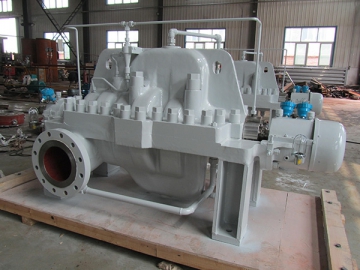

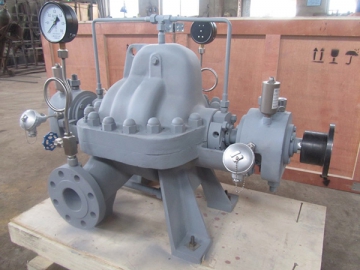

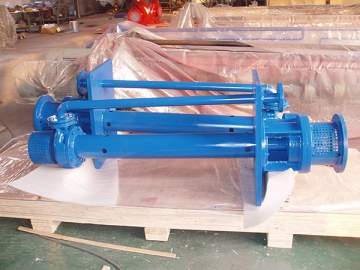

API610 VS6 Pump (Multistage Centrifugal Pump)

Properties

Nominal Diameter (DN) : 40-200mm

Flow rate (Q): 0~ 800 m3/h

Head (H): 0~800m

Working pressure (P): 0~10.0MPa

Temp. (T) : -180~180°C

The API610 VS6 pump is a multi-stage cantilever pump which, of a radial split structure, is designed with a double-layer housing. It is manufactured strictly according to the API610 standard and meets such industrial standards as AD Code (Technical Rules for Pressure Vessels), ASME Boiler and Pressure Vessel Code and other international industrial standards for this pumping equipment.

Structural Features of API610 VS6 Pump

1. This API cantilever pump is equipped with single-suction radial impellers which are designed with a single-layer casing. Especially, the first-stage impellers are usually suction impellers.

2. The axial force is borne by the radial ball bearing. When the differential pressure is large, this force will be balanced by the balancing drum.

3. The outer casing of this API610 cantilever pump only bears the inlet pressure, whose length, as well as the installation depth of the pump, is determined by your requirements for NPSH. If this API VS6 pump is going to be mounted on a container or connected with a pipe flange, its outer casing is unnecessary for it.

4. The centripetal thrust ball bearing in the bearing housing could slide smoothly with the help of lubricating oil for there is an automatic lubricating system inside. The liquid power lubrication radial bearing is mounted at the inlet section of the pump.

5. When its installation depth reaches to a certain level, this API VS6 pump will be equipped with immediate shaft bearings whose supporting devices adopt the liquid lubrication.

6. The available shaft seals for this multi-stage pump are single-faced mechanical seal and tandem mechanical seal, both of which are attached with cooling, flushing or sealing liquid systems.

7. The suction pipe and discharge pipe of this API 610 VS6 pump are mounted on the upper part of the flange, forming a 180 degree angle. Other layouts for the two pipes are also applicable. Flanges meeting the DIN standard or GB standard are available for this multi-stage cantilever pump. The connecting thread of auxiliary pipes could adopt the G-thread, Rc or R thread.

8. This radial split multi-stage pump is driven by the motor through the flexible coupling (or lengthened flexible coupling). The mounting type of its motor is V1.

9. The pump rotates anticlockwise if you look at it from the drive section.

Application of API610 VS6 Pump

This multi-stage cantilever pump could be used to transport clean or slightly-contaminated low temperature/high temperature neutral or corrosive liquids. It has been widely applied in the oil refinery, petrochemical plants, power generation stations, marine oilfield and some other low-temperature projects.