Shot Blasting Machine for Steel Sheets and Profiles

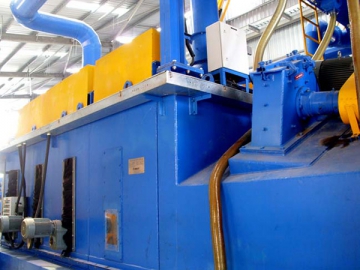

The shot blasting machine for steel sheets and profiles has a quite self-explanatory name, indicating that it is developed for the derusting and painting treatment of steel plates, steel profiles and structural parts used for ships, automobiles, locomotives, bridges, engineering machines and so on. This wheel blast machine could be tailored according to customers’ needs, and its work flow is mainly constituted by preheating, shot blasting, painting and drying.

System Configuration

As an effective steel plate preservation line, our shot blasting machine offers reliable surface preparation solution since it is scientifically designed and meticulously crafted.

The blast chamber, pre-blastroom and post-blastroom are all constructed from steel plate and profile steel via welding, and they take high chromium steel plates as lining material to protect themselves. These plates are connected together by protective nuts, so it is very easy to replace them.

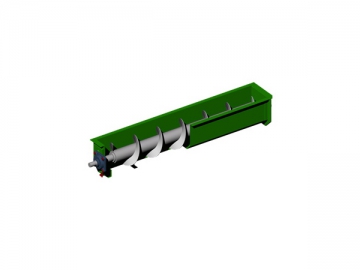

2. Blast Wheel AssemblyComposed of QY360 blast wheel, turbine, belt pulley, V-belt and bed plate, the blast wheel assembly provides a jet of abrasives to thoroughly clean the surface of metal parts.

3. Abrasive Reclamation SystemOur shot blasting machine’s abrasive reclamation system is primarily made up of screw conveyor, bucket elevator, sand separator, pneumatic valve, abrasive delivery chute and so on.

4. Roller Conveying SystemThe roller conveying system is further divided into in-feed rollers, pre-blastroom rollers, blast chamber rollers, post-blastroom rollers, intermediate rollers and out-feed rollers.

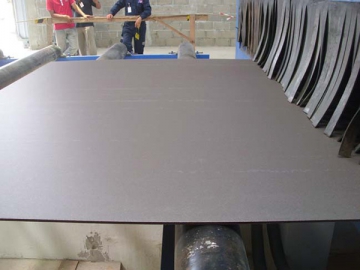

5. Steel Plate Cleaning RoomOur shot blasting machine takes advantage of a cleaning unit to remove remaining abrasives from steel plates after shot blasting, and this is a two-stage process that includes brushing and air blowing.

6. Automatic Painting and Paint Mist Handling SystemThis system consists of spray booth, spray trolley, detection device, drive mechanism, painting pump, paint mist filtration unit, harmful gas adsorption unit and other parts, and it is controlled either automatically or manually. In addition, the painting pump, spray gun, spray nozzle and phototubes are all imported to ensure reliable working.

7. Paint Drying System

Endowed with drying tunnel, electrical heater, slat conveyor, draught fan and other parts, our paint drying system dries newly painted plates continuously as they are moving in the tunnel, thus making the paint in a touch dry or solid dry condition.

This metal surface cleaning equipment makes use of a two-stage dedusting process to remove dust, and this dust removal system is formed by cartridge filter, blower, settling box and pipelines.

9. Electrical Control SystemOur shot blasting machine is controlled by a Siemens PLC controller, and its electrical devices are all manufactured by CHINT. Moreover, there is a switch used to adjust working mode between automatic and manual, while inter-locking, self-locking and failure warning functions help to guarantee our product’s safe running.

Technical Data of Shot Blasting Machine for Steel Sheets and Profiles| Item | Unit | | | | |

| Effective cleaning width | mm | 800 | 1200 | 1500 | 2000 |

| Feed port size of blast chamber | mm | 1000×400 | 1400×400 | 1700×400 | 2200×400 |

| Workpiece length | mm | 1200-12000 | 1200-1600 | 1200-12000 | 1200-12000 |

| Roller conveying speed (stepless control) | m/min | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 |

| Steel plate thickness | mm | 3-60 | 3-60 | 1.5-60 | 3-60 |

| Profile size | mm | 800×300 | 1000×300 | 1500×300 | 2000×300 |

| Abrasive consumption | kg/min | 4×180 | 4×250 | 4×250 | 6×250 |

| Initial abrasive quantity | kg | 4000 | 4000 | 4000 | 4500 |

| Height adjustment range of rolling brush | mm | 200 | 200 | 350 | 450 |

| Air requirement | m3/h | 22000 | 17560 | 19000 | 19550 |

| Machine size | mm | 25017×4500 ×9015 | 12180×4250 ×7095 | 15200×5370 ×6797 | 30650×6850 ×9095 |

| Total power (without dust removal system) | kW | 90 | 78.3 | 113.5 | 156.6 |