Press Brake Controller

Controller means essentially for the press brake. As a reliable supplier of press brake, we now provide rich press brake CNC systems to our customers, satisfying their different needs in applications.

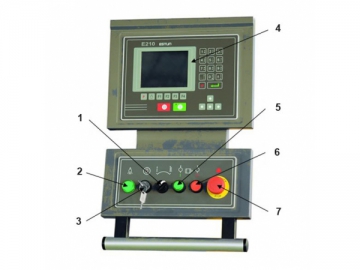

1. Key Switch for Main Power

2. Power Indicator

3. Jog, Semi-auto, Full-auto

4. E21System

5. Pump Start Button

6. Pump Stop Button

7. Emergency Stop

1. Especially applicable to: WD67Y CNC Press Brake

2. Features of E21 CNC Controller Made by China Estun

1) Control of back gauge and stop dog;

2) Control of common motor or variable frequency motor;

3) Intelligent positioning ;

4) Workpiece counting;

5) Dwell time setting;

6) Storage of 40 programs each of which contain at most 25 process steps;

7) One side positioning;

8) One-click specification backup and restore;

9) Retracting function;

10)mm/inch;

11) Display language: Chinese/English

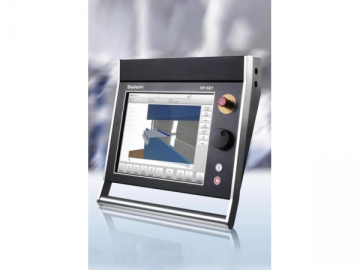

1. Especially applicable to: WF67K Electro-Hydraulic CNC Press Brake

2. Features of DA-56 CNC Control System

Of a laconic structure, this DA-56 CNC controller enjoys high cost performance and could provide you best controlling solutions for your bending machine.

1) Designed with 2D graphics design tools, this controller makes it easier for you to write new programs. The process step setting function could reduce the debugging and tests to the minimum.

2) With only one click, this controller could write a CNC controlling program automatically after it located the position of each axis and display the situation on the screen in a certain proportion and the size of the mould.

3) During the real operation, users could first simulate the entire processes with graphs on this DA-56 CNC system.

4)The basic configuration of this control system is Y1-Y2-X-R axes. Especially, the R axis could be used as the Z axis or X2 axis. The defection compensation device is of a standard configuration.

Features of DA-56 CNC Control System

1. 2D graphical programming;

2. electro-hydraulic control or twisted axis control;

3. 10.4 inch LCD TFT display;

4. LCD color display;

5. Bending processing steps setting;

6. 10" TFT true color display;

7. Developed length calculation;

8. 500 MHz processor;

9. Deflection compensation device for worktable;

10. Memory capacity:128 MB;

11. USB interface;

12. Memory capacity for mould information: 32 MB;

13. Panel installation method;

14. Mould library(30 upper dies and 60 lower dies);

15. servo control, frequency control and AC motor control;

16. USB storage;

17. Power down memorization;

1.Especailly applicable to: WF67K Electro-Hydraulic CNC Press Brake and 2-WF67K Tandem Press Brake

2. Features of DA-65W CNC Control System

1) The reliable inbuilt windows operation system this CNC control device adopts could ensure the system to operate smoothly during the startup and emergent stop.

2)This DA-65W controller enjoys a user-friendly operation interface, high-efficiency programming modes and excellent stability, significantly promoting the working efficiency of the press brake.

3)The graphical programming device of this CNC system enjoys the technological advantages of Delem and could display the workpiece, die and machine tool in true proportion.

4)The 2D graphical programming software of this CNC system enjoys several functions such as automatic bending-sequence calculation and workpiece inspection. Equipped with a database for self learning, this control device could promote the bending precision of the brake. Moreover, the 3D display could vividly show the machine tool and mould and simulate the bending operation.

5) The new control algorithm for Y-axis is more rational and could reduce the time spent in machine tool adjustment, optimizing the entire operation of the press brake and improving its working efficiency.

6.Through the windows system, this CNC controller could be connected with the factory's network and exchange data with any computer in this network.

Standard Configuration of DA-65W CNC Control System

1. 2D graphical programming;

2. Color LCD display;

3. 3D D graphical programming;

4. 10.4 inch High Brightness TFT LCD;

5. 10.4" color TFT LCD display;

6. 800×600, 16 colors;

7. Elements for Windows system;

8. 600MHz microprocessor;

9. integrated and individualized operation penal;

10. Memory capacity:128MB;

11. USB interfaces for mouse and keyboard;

12. 64MB Memory capacity for information about product and mould;

13. support for special applications under multi-tasking environment;

14. 3D graphics accelerator;

15. Angle sensor interface;

16. Windows network connection;

17. Emergent stop button;

18. USB flash memory drive;

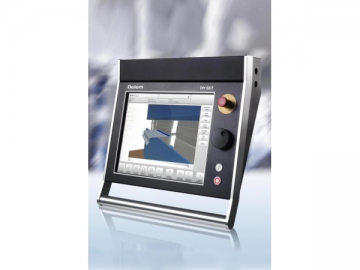

1. Especially applicable to: WF67K Electro-Hydraulic CNC Press Brake and 2-WF67K Tandem Press Brake

2. Features of DA-66T CNC Control System

1) 1) The reliable inbuilt windows operation system this CNC control device adopts could ensure the system to operate smoothly during the startup and emergent stop.

2) Designed based on the latest techniques, this new CNC system is equipped with an Infrared touch screen, quite easy to operate. More importantly, it could significantly promote the efficiency of programming and control.

3) The application programming interface of this controller provides more navigation quick keys for programming and machine tool setting, effectively reduce time spent in operating time.

4) The 2D graphical programming software of this CNC system enjoys several functions such as automatic bending-sequence calculation and collision detection. Moreover, the 3D display could vividly show the machine tool and mould and simulate the bending operation.

Standard Configuration of DA-66T CNC Control System

1. 2D touch screen graphical programming;

2. Color LCD display;

3. 3D graphical display for product simulation;

4. 17 inch High Brightness TFT LCD display;

5. 17-inch high resolution true color TFT LCD display;

6. 1280×1024,32 colors;

7. Windows Application Package;

8. Infrared touch screen;

9. Compatible with the Delem modular system;

10. Memory capacityL:1 GB;

11. USB interfaces;

12. 3D graphics accelerator;

13. support for special applications under multi-tasking environment;

14. 3D graphics accelerator;

15. Angle sensor interface;

16. Windows network connection;

17. Emergent stop button;

18. USB flash memory drive;

1. Key Switch for Main Power

2. Power Indicator

3. Jog, Semi-auto, Full-auto

4. E21System

5. Pump Start Button

6. Pump Stop Button

7. Emergency Stop

1. Especially applicable to: WF67K Electro-Hydraulic CNC Press Brake

2.Features of E210 CNC System Made by China Estun

1). 5.6" TFT color display;

2). Program memory: 100 programs and 25 steps per program(maximum);

3). Tool library:15 punches and 15 dies;

4). Conventional press brake control;

5). Angle programming and automatic bending position calculation;

6). Back gauge allowance compensation;

7). Dual servo system control;

8). Flexible I/O configuration;

9). Free group valve setting;

10). One side positioning;

11). Retract function;

12). Power-down memorization;

13). mm/Inch;

14). Display language: Chinese/English;

15). Diagnosis function.

1. Especially applicable to: WF67K Electro-Hydraulic CNC Press Brake

2. Features of Da-41 CNC System

This DA-41 CNC system is geared to the WD67K CNC torsion bar synchrony press brake. Adopting latest electrical technologies, this controller could provide a set of unique solutions to the flexible definition of sliding stroke, back gauge and output/input of the press brake. It provide multiple control methods, such as the servo motor control, two-speed AC motor control and frequency control and so on. Users could choose the double-side positioning or one side positioning according to the specific applications. The high-resolution LCD display makes the operation much easier. Users could write a program through typing angel, mould specifications and necessary information into the form which allows the full-screen edition.

Features of DA-41 CNC System

1. High resolution LCD display;

2. Control of the position where the sliding stroke stops;

3. Bending angle programming;

4. Mould parameters setting;

5. Memory Capacity: 100 programs and 25 processing steps at least;

6. Penal Type installation;

7. servo control, frequency control and two-speed AC control;

1. Especially applicable to: 2-WF67K Tandem Press Brake

2. Features of DA-52 CNC System

1) Flshing programming for specifications;

2) Navigation quick key;

3) 6.4 inch true color TFT LCD display;

4) Axis control(at most four axes, the Y1-axis, Y2-axis and another two additional axes);

5) Worktable defection table

6) Mould library/ material library and materials library;

7)USB interface;

8) The advanced Y-axis control algorithm enables this CNC system to control the closed loop or open loop;

9) Panel type installation(Suspension box is available as well);

Standard configuration of DA-52 CNC System

1. LCD color display;

2. 6.4" TFT,VGA LCD display;

3. 266MHz processor;

4. Memory capacity: 6.4MB;

5. Programs memory capacity: 2MB(minimum);

6. Mould library: 30 upper dies/ 30 lower dies;

7. USB storage;

8. Power-down memorization function.