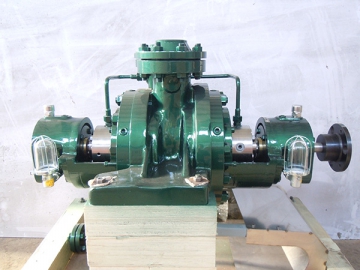

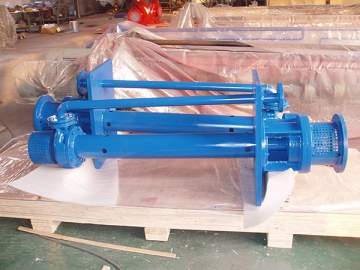

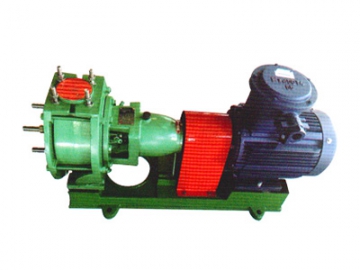

API610 BB2 Pump (Double Suction Centrifugal Pump)

Properties

Size : 1.5-10 inches

Flow rate: 2.5-600m3/h

Head : 30-300m

Temp.: -45-420°C

Materials: Cast steel, SS304, SS316, SS316Ti, SS316L, CD4MCU

This API610 BB2 pump is a single-stage centrifugal pump which is designed with a double-supporting structure.

Structural Features of API610 BB2 Pump

1. Pump Casing

Of a radial split structure, this single stage centrifugal pump is quite suitable to convey high-temperature, high pressure, combustible or explosive noxious liquids. Supported by the centerline, it could minimize the transformation and displacement which are caused by thermal expansion-contraction. At the same time, the double-vortex of this API610 pump design could perfectly keep the radial force balanced.

2. Flange

Flanges of the suction opening and discharge opening, both mounted vertically upward, are integrated with the entire pump by integral casing. Their dimensions and working pressures meet ANSI standard of 300Pounds per Square Inch. According to the temperature and materials to be conveyed, the maximum working pressure for this API pump could be 5Mpa.

3. Process Pump

In order to ensure good quality and reliable performance, each unit of this API610 BB2 pump is designed with a casing made of cast iron whose hydrostatic pressure could be 7MPa(experimental data).

4. Shaft Seal

The shaft seal and pump cover of this single-stage double-suction API pump are cast integrally. The former could adopt packing seal, balanced mechanical seal, bellows mechanical seal or cartridge mechanical seal. There is an optional water cooling jacket which could be mounted at the external surface of the shaft seal cavity. This device is quite necessary if the pump is meant to handle liquids of temperature higher than 66°C or hydrocarbon of temperature higher than 150°C. It could keep the media at their original temperature as long as it is filled with low pressure vapor or other thermal insulating materials. If you need a unit equipped with this device, please make your requirement clear. The cooled-water inlet joint Rc1/2 is mounted below the pump cover and the outlet joint Re 1/2 above the cover. So are the vapor inlet joint and outlet joint.

5. Impeller

The impeller of this single-stage double-suction centrifugal pump is integrally cast. It rotates synchronously with the rotors which are supported by both ends.

6. Seal Rings

The casing seal ring and impeller seal ring we adopt in this API610 BB2 pump are both replaceable standard parts. The two seal rings besides the impeller are intentionally designed with different dimensions. To be more specific, the one next to the thrust bearing is smaller than the other one. This design could lead to a slight axial force, keeping the shaft being stretched for all time and preventing rotors from stirring.

7. Bearing Housing

There are two bearing housings equipped at the two ends of this API BB2 pump, both of which, made of cast iron and cast steel, share the same size with each other. Fixed onto the bracket by screws, each bearing housing will be equipped with a set of radial bearings at the end adjacent to the coupling and two sets of thrust ball bearings (back to back arrangement) at the other end. All those bearings could be properly lubricated by the oil slinger. Moreover, both bearing housings are attached with axial cooling fins which could effectively cool air within the pump(t≦120℃). Air cooling device(t=120℃-160℃)and water cooling device(t≧260℃)are available for customers as well. Especially, the former is quite suitable for water-deficient areas or areas where water quality is quite poor.

8. Fan

When the fan of this radial split centrifugal pump is working, it will take the place of dust disk. That is a unique feature of this API process pump and the related techniques have been patented in US.

9. Oil Pointer and Oil Ring

The bearing housing of this industrial centrifugal pump is equipped with plastic oil pointer and oil ring to monitor and control the oil level.

10. Dust Disc

There are two dust discs mounted at both ends of the bearing housing of this API 610 BB2 pump, effectively preventing dusts and moistures from entering the pump and avoiding oil leakage. If any bearing get broken, these discs could support it for some time. Additionally, the one near to the pump is attached with air wings that could not only cool the shaft seal but also prevent bearings from being heated.

11. Components for Lengthened Flexible Diaphragm Coupling

The DSJH process pump is equipped with a lengthened flexible diaphragm coupling which enable users to dismantle impellers, bearings, shaft and shaft seal without removing the suction and discharging pipes. At the mean time, this coupling together with the shaft forms a taper, quite easy to dismantle.

Advantages of API610 BB2 Pump

1. This API BB2 Pump thoroughly meets the API610 standard and enjoys highly reliable performance.

2. It enjoys high working efficiency which helps it compete with world-class pumping units.

3. This single-stage double-suction centrifugal pump is highly interchangeable with pumps of other models, making the maintenance and repair much easier.

4. The shaft housing is attached with heat radiators at its external surface which could not only promote the cooling performance but also increase the rigidity of the housing. The available cooling devices for the radiator include air-cooling device, fan cooling device and water-cooling device.

5. As this centrifugal pump unit is designed with a radial split casing, its impellers could be removed easily from the two ends of the pump, making the maintenance and inspection simpler.

6. Its double-vortex design prevents the radial force from come into being.

7. The double-suction structure of this pump ensures slight axial force within the pump.

8. The two seal rings besides the impeller are intentionally designed with different dimensions. To be more specific, the one next to the thrust bearing is smaller than the other one. This design could lead to a slight axial force, keeping the shaft being stretched for all time and preventing rotors from stirring.

9. The coupling and the shaft form a taper, quite easy to dismantle.

10. The shaft seal could adopt the packing seal, single-faced and double-faced mechanical seal, tandem mechanical seal and bellows mechanical seal.

Application of API610 BB2 Pump

This single-stage double-suction centrifugal pump perfectly meets the API610 standard and has been widely used in the oil refinery, petrochemical and chemical industries as well as conveyance or oil and other products.