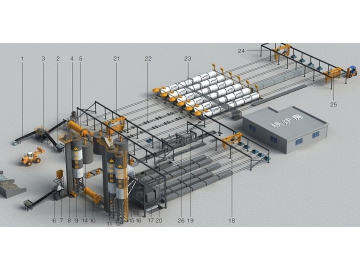

Dry Mortar Production Line with Bucket Elevator

DryMortar Production Line with Bucket Elevator

CONLY dry mortar production line with bucket elevatoris highly characterized by low investment. This automatic productionline needs no operatives and is well-suited for mid-small productionplant. Installation is custom to your specific plant areas.

Advantages

1. Energy Efficiency

This dry mortar production line features small power consumption, becauseundesired conditions, such as feed back and material digging, are rarely seen.

2. Wide Application

This is derived from fewer requirements on materialtypes and properties. Our building materialproduction system handles everything from powder, particles to bulkmaterials.

3. Long Service Life

Bucket elevator adopts flow-through feeding method, resulting in lessmechanical abrasion.

Main Components

1. Feeding and Storing System

Generally speaking, dry mortar production needs various materials includingcement, fly ash, sand, calcium carbonate and certain additives. We normallyutilize tank cars for feeding of cement and fly ash, while sand and othermaterials are fed by bucket elevator and conveyed to silos by screw conveyor.

Silos are made from quality steel and can be customized. Level indicator isinstalled for automatic read-out.

2. Weighing and Batching System

In this dry mortar production line, Scale A comes with screw conveyor and isused to weigh main materials (A1, A2, A3, A4, A5, A6). Proportion value can bepre-set via touch screen and each material will be fed by exclusive screwconveyor. Feeding of next material will be automatically activated when theprevious material reaches pre-set value.

Scale B comes with small scale range for measuring additives (B1, B2,

3. Lifting System

After weighing, materials are transported to bucketelevator, and will be lifted up to silos in the middle for procedures followed.

4. Mixing System

Proper mixing system is determined by your requirements and materialproperties. Our double-shaft paddle mixer isthe frequently seen choice in dry mortar manufacture industry. This mixingsystem involves the utilization of two vertically mixing shafts in same size,rotating reversely at same speed.

Moreover, we specially place paddle on mixing shaft, whereby mixing materials inradial direction, hoop direction and shaft direction. Combined cycle deliversthe import benefits in the form of even mixing in short time.

5. Weighing and Packing System

We mainly offer valve bag and open bag packing machine. Selection is determinedby your requirements. The valve bag packing machine delivers automatic sealing,while open bag packing system requires bag sewing machine.

Bag Size: 18

Packing Speed: 3-4 bags/min

Bulk Bag Filler Capacity: 500

Bulk Bag Filler Speed: 5 bags/hour

6. Dust Cleaning System

In our dry mortar production line, we place pulsejet fabric filters with fan at feeding section and packing section.Filter area varies 7

On the top of silos, we adopt cylinder-type dustcollector, offering filtration capacity of 7

.jpg

.jpg

"01.jpeg"

"02.jpeg"

"03.jpeg"

"04.jpeg"

"05.jpeg"

"06.jpeg"

"07.jpeg"

"08.jpeg"

Title: Dry Mortar Production Line with Bucket Elevator | CONLY

Keywords: Dry mortar production line, bucket elevator, building materialproduction system, dust collector, double-shaft paddle mixer

Description: CONLY dry mortar production line withbucket elevator is highly characterized by low investment. This automaticproduction line needs no operatives and is well-suited for mid-small productionplant.