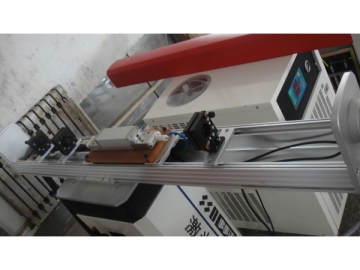

Laser Welding Machine

Laser Welding Machine VCT-180LW

- VCT-LW300D

- VCT-180LW

- VCT-200LW

Sometimes the laser welding machine is used to weld channel letters. Other times, the laser welder works on small items, including the likes of jewelry, handicraft, hardware, clock, and watch. Beyond that, military, electronic, and communications industries also find the laser welding machine a very handy tool.

Benefits of Laser Welding Machine

1. Brand-name laser welder parts are from Panasonic, Sony, etc.

2. German laser welding technology, maintenance free for a lifetime

3. Higher power laser is among the options.

4. Work non-stop for 24 hours

Features of Laser Welding Machine

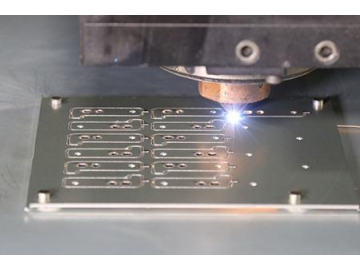

1. This laser welder is quite good at turning out highly detailed artwork – small, complex channel letters or logos that would be too complicated for other welding techniques. The result of laser welding is very stunning, with no color difference before and after welding, no traces of weld, and no need for further refinement.

2. There are no bumps appearing around the welded surface, which eliminates the need of polishing or grinding thereby saving processing time.

3. The laser welding process operates quietly and does not generate pollution.

4. 360-degree free rotation allows the laser to access difficult areas.

5. Upon your request, we can add a CCD monitor to your laser machine to ensure the welding process is under clear supervision.

Features of Laser Welding Machine

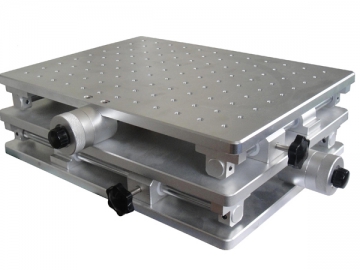

1. Lifting Table

Thanks to the lifting table, VICUT laser welder can make quick work of various kinds of stainless steel letters, luminous letters, titanium letters, copper letters, copper antique letters, metal paint words, etc. The result is a firmly welded structure with beautiful weld lines.

2. LED Floodlight

High-density laser beam and fast laser welding process cause little or no impact on parts that one doesn't want welded. The welded channel letters show no signs of deformation whatsoever.

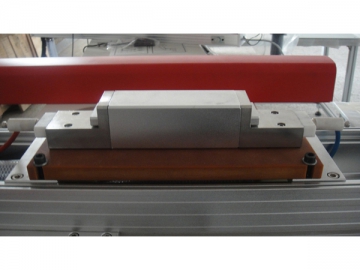

3. Laser Tube

Welding channel letters with laser is fast, easy, and clean. Because there is no direct physical contact with the letters being welded, parts wear won't occur. In the same it takes to weld a letter using other welding techniques, laser welding could probably do about 8 to 10 letters. This saves labor cost.

4. Control Panel

A small-size control panel all operators to easily control the laser machine. The laser creates very solid welding points and provides a very flexible way to weld.

5. Bodywork

In addition to welding AD letters, the laser welding machine is also widely used on a variety of small parts that require precision welding.

Technical Specifications

| Model | ||

| Laser type | Nd3 :YAG(with ceramic cavity) | |

| Energy of a single laser pulse | 120J | |

| Peak power | 6KW | |

| Laser wavelength | 1064mm | |

| Pulse xenon lamp | Φ8×270 | |

| Focus point diameter | Φ0.10-3.0mm(Adjustable) | |

| Rated output power | 180w/200w | |

| Minimum molten weld pool | 0.3mm | |

| Pulse width | 0.5ms-20ms(Adjustable) | |

| Pulse depth | 0.05-4mm | |

| Pulse frequency | 0-50Hz(Adjustable) | |

| Pulse system | Single-chip microcomputer control | |

| Water consumption | 15 L | |

| Circulating water resistance | >0.5MΩ-cm (De-ionized water) | |

| Continuous operating time | 720 Hours | |

| Monitoring System | CCD Display System | |

| Power supply | (Single) Ac220V 10%,(Three-phase) 380V±10% | |

| Weight | Around 180kg | |

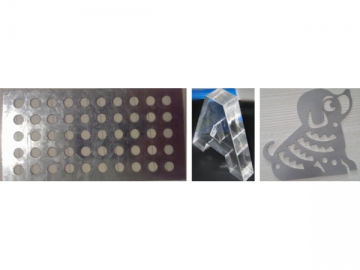

Laser Welded Samples