Hydraulic Press Brake

The WD67Y press brake is for bending metal sheet and plate material, especially bending metal into different shapes. Nominal pressure of this series press brake is from 300KN to 6000KN. Made with advanced technologies, this press brake machine enjoys high working efficiency and accuracy, quite reliable for users. It has been applied for manufacturing industries such as aircraft, automobile, shipbuilding, electric equipment, machinery, kitchen ware and furniture, decoration and other light industries.

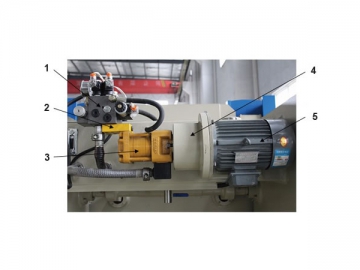

Components of Hydraulic Press Brake1. Hydraulic Valves Block

2. Stroke

3. Gear Pump

4. Flange type connecting seat

5. Please click

This structure comprises of the main motor, flanged connection seat, gear pump, hydraulic valves and block transition. The gear pump is driven by the main motor and the clearance error between them would be solved by the flanged connection seat. Meanwhile, the pump and hydraulic valves are connected by the block transition instead of pipes. Both detailed designs significantly promote the mechanical life of this gear pump.

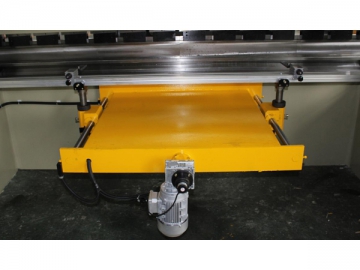

The back gauge of this sheet metal press brake is patent product developed by our company. The ball screws are directly driven by the X-axis turbine and guided by the linear guide rails at both sides. This special design effectively avoids the precision error caused by the sprocket-wheel and chain design.

Features of WD67Y Press Brake

1.All components of the rack are designed with the welded steel plate structure and have gone through both tempering treatment and hot vibration stress relief treatment. Therefore, this sheet metal bending brake enjoys high precision.

2. Such important components of this press brake as the machine body and slide stroke are strictly inspected and tested with the FEA software made by ANSYS, in which way the reliability of the machine is ensured.

3. The two hydraulic cylinders of this bending machine which are respectively mounted on the stand columns at both sides could directly drive the slide stroke. Moreover, forced by the torsion bar, the stroke together with the cylinders could work in a synchronous way and could endure a certain eccentric load.

4. As the machine body adopts an integral structure, this sheet metal brake is quite easy to transport and use. More importantly, this structure design could ensure the high precision of the entire machine.

5. The oil feeding amount, hydraulic synchronization and the mechanical synchronization are controlled by the variable displacement pump. The electric switches could ensure the high precision of the synchronization of the upper part and the upper and lower parts of this brake press.

6. This system could allow the sliding stroke to descend rapidly or slowly, return quickly and stop suddenly.

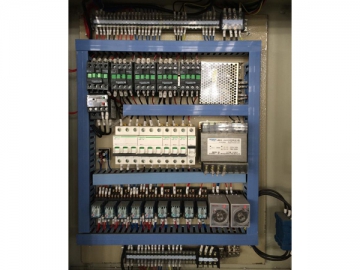

Control System of Press Brake1. Key Switch for Main Power

2. Power Indicator

3. Jog, Semi-auto, Full-auto

4. E21 System

5. Pump Start Button

6. Pump Stop Button

7. Emergency Stop

For detailed information about the system, please click the "" and visit the linked page.

Configuration of Press Brake

(1)The hydraulic system provided by Atos (Italy);

(2) Electrical systems provided by Schneider(France);

(3)Gear pump provided by Chengjie (devices provided by other foreign suppliers are also available for users, such as that provided by Sumitomo);

(4)main motor provided by Shuangta(China)( devices provided by other foreign suppliers are also available for users, such as that provided by Siemens);

(5) E21 system provided by Estum(China)( devices provided by other foreign suppliers are also available for users, such as that provided by ELGO)

(6)Ball Screw.

| Model | PN | Length of Table | Column Distance | Throat Depth | Stroke Length | Maximum Open Height | Main Motor Power | Dimensions |

| (KN) | (mm) | (mm) | (mm) | (mm) | (mm) | (kW) | L×W×H(mm) | |

| 300 | 1600 | 1250 | 170 | 90 | 195 | 3 | 1800×920×1660 | |

| 400 | 2500 | 2150 | 245 | 100 | 330 | 5.5 | 2700×1200×1950 | |

| 500 | 2500 | 2150 | 245 | 100 | 330 | 5.5 | 2700×1200×1950 | |

| 630 | 2500 | 2000 | 250 | 120 | 350 | 5.5 | 2700×1350×2120 | |

| 630 | 3200 | 2580 | 250 | 120 | 350 | 5.5 | 3400×1350×2120 | |

| 800 | 2500 | 2000 | 250 | 120 | 350 | 7.5 | 2700×1350×2120 | |

| 800 | 3200 | 2580 | 250 | 120 | 350 | 7.5 | 3400×1350×2120 | |

| 1000 | 2500 | 2000 | 300 | 130 | 400 | 7.5 | 2700×1465×2300 | |

| 1000 | 3200 | 2580 | 300 | 130 | 400 | 7.5 | 3400×1465×2300 | |

| 1000 | 4000 | 2980 | 300 | 130 | 400 | 7.5 | 4200×1465×2300 | |

| 1250 | 2500 | 2000 | 300 | 130 | 400 | 11 | 2700×1465×2300 | |

| 1250 | 3200 | 2580 | 300 | 130 | 400 | 11 | 3400×1465×2300 | |

| 1250 | 4000 | 2980 | 300 | 130 | 400 | 11 | 4200×1465×2300 | |

| 1600 | 3200 | 2580 | 340 | 150 | 450 | 11 | 3400×1620×2500 | |

| 1600 | 4000 | 2980 | 340 | 150 | 450 | 11 | 3400×1620×2500 | |

| 1600 | 5000 | 4000 | 340 | 150 | 450 | 11 | 5200×1620×2850 | |

| 1600 | 6000 | 5000 | 340 | 150 | 450 | 11 | 6200×1620×3000 | |

| 2000 | 3200 | 2580 | 340 | 150 | 450 | 15 | 3400×1620×2500 | |

| 2000 | 4000 | 2980 | 340 | 150 | 450 | 15 | 3400×1620×2500 | |

| 2000 | 5000 | 4000 | 340 | 150 | 450 | 15 | 5200×1620×2850 | |

| 2000 | 6000 | 5000 | 340 | 150 | 450 | 15 | 6200×1620×3000 | |

| 2500 | 3200 | 2580 | 400 | 200 | 500 | 18.5 | 3400×1700×2900 | |

| 2500 | 4000 | 2980 | 400 | 200 | 500 | 18.5 | 4200×1700×2900 | |

| 2500 | 5000 | 4000 | 400 | 200 | 500 | 18.5 | 5200×1700×3000 | |

| 2500 | 6000 | 5000 | 400 | 200 | 500 | 18.5 | 6200×1800×3200 | |

| 3000 | 3200 | 2580 | 400 | 200 | 520 | 22 | 3200×2000×3000 | |

| 3000 | 4000 | 2980 | 400 | 200 | 520 | 22 | 4200×2000×3000 | |

| 3000 | 5000 | 4000 | 400 | 200 | 520 | 22 | 5200×2000×3200 | |

| 3000 | 6000 | 5000 | 400 | 200 | 520 | 22 | 6200×2100×3400 | |

| 3500 | 3200 | 2580 | 400 | 250 | 570 | 22 | 3400×2000×3000 | |

| 3500 | 4000 | 2980 | 400 | 250 | 570 | 22 | 4200×2000×3000 | |

| 3500 | 5000 | 4000 | 400 | 250 | 570 | 22 | 5200×2000×3200 | |

| 3500 | 6000 | 5000 | 400 | 250 | 570 | 22 | 6200×2100×3400 | |

| 4000 | 3200 | 2580 | 400 | 250 | 580 | 22 | 3400×2000×3100 | |

| 4000 | 4000 | 2980 | 400 | 250 | 580 | 22 | 4200×2000×3100 | |

| 4000 | 5000 | 4000 | 400 | 250 | 580 | 22 | 5200×2000×3300 | |

| 4000 | 6000 | 5000 | 400 | 250 | 580 | 22 | 6200×2100×3500 | |

| 5000 | 4000 | 3000 | 500 | 300 | 640 | 37 | 4200×2300×3600 | |

| 5000 | 5000 | 4000 | 500 | 300 | 640 | 37 | 5200×2450×4000 | |

| 5000 | 6000 | 5000 | 500 | 300 | 640 | 37 | 6200×2450×4200 | |

| 6000 | 4000 | 3000 | 500 | 300 | 660 | 45 | 4200×2300×3600 | |

| 6000 | 5000 | 4000 | 500 | 300 | 660 | 45 | 5200×2450×4000 | |

| 6000 | 6000 | 5000 | 500 | 300 | 660 | 45 | 6200×2450×4200 |