Powder and Fluid Dosing and Mixing Equipment

Powderand Fluid Dosing and Mixing Equipment

CONLY powder and fluid dosing and mixing equipmentcan be offered in various outlays and structures, whereby catering to demandingneeds from industries of plastic, feedstuff, food, chemical, metallurgy and buildingmaterials, etc.

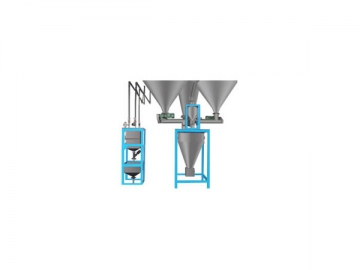

Main Components

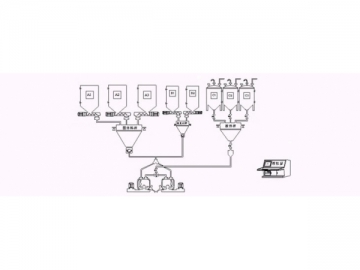

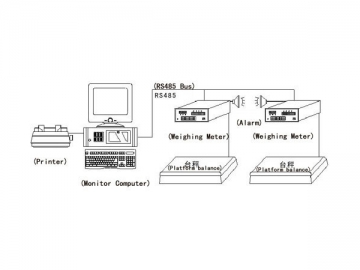

Our automatic dosing and mixing system involves theutilization of IPC as the core control equipment. RS-485 bus isresponsible for reliable connection among all electric scales, pulse counter,thermometer and PLC.

In this powder and fluid dosing and mixing equipment, we apply PLC to realizeaccurate control on relay or contactor of related devices. Based on receivedworking conditions, IPC implements processing procedures programmedaccordingly. Free adjustment can be done to related equipment by receiving datafrom all instruments.

ControllingContent

1. Combineddosing and mixing of several powder weighing scales and fluid weighing scales

2. Temperatureof two mixing systems

3. Valve ofbatch scale feeder

4. Operating time and discharge of mixingmachine

5. Temperature test and control of mixer

6. Formula input and modification

7. Configuration of processing technology related to dosing and mixing

Features of Powder and Fluid Dosing andMixing Equipment

1. This food mixing scale utilizes oneIPC to deliver accurate control on several batching scales and thermometer.

2. RS-485 bus greatly simplifies connection among instrument and computer, andenhances reliability in a holistic approach.

3. We employ several scales varying in measuring range and structures, so thatthis chemical dose mixer is applicable forpowders and fluids.

4. Shock resistant structure is ruggedly designed for industrial applications.

5. IPC is operator and maintenance friendly.

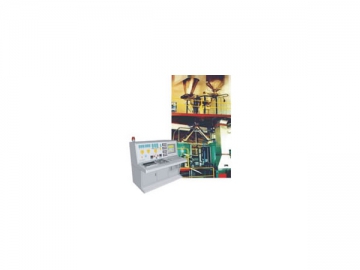

6. In order for exceptional fast and accurate control, this feedstuff dosing and mixing equipment usescomputer to handle production configuration, formula input, productionstatistics, historical queries and process control.

7. Thanks to diagnostic software in this powder and fluid dosing and mixingequipment, you avail from fast read-out on system failures and reduced downtime.

8. Variable frequency drive controls feeding system to enhance dynamicaccuracy.

9. According to production needs, our powder and fluid dosing and mixingequipment can be controlled automatically, semi-automatically and manually.

10. Superior electronic components isresponsible for over 20,000 hours of failure-free performance.

You Benefits

1. Due to fully automatic control, the accuracy of dosing and mixing is0.2%-0.5% higher than manual operation.

2. Reduced labor workload comes with decreased failure.

3. All sealed production process delivers clean environment.

4. Comprehensive information and data assist you with cost calculation.

5. This dosing and mixing system delivers positive factors to qualification orreexamination of ISO9000 quality management system.

Title: Powder and Fluid Dosing and Mixing Equipment | CONLY

Keywords: Powder dosing and mixing equipment, fluid dosing and mixingequipment, food mixing scale, chemical dose mixer, feedstuff dosing and mixingequipment

Description: CONLY powder and fluid dosing and mixingequipment can be offered in various outlays and structures for industries ofplastic, feedstuff, food, chemical, metallurgy and building materials, etc.