Waste Acid Recovery System

Waste acid recovery system

Our waste acid recovery system is based on the vacuum distillation technique. The solution containing FeCl2 and HCL will be heated in a vacuum environment, thus the HCL and water will be evaporated. The vapor then will be condensed and collected to get low concentration HCL. In the original solution, non-volatile FeCl2 will become saturated. Then the solution will be cooled to reduce the FeCl2 solubility. During this step, FeCl2 will turn into crystal, and get separated from the solution.

Parameter of the waste acid recovery system

1. Water solution component: Fe2 : 80~120 g/L

HCL: 120~150 g/L

2. Waste solution processing capacity: 5~100 ton/day

3. Output: FeCl2·4H2O and 8~11% HCL solution (The concentration of regenerated acid depends on the concentration of the waste acid. In general, the concentration of new acid is 3%-4% higher than the waste acid.

4. Pollution: After the treatment by our equipment, no pollutant should be in the sewage.

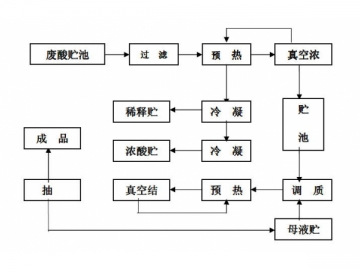

Process flow of the waste acid recovery system

- Waste acid pool

- Filtering

- Pre-heating

- Vacuum concentration

- Dilution Pool

- Condensing

- Storage Pool

- Finished product

- Concentrated acid pool

- Condensing

- Pumping

- Vacuum crystallization

- Pre-heating

- Tempering

- Mother solution pool

Feature of our waste acid recovery system

1. The hydrochloric acidrecovery machines have great anti-corrosive and high-temperature resistance. They can endure the corrosion of the hydrochloric acid and chloride at high working temperature.

2. The structure of this waste acid recycling device is well designed. The great strength won’t get deformed or damaged at a high temperature and with a certain pressure.

3. All the parts and accessories come with excellent quality. The exchange and repairing are both very convenient. The core parts are made of imported materials. The small fault rate is quite low, and the fixing time is less than 1 hour. The medium scale maintenance cycle is longer than 10 months, while the trouble-free cycle is longer than 6 months.

4. The control system of our waste acid recovery system is quite user-friendly. An interlocking device is available for the monitoring of temperature, pressure, fluid weight, and flow rate, making the usage and inspection quite convenient.