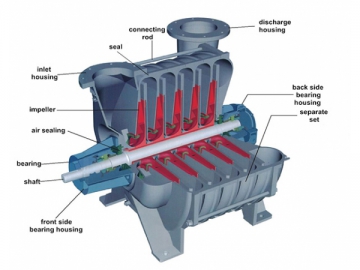

D Type Multi-stage Centrifugal Blower

About D Type

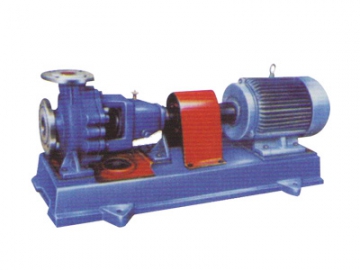

At first glance, the D type multi-stage centrifugal blower has compact structure and elegant appearance. It is easy to install and maintain, and works in high stability. This is series of squirrel cage blower is widely applied to sewage treatment, blast furnace, coal preparation plant, mine floatation, chemical gas, vacuum, and gas conveying, etc.

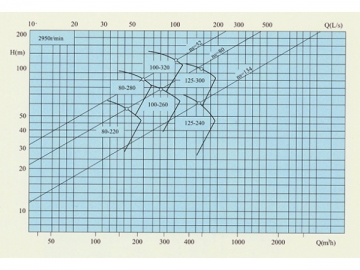

Specifications

1. Inlet flow: 20~250 m3/min

2. Discharge pressure: 1000~10000mmH2O

3. Vacuum: -800~5000 mmH2O

Features

1. Smooth operation: the design of the impeller is optimized so that the axial force is reduced to a minimum, and the efficiency is improved. By static and dynamic balance correction, the centrifugal blower runs smoothly. Without any extra vibration absorber, the vibration amplitude of bearings is ≤ 0.04mm.

2. Low noise: there is no mechanical friction when the blower is running. The reasonable curve of impeller reduces the sound to the minimum. Since noise generated by a multistage centrifugal blower is a high-frequency one, as long as there is an obstacle, the sound transmission will be significantly attenuated, so there is almost no noise outside the blower’s room.

3. Oil-free blower: Bearings are lubricated with grease, and the life of bearings can be more than two years. The centrifugal blower does not produce oil and gas in the operation. For some special applications, the blower may use molybdenum disulfide lithium grease lubricated bearings.

4. Impeller: the impeller is featured to have special curve to reduce internal leakage and improve volumetric efficiency.

5. Easy to be adjusted: the centrifugal blower has inlet butterfly valves regulating the flow, and outlet butterfly valves adjusting the pressure.

6. Drive method: the system is driven by asynchronous motor drive. The motor selection among different voltages depends on the user’s grid.

7. Sealing: inlet rings are equipped for impeller of every stage, and labyrinth seals are set between stages and at the two ends of housing to prevent gas leakage.

8. Cooling: because the impeller progressively compresses gas, the temperature of outlet housing is much higher than that of inlet housing. Both air cooling and water cooling structures are designed for exhaust bearing pedestal to prolong bearings’ service life.

9. Bearing temperature alarm: attachments of centrifugal blower include a temperature control box, connected via PT100 with bearings. When the bearing temperature exceeds the set temperature, the temperature control box will automatically send alarms.

10. Transmission: coupling transmission is adopted, but depending on the equipment and processes, different transmission mode may also be selected.

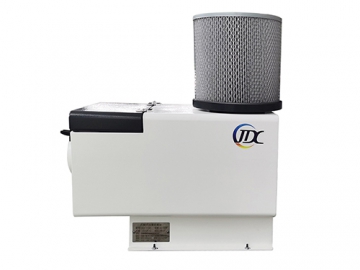

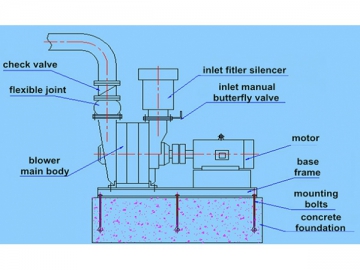

Main Body of D Type Multi-stage Centrifugal BlowerAssembling Drawing of D Type Blower Package

| Art No. | Inlet Airflow (m3/min) | Inlet Pressure kpa | Inlet Tempera- ture (℃) | Discharge Differential Pressure | Rotary Speed (r/min) | Shaft Power (KW) | Motor Power (KW) | Blower Weight (kg) | |

| kpa | mm.h2o | ||||||||

| 20 | 98 | 20 | 39.2 | 4000 | 2950 | 20 | 30 | 2200 | |

| 20 | 98 | 20 | 49 | 5000 | 2950 | 24 | 30 | 2300 | |

| 20 | 98 | 20 | 58.8 | 6000 | 2950 | 29 | 37 | 2600 | |

| 20 | 98 | 20 | 68.6 | 7000 | 2950 | 34 | 45 | 3000 | |

| 25 | 98 | 20 | 39.2 | 4000 | 2950 | 25 | 30 | 2200 | |

| 25 | 98 | 20 | 49 | 5000 | 2950 | 29 | 37 | 2300 | |

| 25 | 98 | 20 | 58.8 | 6000 | 2950 | 34 | 45 | 2600 | |

| 25 | 98 | 20 | 68.6 | 7000 | 2950 | 39 | 55 | 3000 | |

| 30 | 98 | 20 | 39.2 | 4000 | 2950 | 28 | 37 | 2200 | |

| 30 | 98 | 20 | 49 | 5000 | 2950 | 33 | 45 | 2300 | |

| 30 | 98 | 20 | 58.8 | 6000 | 2950 | 41 | 55 | 2600 | |

| 30 | 98 | 20 | 68.6 | 7000 | 2950 | 43 | 55 | 3000 | |

| 35 | 98 | 20 | 39.2 | 4000 | 2950 | 32 | 37 | 2200 | |

| 35 | 98 | 20 | 49 | 5000 | 2950 | 37 | 45 | 2300 | |

| 35 | 98 | 20 | 58.8 | 6000 | 2950 | 46 | 55 | 2600 | |

| 35 | 98 | 20 | 68.6 | 7000 | 2950 | 55 | 75 | 3000 | |

| 40 | 98 | 20 | 39.2 | 4000 | 2950 | 36 | 45 | 2200 | |

| 40 | 98 | 20 | 49 | 5000 | 2950 | 44 | 55 | 2300 | |

| 40 | 98 | 20 | 58.8 | 6000 | 2950 | 54 | 75 | 2600 | |

| 40 | 98 | 20 | 68.6 | 7000 | 2950 | 61 | 75 | 3000 | |

| 45 | 98 | 20 | 39.2 | 4000 | 2950 | 40 | 55 | 2200 | |

| 45 | 98 | 20 | 49 | 5000 | 2950 | 48 | 55 | 2300 | |

| 45 | 98 | 20 | 58.8 | 6000 | 2950 | 56 | 75 | 2600 | |

| 45 | 98 | 20 | 68.6 | 7000 | 2950 | 65 | 75 | 3000 | |

| 50 | 98 | 20 | 39.2 | 4000 | 2950 | 45 | 55 | 2200 | |

| 50 | 98 | 20 | 49 | 5000 | 2950 | 55 | 75 | 2300 | |

| 50 | 98 | 20 | 58.8 | 6000 | 2950 | 66 | 75 | 2600 | |

| 50 | 98 | 20 | 68.6 | 7000 | 2950 | 74 | 90 | 3000 | |

| 50 | 98 | 20 | 78.5 | 8000 | 2950 | 80 | 90 | 3200 | |

| 55 | 98 | 20 | 39.2 | 4000 | 2950 | 50 | 55 | 2200 | |

| 55 | 98 | 20 | 49 | 5000 | 2950 | 60 | 75 | 2300 | |

| 55 | 98 | 20 | 58.8 | 6000 | 2950 | 71 | 90 | 2600 | |

| 55 | 98 | 20 | 68.6 | 7000 | 2950 | 79 | 90 | 3000 | |

| 55 | 98 | 20 | 78.5 | 8000 | 2950 | 90 | 110 | 3200 | |

| 60 | 98 | 20 | 39.2 | 4000 | 2950 | 53 | 75 | 2200 | |

| 60 | 98 | 20 | 49 | 5000 | 2950 | 65 | 75 | 2300 | |

| 60 | 98 | 20 | 58.8 | 6000 | 2950 | 78 | 90 | 2600 | |

| 60 | 98 | 20 | 68.6 | 7000 | 2950 | 88 | 110 | 3000 | |

| 60 | 98 | 20 | 78.5 | 8000 | 2950 | 96 | 110 | 3200 | |

| 65 | 98 | 20 | 39.2 | 4000 | 2950 | 58 | 75 | 2200 | |

| 65 | 98 | 20 | 49 | 5000 | 2950 | 70 | 90 | 2300 | |

| 65 | 98 | 20 | 58.8 | 6000 | 2950 | 78 | 90 | 2600 | |

| 65 | 98 | 20 | 68.6 | 7000 | 2950 | 93 | 110 | 3000 | |

| 65 | 98 | 20 | 78.5 | 8000 | 2950 | 105 | 132 | 3200 | |

| 70 | 98 | 20 | 39.2 | 4000 | 2950 | 61 | 75 | 2600 | |

| 70 | 98 | 20 | 49 | 5000 | 2950 | 74 | 90 | 2800 | |

| 70 | 98 | 20 | 58.8 | 6000 | 2950 | 88 | 110 | 3200 | |

| 70 | 98 | 20 | 68.6 | 7000 | 2950 | 101 | 110 | 3700 | |

| 70 | 98 | 20 | 78.5 | 8000 | 2950 | 108 | 132 | 4200 | |

| 75 | 98 | 20 | 39.2 | 4000 | 2950 | 66 | 75 | 2600 | |

| 75 | 98 | 20 | 49 | 5000 | 2950 | 79 | 90 | 2800 | |

| 75 | 98 | 20 | 58.8 | 6000 | 2950 | 93 | 110 | 3200 | |

| 75 | 98 | 20 | 68.6 | 7000 | 2950 | 106 | 132 | 3700 | |

| 75 | 98 | 20 | 78.5 | 8000 | 2950 | 116 | 132 | 4200 | |

| 80 | 98 | 20 | 39.2 | 4000 | 2950 | 71 | 90 | 2600 | |

| 80 | 98 | 20 | 49 | 5000 | 2950 | 87 | 110 | 2800 | |

| 80 | 98 | 20 | 58.8 | 6000 | 2950 | 104 | 132 | 3100 | |

| 80 | 98 | 20 | 68.6 | 7000 | 2950 | 110 | 132 | 3700 | |

| 80 | 98 | 20 | 78.5 | 8000 | 2950 | 117 | 160 | 3900 | |

| 85 | 98 | 20 | 39.2 | 4000 | 2950 | 76 | 90 | 2600 | |

| 85 | 98 | 20 | 49 | 5000 | 2950 | 92 | 110 | 2800 | |

| 85 | 98 | 20 | 58.8 | 6000 | 2950 | 109 | 132 | 3100 | |

| 85 | 98 | 20 | 68.6 | 7000 | 2950 | 116 | 160 | 3700 | |

| 85 | 98 | 20 | 78.5 | 8000 | 2950 | 123 | 160 | 3900 | |

| 90 | 98 | 20 | 39.2 | 4000 | 2950 | 80 | 90 | 2600 | |

| 90 | 98 | 20 | 49 | 5000 | 2950 | 96 | 110 | 2800 | |

| 90 | 98 | 20 | 58.8 | 6000 | 2950 | 106 | 132 | 3200 | |

| 90 | 98 | 20 | 68.6 | 7000 | 2950 | 121 | 160 | 3700 | |

| 90 | 98 | 20 | 78.5 | 8000 | 2950 | 135 | 160 | 4200 | |

| 100 | 98 | 20 | 39.2 | 4000 | 2950 | 89 | 110 | 2600 | |

| 100 | 98 | 20 | 49 | 5000 | 2950 | 108 | 132 | 2800 | |

| 100 | 98 | 20 | 58.8 | 6000 | 2950 | 126 | 160 | 3100 | |

| 100 | 98 | 20 | 68.6 | 7000 | 2950 | 134 | 160 | 3700 | |

| 100 | 98 | 20 | 78.5 | 8000 | 2950 | 146 | 200 | 3900 | |

| 110 | 98 | 20 | 39.2 | 4000 | 2950 | 98 | 110 | 2600 | |

| 110 | 98 | 20 | 49 | 5000 | 2950 | 120 | 160 | 2800 | |

| 110 | 98 | 20 | 58.8 | 6000 | 2950 | 129 | 160 | 3200 | |

| 110 | 98 | 20 | 68.6 | 7000 | 2950 | 148 | 200 | 3700 | |

| 110 | 98 | 20 | 78.5 | 8000 | 2950 | 165 | 200 | 4200 | |

| 120 | 98 | 20 | 49 | 5000 | 2950 | 132 | 160 | 4400 | |

| 120 | 98 | 20 | 58.8 | 6000 | 2950 | 154 | 200 | 4900 | |

| 120 | 98 | 20 | 68.6 | 7000 | 2950 | 162 | 200 | 5300 | |

| 120 | 98 | 20 | 78.5 | 8000 | 2950 | 176 | 200 | 6000 | |

| 120 | 98 | 20 | 88.3 | 9000 | 2950 | 193 | 220 | 6600 | |

| 120 | 98 | 20 | 98 | 10000 | 2950 | 212 | 250 | 7000 | |

| 130 | 98 | 20 | 49 | 5000 | 2950 | 135 | 160 | 4400 | |

| 130 | 98 | 20 | 58.8 | 6000 | 2950 | 163 | 200 | 4900 | |

| 130 | 98 | 20 | 68.6 | 7000 | 2950 | 170 | 200 | 5300 | |

| 130 | 98 | 20 | 78.5 | 8000 | 2950 | 190 | 220 | 6000 | |

| 130 | 98 | 20 | 88.3 | 9000 | 2950 | 208 | 250 | 6600 | |

| 130 | 98 | 20 | 98 | 10000 | 2950 | 228 | 280 | 7000 | |

| 140 | 98 | 20 | 49 | 5000 | 2950 | 146 | 160 | 4400 | |

| 140 | 98 | 20 | 58.8 | 6000 | 2950 | 165 | 200 | 4900 | |

| 140 | 98 | 20 | 68.6 | 7000 | 2950 | 183 | 220 | 5300 | |

| 140 | 98 | 20 | 78.5 | 8000 | 2950 | 204 | 250 | 6000 | |

| 140 | 98 | 20 | 88.3 | 9000 | 2950 | 224 | 280 | 6600 | |

| 140 | 98 | 20 | 98 | 10000 | 2950 | 245 | 280 | 7000 | |

| 150 | 98 | 20 | 49 | 5000 | 2950 | 161 | 200 | 4400 | |

| 150 | 98 | 20 | 58.8 | 6000 | 2950 | 185 | 220 | 4900 | |

| 150 | 98 | 20 | 68.6 | 7000 | 2950 | 198 | 250 | 5300 | |

| 150 | 98 | 20 | 78.5 | 8000 | 2950 | 220 | 280 | 6000 | |

| 150 | 98 | 20 | 88.3 | 9000 | 2950 | 245 | 280 | 6600 | |

| 150 | 98 | 20 | 98 | 10000 | 2950 | 265 | 315 | 7000 | |

| 160 | 98 | 20 | 49 | 5000 | 2950 | 167 | 200 | 4400 | |

| 160 | 98 | 20 | 58.8 | 6000 | 2950 | 182 | 220 | 4900 | |

| 160 | 98 | 20 | 68.6 | 7000 | 2950 | 209 | 250 | 5300 | |

| 160 | 98 | 20 | 78.5 | 8000 | 2950 | 234 | 280 | 6000 | |

| 160 | 98 | 20 | 88.3 | 9000 | 2950 | 257 | 315 | 6600 | |

| 160 | 98 | 20 | 98 | 10000 | 2950 | 280 | 355 | 7000 | |

| 180 | 98 | 20 | 49 | 5000 | 2950 | 190 | 220 | 5100 | |

| 180 | 98 | 20 | 58.8 | 6000 | 2950 | 225 | 280 | 5600 | |

| 180 | 98 | 20 | 68.6 | 7000 | 2950 | 245 | 280 | 6000 | |

| 180 | 98 | 20 | 78.5 | 8000 | 2950 | 265 | 315 | 6600 | |

| 180 | 98 | 20 | 88.3 | 9000 | 2950 | 290 | 355 | 7000 | |

| 180 | 98 | 20 | 98 | 10000 | 2950 | 321 | 400 | 7200 | |

| 200 | 98 | 20 | 49 | 5000 | 2950 | 210 | 250 | 5300 | |

| 200 | 98 | 20 | 58.8 | 6000 | 2950 | 245 | 280 | 5700 | |

| 200 | 98 | 20 | 68.6 | 7000 | 2950 | 289 | 355 | 6300 | |

| 200 | 98 | 20 | 78.5 | 8000 | 2950 | 295 | 355 | 6700 | |

| 200 | 98 | 20 | 88.3 | 9000 | 2950 | 325 | 400 | 7200 | |

| 200 | 98 | 20 | 98 | 10000 | 2950 | 355 | 400 | 7500 | |

| 250 | 98 | 20 | 49 | 5000 | 2950 | 264 | 315 | 5300 | |

| 250 | 98 | 20 | 58.8 | 6000 | 2950 | 320 | 400 | 5700 | |

| 250 | 98 | 20 | 68.6 | 7000 | 2950 | 265 | 450 | 6300 | |

| 250 | 98 | 20 | 78.5 | 8000 | 2950 | 388 | 450 | 6700 | |

| 250 | 98 | 20 | 88.3 | 9000 | 2950 | 410 | 500 | 7200 | |

| 250 | 98 | 20 | 98 | 10000 | 2950 | 441 | 500 | 7500 | |

| 300 | 98 | 20 | 49 | 5000 | 2950 | 294 | 355 | 5300 | |

| 300 | 98 | 20 | 58.8 | 6000 | 2950 | 356 | 450 | 5700 | |

| 300 | 98 | 20 | 68.6 | 7000 | 2950 | 430 | 500 | 6300 | |

| 300 | 98 | 20 | 78.5 | 8000 | 2950 | 441 | 500 | 6700 | |

| 300 | 98 | 20 | 88.3 | 9000 | 2950 | 481 | 560 | 7200 | |

| 300 | 98 | 20 | 98 | 10000 | 2950 | 528 | 630 | 7500 | |

| 350 | 98 | 20 | 49 | 5000 | 2950 | 345 | 450 | 6600 | |

| 350 | 98 | 20 | 58.8 | 6000 | 2950 | 402 | 500 | 7800 | |

| 350 | 98 | 20 | 68.6 | 7000 | 2950 | 461 | 560 | 9000 | |

| 350 | 98 | 20 | 78.5 | 8000 | 2950 | 515 | 630 | 9500 | |

| 350 | 98 | 20 | 88.3 | 9000 | 2950 | 565 | 630 | 9900 | |

| 350 | 98 | 20 | 98 | 10000 | 2950 | 625 | 710 | 10500 | |

| 400 | 98 | 20 | 49 | 5000 | 2950 | 394 | 450 | 6600 | |

| 400 | 98 | 20 | 58.8 | 6000 | 2950 | 461 | 500 | 7800 | |

| 400 | 98 | 20 | 68.6 | 7000 | 2950 | 532 | 710 | 9000 | |

| 400 | 98 | 20 | 78.5 | 8000 | 2950 | 586 | 710 | 9500 | |

| 400 | 98 | 20 | 88.3 | 9000 | 2950 | 645 | 800 | 9900 | |

| 400 | 98 | 20 | 98 | 10000 | 2950 | 705 | 800 | 10500 | |