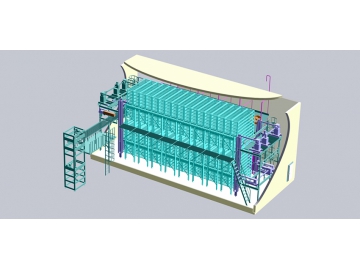

Structural Steel Hot-Dip Galvanizing Line

Our structural steel hot-dip galvanizing line is developed on the basis of the existing advanced technologies for the hot-dip galvanization in industries like electricity transmission, transportation, telecommunication, and so on. As a piece of structural steel galvanizing equipment, it can galvanize a variety of structural steel parts, such as transmission tower, microwave tower, utility pole, lighting mast, road side fence, sign post, and so on.

This structural steel hot-dip galvanizing line is designed in accordance with related domestic and international standards, meeting all your requirements for the process flow, production capacity and techniques. As a kind of eco-friendly and energy saving galvanizing equipment, it can maintain a good production environment, reliable production performance, and gives long service life.

In addition, the structural steel hot-dip galvanizing line has many other highlights, including immersion heated ceramic galvanizing kettle, enclosed acidic rinsing, enclosed galvanization, flux regeneration, bio-degreasing technique, and some other environmental friendly technical techniques.

Parameter

Material: structural steel, Q235B steel, Q345B steel

Galvanizing temperature: 440℃~470℃

Zinc solution components: pure zinc, galfan alloy

Galvanizing kettle size: 4~13m length × 1~3m height × 1~2.5m width

Energy: natural gas, liquefied petroleum gas, electricity

Coating standards: ISO1461: 2009(E), GB-T13912-2002

Process flow

Workpiece preparation – alkaline degreasing (bio-degreasing) – water rinsing – acid pickling – water rising – flux solution – drying – hot-dip galvanizing – water cooling – passivation – inspection – finishing

Main technique and machine

Enclosed pretreatment, bio-degreasing, acidic mist cleaning equipment, drying furnace driven by the waste heat, enclosed galvanizing furnace with immersion ceramic galvanizing kettle, dust collecting bag, waste acid recovery equipment, flux regeneration

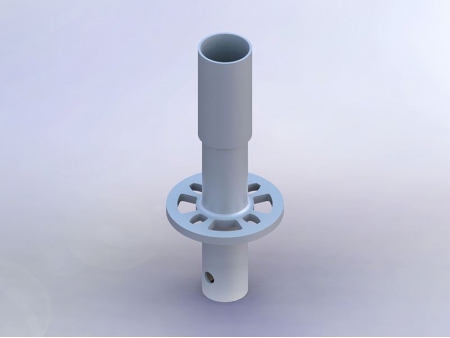

- Lifting sling

- Lifting sling

- Lifting sling

- Support frame for lifting sling

- Pretreatment bath

The pretreatment bath comes with steel structural frame and internal PPH plate lining. Thus the anticorrosive performance and high strength can be both achieved. A steam heat exchanger or PTFE electric heating device is available for the degreasing bath and flux solution bath.

- Enclosed pretreatment workshop

- Enclosed pretreatment workshop

The APVX plate is used to enclose the pretreatment tank. The acid fume will be extracted from the enclosed room to the washing tower. The acid fume will be collected and absorbed in a spraying tower (sodium hydroxide solution). As high as 50% hydrochloric acid can be absorbed. The hydrochloric acid concentration in the treated exhaust is only 1.25mg/m3, while the exhaust flow rate is 0.05kg/h, meeting the related environmental protection standard.

We introduced the bio-degreasing technology and equipment from Sweden. By this technique, microorganisms are used for swallowing all the grease on the workpiece surface. It is eco-friendly, clean, and energy saving. No Chemicals will be needed, and no exhaust will be generated.

- Electric drying furnace

- Gas drying furnace

The galvanizing furnace comes with a immersion heated ceramic galvanizing kettle. The immersion heating technique features rapid heating speed, low energy consumption, high efficiency, stable working performance, and long service life. Specifically, the service life could be more than 10 years. The adoption of ceramic galvanizing kettle could save you 10% ~ 15% zinc in comparison to the iron kettle. The body of the ceramic galvanizing kettle has three layers of heat conservation structure, making the outside temperature lower than 50℃. Thus the working environment for workers is greatly improved.

- Ceramic galvanizing kettle

- Iron galvanizing kettle

- Electric ceramic galvanizing kettle

- Gas iron galvanizing kettle

- Enclosed ceramic galvanizing kettle

- Enclosed ceramic galvanizing kettle

The enclosed galvanizing technique adopts an special de-dusting shield to enclose the galvanizing kettle. An automatic door is available at both the inlet and outlet. When a workpiece enters the de-dusting shield, the automatic door at the inlet will close. The galvanizing process can be monitored from the view windows at both sides of the de-dusting shield. All the fume produced during the galvanizing process, through a top-mounted draught fan, can be extracted to the filter bag for the dust colleting. You can also choose to lead the fume to a washing tower, in which the atomization spraying technique is adopted to neutralize the hazardous particles and deposit the dust. Thus the exhaust can become much cleaner.

During the pretreatment process, the oxidation-reduction method and ammonium hydroxide solution are used for the removal of Fe2 ion from the flux solution. The filtered solution will return to the flux solution bath. The output of the neutralization reaction is ammonium chloride, so this iron removing method is both economic and eco-friendly. In addition, an automatic control system is designed to control the addition of chemicals, ensuring the ferrous ion stays below 1g/L. Thus the zinc consumption is lowered about 4%.

- Galvanizing of electric power fittings

- Galvanizing of iron tower for wind

turbine