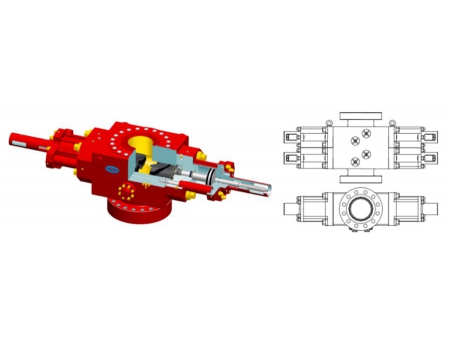

Ram BOP

The type S ram BOP employs pressure bearing element made of superior alloy steel for outstanding strength and impact toughness during oil drilling. For powerful sealing performance, the oil well control device adopts combined seal ring for the sealing of the side outlet, to achieve outstanding pressure maintaining capacity. In addition, the ram BOP has the following features.

1. The well drilling equipment adopts floating type or integrated ram for reliable sealing performance and convenient replacement.

2. It employs concealed oil circuit. The load bearing hinge is separated from the hydraulic hinge.

3. For rapid installation, the hinge of the single ram BOP is designed in simple structure.

4. To reduce the peak stress, the side of the housing chamber for the double ram blowout preventer is engineered in arc shape and adopts arc periphery for transition.

5. The ram chamber can be installed with ram assembly of the same type purchased from other countries.

6. Coming in compact structure, the ram BOP has smaller volume, compared with overseas offshore drilling tool.

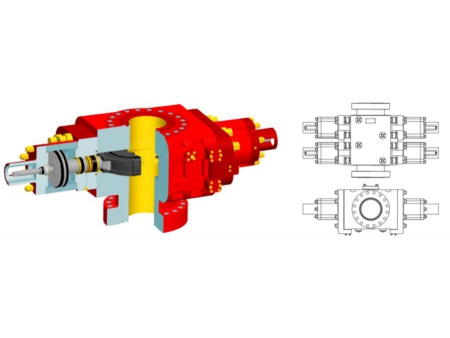

Designed and manufactured according to API Spec 16A and GB/T20174 standard, the type U ram BOP is configured with rams in diversified specifications. The ram is installed with superior front elastomeric seal, top elastomeric seal, and middle flange seal, capable of satisfying the requirement for the oil field jobs in poor environment, such as low temperature, high temperature, or acid condition.

Features

1. The pressure bearing element for the ram BOP adopts forge piece for good strength and impact toughness. In addition, defect caused by forging can be avoided, also.

2. Employing combined sealing, the flange operation under the control of the hydraulic system is realized. Moreover, the ram replacement of the oil rig handling tool is rapid and convenient.

3. Installed with auxiliary cylinder, the oil drilling ram BOP has the same function, but smaller volume, compared with other traditional shear ram BOP.

4. This ram BOP comes with large reserve elastomeric seal. The self-feed sealing performance brings more convenience to the users.

5. Thanks to the manual locking system for the hydraulically controlled ram BOP, the ram will be in closed state in case there is hydraulic oil loss.

6. Conveniently, the manual and the hydraulic locking device, as well as the auxiliary cylinder can be installed flexibly at the location required according to practical situation of the clients.

7. The ram chamber of the manually controlled ram BOP is suitable for the foreign ram assembly designed for the petroleum equipment of the same type.