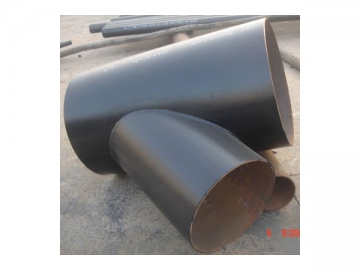

Pipe Tee

It is well known that most straight tees on the market are welded and the welding lines are readily worn away. Therefore, these pipe tees are not suitable for the connection of pressure pipes. N-STEEL straight tees (OD1/2’’-60’’), however, are formed in one-step molding process, depending on best-in-class equipment and technologies which can improve product quality, shorten processing time and reduce costs.

The pipe tee is a kind of industrial pipe fitting. It is mainly used to either combine or split a fluid flow. Most of common tees except reducing tees have the same inlet and outlet sizes. According to different materials, N-STEEL is available with carbon steel tees, stainless steel tees, alloy steel tees, etc. Owing to superior quality and low prices, our products are very popular in United States,United Arab Emirates, Brazil and South Korea.

Industrial Processes

Bending, squeezing, pressing, forging, machining and more

Industries Served

IN-STEEL pipe tees are extensively used in the oil refining, chemical, nuclear power, thermal power, coal, chemical, pharmaceutical, food, textile, shipbuilding, marine engineering, military, aviation and other industries.

| Item | Production range | |

| Seamless tee | Welding tee | |

| Outside diameter | 1/2"-32" | 6"-60" |

| Wall thickness | 4mm-200mm | |

| Product types | Straight tee, Reducing tee | |

1. Straight Tee

Size Seamless straight tee: 1/2"~32"DN15~DN800

Welding straight tee: 6"~60" DN150~DN1500

Wall Thickness

SCH10, SCH20, SCH30, STD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160, XXS, SCH5s, SCH20s, SCH40s, SCH80sMax. Wall thickness: 200mm

Available Materials

Carbon steel: ASTM/ASME A234 WPB-WPC

Alloy steel: ASTM/ASME A234 WP 1-WP 12-WP 11-WP 22-WP 5-WP 91-WP 911

Stainless steel: ASTM/ASME A403 WP 304-304L-304H-304LN-304N

ASTM/ASME A403 WP 316-316L-316H-316LN-316N-316Ti

ASTM/ASME A403 WP 321-321H ASTM/ASME A403 WP 347-347H

Low temperature steel: ASTM/ASME A402 WPL 3-WPL 6

High performance steel: ASTM/ASME A860 WPHY 42-46-52-60-65-70

Standards

ASME B16.9-2007, ASME B16.25-2007

MSS SP 75-2008, MSS SP 43-2008

EN10253-1-1999, EN10253-2-2007, EN10253-3-2008, EN10253-4-2008

DIN2615-1-1992, DIN2615-2-1992

BS1640-1-1962, BS1640-2-1962, BS1640-3-1968, BS1640-4-1968, BS1965-1-1963

GOST17376-2001

AFNOR NF A 49-289-1990, AFNOR NF A 49-170-1-1999, AFNOR NF A 49-170-2-2009, AFNOR NF A 49-170-3-2009, AFNOR NF A 49-170-4-2009ISO3419-1981, ISO5251-1981

JIS B2311-2009, JIS B2312-2009, JIS B2313-2009

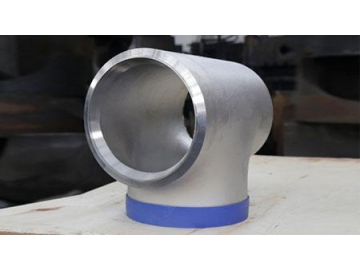

2. Reducing Tee

Size

Seamless reducing tee: 1/2"~32"DN15~DN800Welding reducing tee: 6"~60"DN150~DN1500

Wall Thickness

SCH10, SCH20, SCH30, STD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160, XXS, SCH5s, SCH20s, SCH40s, SCH80sMax. Wall thickness: 200mm

Available Materials

Carbon steel: ASTM/ASME A234 WPB-WPC

Alloy steel: ASTM/ASME A234 WP 1-WP 12-WP 11-WP 22-WP 5-WP 91-WP 911

Stainless steel: ASTM/ASME A403 WP 304-304L-304H-304LN-304N

ASTM/ASME A403 WP 316-316L-316H-316LN-316N-316Ti

ASTM/ASME A403 WP 321-321H ASTM/ASME A403 WP 347-347H

Low temperature steel: ASTM/ASME A402 WPL 3-WPL 6

High performance steel: ASTM/ASME A860 WPHY 42-46-52-60-65-70