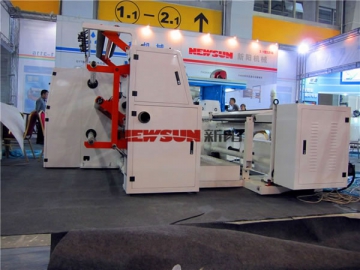

FHQE Series High-Speed Slitting and Rewinding Machine

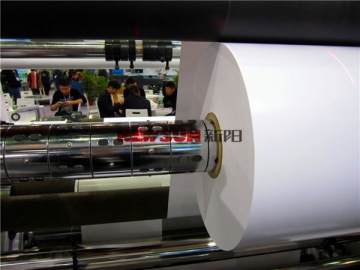

The FHQE series high-speed slitting and rewinding machine emerges as the multi-functional slitting and rewinding equipment. Thanks to synchronous belt drive, this thin film processing machine offers remarkable stability and reduced noise generation. Moreover, unwinding stand is incorporating with extra-wide belt conveyer to drastically reduce transport abrasion.

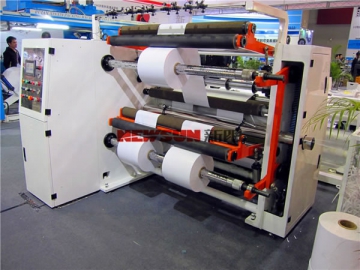

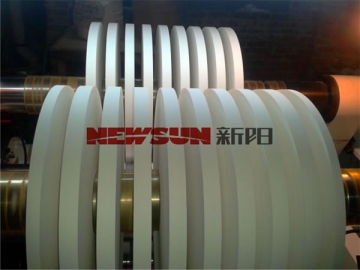

Our high-speed slitting and rewinding machine has proven itself for processing all kinds of roll materials such as BOPP, PET, CPP, PVC, PE, electrochemical aluminum foil, coated aluminum foil, adhesive sticker and paper, etc. This protective film slitter rewinder precisely cuts single-layer rewind into double layers, three layers or four layers. Cutting width and layers are allowed for custom adjustment.

Advantages

1. Imported PLC and touch screen are introduced to the electrical control system in this series of high-speed slitting and rewinding machine. Configuration can be readily adjusted and operation parameters are displayed for easy read-out.

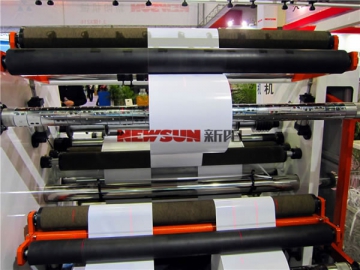

2. Rewinding unit adopts vector frequency converter, and unwinding unit enjoys magnetic powder brake. Both units employ PLC for automatic calculation of roll diameter, resulting in automatic tension control.

3. This adhesive sticker slitting and rewinding machine comes with independent unwinding stand and hydraulic feeding system. Shaftless material loading delivers impressive efficiency.

4. Rewinding unit collaborates with duplex differential slip rewind inflatable shafts. The dual slitting method consists of razor blades and circular knives for smooth cutting. Air blowing system collects waste materials.

5. Automatic unwinding guide is available in this high-speed slitting and rewinding machine.

6. Our aluminum foil slitting and rewinding equipment delivers value-added functions including metering, diameter calculation and automatic shutdown, etc.

7. The paper slitting and rewinding system is the perfect combination of mechanical, electrical and hydraulic designs, and has protective devices for user safety.

| Model | ||

| Unwinding Width | 1300mm | 1500mm |

| Max. Unwinding Diameter | Φ1000/1200mm | Φ1000/1200mm |

| Max. Rewinding Diameter | φ600mm | φ600mm |

| Slitting Width | 40mm-1300mm | 40mm-1500mm |

| Paper Core Inner Diameter | 76mm | 76mm |

| Max. Rewinding Speed | 400m/min | 400m/min |

| Error Correction Accuracy | ≤0.40mm | ≤0.40mm |

| Thickness of Raw Material | 0.012-0.2mm | 0.012-0.2mm |

| Total Power | 12kW | 15kW |

| Dimensions (L×W×H) | 3600mm×4500mm×1850mm | 3600mm×4900mm×1850mm |

| Weight | 3500kg | 4000kg |