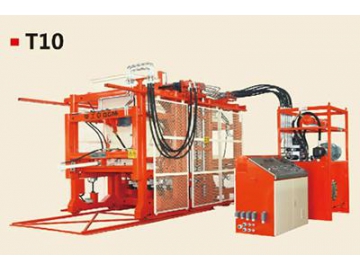

QT4-30 Semi-Automatic Block Making Machine

When you order from Noah Intelligent Equipment, you get more than just a high quality block making machine. What we deliver as well are consistent services available throughout the profitable lifetime of the brick machine. With only a small investment, brick and block suppliers can get a highly versatile brick machine that pays for itself in a short period. The concrete block machine takes your waste slag or fly ash and converts it into useful slabs, Dutch bricks, perforated bricks, and interlocking pavers such as dog-bone pavers and zigzag pavers. Depending on the types of blocks you want to produce, NOAH would design corresponding molds to accomplish the task. For more information about specific mold models, please navigate to related pages on our website.

Features of QT4-30 Block Making Machine

1. CHNT electrical system is incorporated into the block making machine for durability and stability.

2. Imported hydraulic parts and sealing components allow for free adjustment of hydraulic flow and pressure according to specific working conditions. This is critical to the machine’s ability to precisely control the movement of key parts.

3. The main body of this semi-automated brick making machine is a high-strength, precision-machined casting that has been through special welding process to gain good rigidity, vibration resistance, and longevity.

4. Guided by 4 columns, the compression plate (also known as the tamper head, which tamps down or compact the concrete mix in the mold) moves smoothly along the column with high accuracy.

5. Vibratory worktable keeps agitating the mix for uniform distribution while high pressure is applied to the material, compressing it into shapes. The oscillating screen allows the material to flow through the hopper outlet and reach the mold smoothly.

6. Short molding cycle ensures high production efficiency. The resulting block is solid, robust and in accurate sizes.

7. The block making machine brings together mechanical, electrical, and hydraulic features into an integrated unit that delivers high repeatability from one molding cycle to the next. That is the reason why the machine could deliver a lower scrap rate.

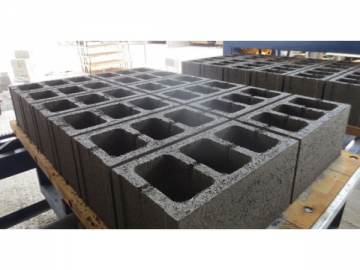

8. Various types of bricks and blocks can be made using this semi-automated brick making machine including the likes of perforated bricks, hollow bricks, curbstones, paving bricks, turf blocks, slope bricks and more.

9. With several modifications, the equipment can used to as a paver block making machine to produce colored concrete paver blocks, and pavers topped with face mix.

Note that the face mix is a term referring to the top layer of concrete which is added on top of the compacted base. The whole is compressed and vibrated yet again.

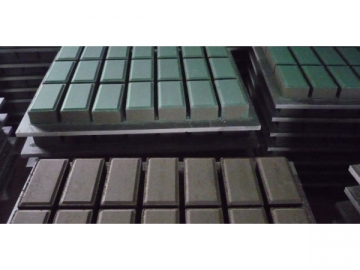

Specifications| Brick Specifications | Samples | pcs/mold | pcs/h | pcs/8h | Year (300 days) |

| Blocks 390×190×190mm 71pcs/m3 | 4 | 480 | 3840 | 16225m3 | |

| Blocks 390×100×190mm 135pcs/m3 | 8 | 720 | 5760 | 12799m3 | |

| Dutch Bricks 200×100×60mm 50pcs/m2 | 14 | 1680 | 13440 | 80640m2 | |

| Dog-Bone Pavers 200×165×60mm 30pcs/m2 | 8 | 960 | 7680 | 76039m2 | |

| Zigzag Pavers 225×112.5×60mm 40pcs/m2 | 12 | 1440 | 11520 | 87493m2 | |

| Perforated Bricks 240x115x90 402pcs/m3 | 12 | 1440 | 11520 | 3.45 million pcs | |

| Solid Bricks 240x115x53 683pcs/m3 | 24 | 2880 | 23040 | 6.91 million pcs |

| Dimension | 4850×4650×2250(mm) |

| Pallet Size | 850×550×16(PVC plate) |

| Weight | 4000kg |

| Vibration Frequency | 50-90Hz |

| Maximum Excitation Force | 50KN |

| Molding Cycle | 30S |

| Installed Capacity | 21KW |