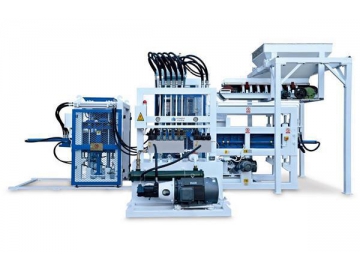

QT6-15 Automatic Block Making Machine

QT6-15 automatic block making machine is typically used to produce various specifications of floor brick and air brick. Listed below are 3 major parts that make up the block production system.

Electrical System of Automated Block Making Machine

This electrical system uses PLC to provide precise control. It also comes with I/O ports for data transfer. The PLC system provides security control and fault diagnosis functions. Taking advantage of advanced technologies behind electrical control, we at NOAH have developed a hydraulic control system that automatically adjusts the oil pressure across the hydraulic circuit and synchronizes the demoulding movements of all molds. Thanks to the precision control, the entire concrete block production system can deliver high repeatability with durable products that pass the quality check.

Hydraulic System of Automated Block Making Machine

The cooling system along the hydraulic circuit serves as a guarantee that the hydraulic fluids are maintained at a proper temperature and viscosity. This is critical in ensuring hydraulic system stability and reliability. State-of-the-art hydraulic oil filtration system removes impurities from oil, safeguarding the reliability hydraulic parts and ultimately that of the entire hydraulic system. Imported sealing elements and high-performing proportional valves contribute to the precise control over movements of key parts.

Vibratory Compaction System of Automated Block Making Machine

1. The vibratory compaction system is comprised of the framework, vibration exciter, vibration isolator, compactor, and demoulding device. Vibration is produced in the vertical plane towards a preset direction. Inside the mold, the concrete mix is compacted into shape.

2. Unique feeder mechanism spreads out material on multiple axes. Else, a oscillating rake mechanism is used to dislodge the arching of concrete material thereby allowing rapid, smooth material flow. Before material placement occurs, vibration applies to it.

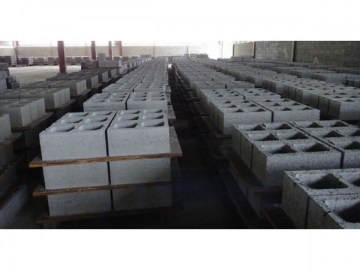

3. The entire molding process takes only a short time. It yields high quality blocks with a smooth, dense texture which meet accurate size requirements.

4. The block making machine is equipped with a secondary hopper which can add a layer of facing material to the top of compacted concrete. The resulting block is often a colored paver block topped with the face mix.

5. Specialized vibration isolator ensures all vibration forces act upon the mold which level out the concrete in it. The isolator also reduces noise level created by vibration.

6. The bodywork of this concrete block machine is an ultra-big, high-strength welded structure with great rigidity, vibration resistance, and long lifespan.

| Brick Specifications | Samples | pcs/mold | pcs/h | pcs/8h | 1 year (300 days) |

| Blocks 390×190×190mm 71pcs/m3 | 6 | 1080 | 8640 | 36507m3 | |

| Blocks 390×100×190mm 135pcs/m3 | 12 | 2160 | 17280 | 38400m3 | |

| Dutch Bricks 200×100×60mm 50pcs/m2 | 21 | 3780 | 30240 | 181440m2 | |

| Dog-Bone Bricks 200×165×60mm 30pcs/m2 | 12 | 2160 | 17280 | 171089m2 | |

| Zigzag Bricks 225×112.5×60mm 40pcs/m2 | 15 | 2700 | 21600 | 164051m2 | |

| Perforated Bricks 240x115x90 402pcs/m3 | 15 | 2700 | 21600 | 6.48 million pcs | |

| Solid Bricks 240x115x53 683pcs/m3 | 30 | 5400 | 43200 | 13 million pcs |

| Machine Dimension | 6500×3800×2600(mm) |

| Pallet Size | 850×680×20(PVC plate) |

| Weight | 8350kg |

| Vibration Frequency | 50-90Hz |

| Maximum Excitation Force | 70KN |

| Molding Cycle | 15-20S |

| Installed Capacity | 29.5KW |