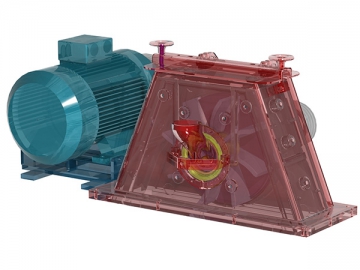

Barrel Blast Machine

The barrel blast machine is a highly efficient shot blasting machine, and it is newly developed to better meet the market demand.

Feature

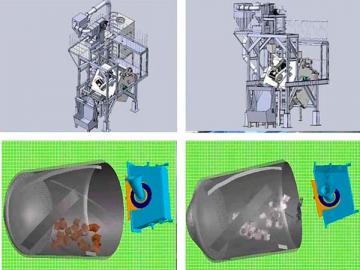

This rotating barrel wheel blast machine makes its barrel rotate and swing when propelling abrasive media, so work pieces inside the barrel are tumbled sufficiently without part-to-part collision, thus realizing uniform coverage, short cleaning time and high working efficiency.

Application

Owing to the properties illustrated above, our barrel blast machine fits for batch-type blast cleaning of small- or medium-sized castings and forgings whose weight is less than 15kg, and it is exceptionally suitable for thin-walled metal parts. In addition, this batch barrel machine could be customized.

The barrel blast machine is a piece of complicated metal surface cleaning equipment, and it is formed by the following parts.

1. BarrelFitted with highly efficient blast wheel assembly, the barrel rotates and swings while abrasives are being sprayed. So, work pieces inside are tumbled for consistent blast pattern exposure.

2. Barrel Body

It is hydraulically controlled, and keeps steady during work.

The blast wheel assembly is primarily composed of blast wheel and turbine. In particular, our barrel blast machine is outfitted with QY360 blast wheel which is manufactured using Japanese technology, and it is cantilever driven by a 30kW turbine.

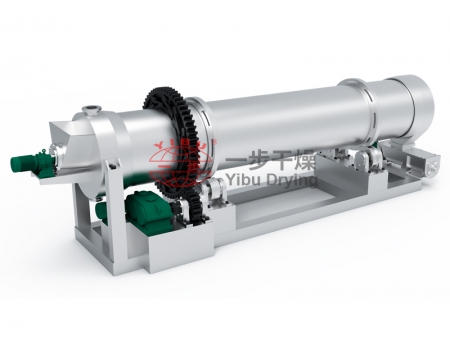

4. Bucket ElevatorThe bucket elevator is made up of cycloidal speed reducer, belt pulley (upper and lower), rubber belt, abrasive hopper, housing, tensioning device and so on.

5. Sand Separator

Our sand separator uses air to remove sand, mill scale and broken shots from useable abrasives.

Our barrel blast machine sets an abrasive silo underneath the sand separator to store abrasives, thus making it possible to continuously feed abrasives into the blast wheel.

7. Screw ConveyorConstructed from thick-walled seamless steel tubes, the screw shaft is processed as a whole after welding to ensure good concentricity at both ends. On the other hand, screw blades are made from 8-mm-thick 16Mn steel to extend their service life.

8. Dust Removal System

The barrel blast machine’s dust removal system is an integration of dust collector, blower, settling box, cyclone dust extractor and pipelines, and it adopts two stage dedusting process. The bag-type dust collector is a filtration device that uses fabrics to collect dust, and it is constructed from high-quality felting to offer excellent dust removal result. More specifically, over 99% of submicron sized dust will be eliminated.

As indicated by its name, the loading device is used to transport work pieces into the barrel before cleaning.

10. Electrical Control SystemThe barrel blast machine is controlled by a PLC controller, and its control mode is switchable between automatic mode and manual mode. Moreover, a touch screen is equipped, while inter-locking and other protection functions are also offered.

Technical Data of Barrel Blast Machine| Item | Data |

| Barrel size (Ф×L) | Ф1500×1600mm |

| Max. load weight | 1200kg |

| Max. piece weight | 40kg |

| Max. work piece length | 600mm |

| Air requirement | 5000m3/h |

| Total power | 57kW |