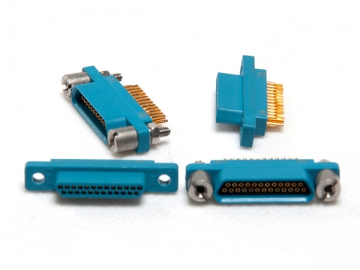

Twist Pin Contacts

The twist pin contact is a unique type of connector pin that comprises two layers of helically coiled wires. The inner layer consists of 3 strands of wires reversely wound with respect to the outer layer. The outer helix uses 7 wire strands made of beryllium bronze. Strands are bonded together at both ends to form the pin through a process known as fusion welding. One end of the pin is crimped into the wire barrel of the electrical connector. The other end protrudes outside the connector shell. Halfway along the length of the pin is a bulge with a diameter slightly larger than the inner diameter of the socket connector it fits in. When the pin is inserted into the socket, the bulge is depressed and forced to extend its length helically along the pin axis. This means when the bulge makes contact with the inside of the socket, it provides 7 points of contact within the connection interface.

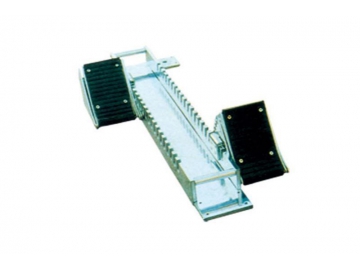

The connection between the pin and the wire barrel is made by using an automatic crimping machine. The resultant crimp contact provides 4 points of contact between the pin and the barrel, with maximum contact strength up to 30N. Unique crimp structure assures trouble-free contact performance and great resistance to vibration and shock. Shock tests find that the crimp contact is able to withstand shock with a peak acceleration of 150g. Please note that shocks are applied to the crimp contact in three directions for 3000 times.

Features of Twist Pin Contact

The twist pin contact provides much flexibility in mating and unmating. It requires very low insertion force while allowing a smooth insertion. Typical characteristics of the twist pin contact include the following.

1. As the flexibility twist pin contact goes into socket, it quickly adapts itself to the inside geometry of the socket.

2. Along with the elastic contraction of the bulge comes the extension of the pin length along its centerline.

Due to the low pull and push force required by the pin, it exhibits high mating reliability. Experiments indicate the twist-pin contact can endure 1000 mating cycles. At the end of the experiments, the tested contact shows no obvious changes in terms of contact resistance and insertion force.

If our standard twist-pin contact does not appeal to you, please contact us to access the custom design service.