CNC Hydraulic Guillotine Shear

This QC11k CNC hydraulic guillotine shear is for shearing sheet metal with thickness from 4mm to 40mm, shearing width from 2500mm to 6000mm. This sheet metal shear is equipped with a specially designed servo CNC system which could adopt three types of controls, namely, the single-axis control function, double-axis control function and triple-axis control function. Therefore, users could choose a control type according to their needs. If required, we could provide a customized retainer which could significantly promotes the bending precision.

Main Features of Hydraulic Guillotine Shearing Machine

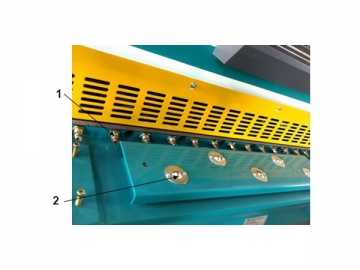

1. This CNC guillotine shearing machine adopts an integrated welded rack and has gone through the stress relief treatment. That is why this shearing machine tool enjoys great mechanical rigidity and high operation precision.

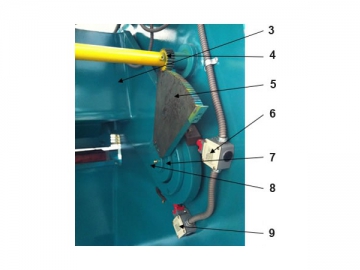

2. The back gauge of this hydraulic guillotine shear is constructed by imported screw balls and linear guide ways. Driven by the servo motor, it could help ensure the high precision of the operation.

3. Equipped with quality valves provided by Rexroth(German), electrical elements provided by Schneider(France) and high performance gear pump, this sheet metal cutter enjoys quite reliable performance.

4. The movable blade bearing and four-edge long blades make it convenient for users to adjust the clearance between each blade in an even way. This design could not only expand the service life of the blades but also promotes the cutting precision.

5. Motorized back gauge device and the electrical counter make it easier for users to adjust the position of back gauge.

6. As this sheet metal shear is equipped with ball bearing retainer and retainer bar, it is quite easy for suers to operate the machine.

7. This CNC hydraulic guillotine shear adopts a front gauge which, attached with a steel ruler is perpendicular to the lower blade.

8. There are there control types available for users.

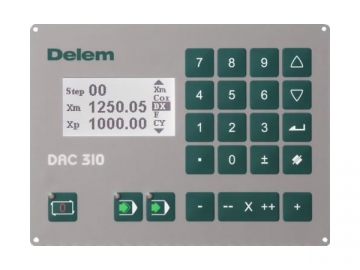

Control System of CNC Hydraulic Guillotine Shear

1. This hydraulic sheet metal shearing machine adopts the DAC-310 CNC system which, manufactured with the latest electrical technologies, enjoys a laconic structure, multiple functions and reliable performance. This controller could provide a set of unique solutions to control of back gauge, blade gap and shearing process.

2. The control of back gauge could adopt such axis controls as servo motor control, two-sped AC motor control and frequency control.

3. As for the positioning of back gauge, users could choose the double-side positioning or the single side positioning which could effectively eliminate the clearance between ball screws.

4. Back gauge's reference point could be set automatically as the machine gets started.

5. The back gauge could be moved manually at two speeds after the “move” key is pressed.

6. The high resolution LCD display makes the programming much quicker and easier.

7. The real positional value of the back gauge and the value in programming will be displayed at the same time. Moreover, the selection function of the process counter could be displayed.

8. Settings such as the process step linking and repeat counting are available for each process step.

Main Functions and Configuration of DAC-310 CNC System

128×64 LCD display ;

Back gauge control

Membrane keypad made of high quality metal domes;

Blade gap control;

panel type installation;

Cutting stroke control;

synchronous display of the back gauge's real positional value and that in the programming;

Cutting counter;

100 programs;

Servo motor control/ frequency control/ two-speed AC motor Control.

A Complete Solution for Hydraulic Sheet Metal Shearing Machine

1. This DAC-360 CNC control system, a leading product designed with the latest electrical technologies, provides a complete solution to the control of the sheet metal forming machine which includes back gauge control, shear angle control, shearing stroke control, blade gap control and shear stress control.

2. This controller could automatically calculate the shear angle and blade gap according to the thickness and properties of plates to be sheared, and the shearing stroke according to the width of the plates. Therefore, it could help enormously reduce the cutting time.

3. There are three control methods available for the back gauge control of thissheet metal shearing equipment, namely the servo motor control, two-speed motor control and unipolar output mode with direction control. Additionally, users could choose the single/double-side positioning function which is attached with an axis deviation correction table.

4. This CNC system could control the clamping pressure and shearing pressure thought out the operation.

5. The high brightness LCD display provides a clear programming interface and makes the controller more user-friendly.

Standard Configuration of DAC-360 CNC System

Panel Type installation ;

4.7” Monochrome LCD Display;

High Brightness LCD Display;

Metal membrane switch;

Back Gauge Control

Memory Capacity: 100 programs and 25 Processing Steps Per Program(maximum);

Retracting Function;

Shear Angle Control;

Blade Gap Control;

Manual Positional Adjustment of All Axes;

Shearing Pressure Control.

Features of DAC-360 CNC System

This DAC-360 CNC system is designed based on the classic products in the international market. Therefore, it shares many advantageous properties with those excellent counterparts. Moreover, we have designed it in consideration of the domestic market's requirements for the sheet metal shearing tool in hope of promoting the production of sheet metal in China. Adoptingan unique drive control technique, this automatic controller could not only promotes the shearing precision but also reduce the operation cost. Given this, it has laid a foundation for the wide application of CNC guillotine shears in China.

This CNC controller enjoys the following control functions geared to the shearing machine

1. Positioning control of back gauge;

2. Single-side or double-side positioning, effectively eliminate gap between screw balls.

3. Retracting function.

4. Automatic setting of reference point.

5. Power-down memorization and protection of specification, position and processes.

6. Instruction function.

7. Memory capacity: 40 programs and 25 processing steps for each.

8. Manual operation(before the specification being set).

9. Two control method for back gauge control: servo motor control or frequency control.

10. F function.

11. Shearing stroke control.

Related Configuration of CNC Hydraulic Guillotine Shear

Hydraulic system provided by Rexroth in Germany;

Electrical system provided by Schneider Electric in France;

Gear pump provided by Chengjie (China)(devices provided by other foreign suppliers are also available for users, such as that provided by Sumitomo);

main motor provided by Shuangta(China)( devices provided by other foreign suppliers are also available for users, such as that provided by Siemens);

DAC360 CNC system provided by DELEM (Netherlands);

Screw balls and linear guideways provided by Taiwan suppliers.

| Model | Thickness of sheet metal | Width of sheet metal | Number of strokes | Back gauge range | Shear angle | Throat depth | Power of main motor | Dimension |

| (mm) | (mm) | (per/min) | (mm) | (。) | (mm) | (kW) | L×W×H(mm) | |

| 4 | 2500 | ≥18 | 600 | 0.5-2.5 | 100 | 5.5 | 3130×1500×2070 | |

| 4 | 3200 | ≥16 | 600 | 0.5-2.5 | 100 | 7.5 | 3830×1600×2170 | |

| 4 | 4000 | ≥12 | 600 | 0.5-2.5 | 100 | 7.5 | 4630×1600×2170 | |

| 6 | 2500 | ≥15 | 600 | 0.5-2.5 | 100 | 7.5 | 3150×1600×2170 | |

| 6 | 3200 | ≥13 | 600 | 0.5-2.5 | 100 | 7.5 | 3850×1600×2170 | |

| 6 | 4000 | ≥10 | 600 | 0.5-2.5 | 100 | 7.5 | 4650×1600×2170 | |

| 6 | 6000 | ≥6 | 600 | 0.5-2.5 | 100 | 11 | 6650×1610×2380 | |

| 8 | 2500 | ≥14 | 600 | 0.5-2.5 | 100 | 11 | 3170×1600×2170 | |

| 8 | 3200 | ≥12 | 600 | 0.5-2.5 | 100 | 11 | 3870×1600×2170 | |

| 8 | 4000 | ≥10 | 600 | 0.5-2.5 | 100 | 11 | 4670×1600×2170 | |

| 8 | 6000 | ≥6 | 600 | 0.5-2.5 | 100 | 15 | 6670×1610×2380 | |

| 10 | 2500 | ≥12 | 600 | 0.5-2.5 | 100 | 11 | 3190×1600×2170 | |

| 10 | 3200 | ≥10 | 600 | 0.5-2.5 | 100 | 11 | 3890×1600×2170 | |

| 10 | 4000 | ≥8 | 600 | 0.5-2.5 | 100 | 11 | 4690×1600×2170 | |

| 10 | 6000 | ≥5 | 600 | 0.5-2.5 | 100 | 15 | 6690×1610×2380 | |

| 12 | 2500 | ≥10 | 800 | 0.5-2.5 | 100 | 15 | 3270×1850×2315 | |

| 12 | 3200 | ≥8 | 800 | 0.5-2.5 | 100 | 15 | 3970×1850×2315 | |

| 12 | 4000 | ≥6 | 800 | 0.5-2.5 | 100 | 18.5 | 4770×1850×2315 | |

| 12 | 6000 | ≥4 | 800 | 0.5-2.5 | 100 | 22 | 7080×2310×3030 | |

| 16 | 2500 | ≥8 | 800 | 0.5-2.5 | 100 | 18.5 | 3270×1850×2315 | |

| 16 | 3200 | ≥7 | 800 | 0.5-2.5 | 100 | 18.5 | 3970×1850×2315 | |

| 16 | 4000 | ≥6 | 800 | 0.5-2.5 | 100 | 22 | 4770×1850×2315 | |

| 16 | 6000 | ≥4 | 800 | 0.5-2.5 | 100 | 30 | 7100×2310×3030 | |

| 20 | 2500 | ≥7 | 800 | 0.5-2.5 | 100 | 30 | 3370×2015×2575 | |

| 20 | 3200 | ≥6 | 800 | 0.5-2.5 | 100 | 37 | 4070×2015×2575 | |

| 20 | 4000 | ≥5 | 800 | 0.5-2.5 | 100 | 37 | 4870×2015×2675 | |

| 20 | 6000 | ≥3 | 800 | 0.5-2.5 | 100 | 45 | 7220×2450×2990 | |

| 25 | 2500 | ≥6 | 1000 | 0.5-3 | 120 | 37 | 3480×2105×2690 | |

| 25 | 3200 | ≥5 | 1000 | 0.5-3 | 120 | 37 | 4180×2105×2690 | |

| 25 | 4000 | ≥4 | 1000 | 0.5-3 | 120 | 45 | 4980×2105×2790 | |

| 25 | 6000 | ≥3 | 1000 | 0.5-3 | 120 | 55 | 7240×2450×2990 | |

| 32 | 2500 | ≥6 | 1000 | 0.5-3 | 120 | 37 | 3490×2440×2915 | |

| 32 | 3200 | ≥5 | 1000 | 0.5-3 | 120 | 45 | 4190×2440×2915 | |

| 32 | 4000 | ≥4 | 1000 | 0.5-3 | 120 | 45 | 4990×2440×3015 | |

| 32 | 6000 | ≥3 | 1000 | 0.5-3 | 120 | 55 | 7240×2685×3470 | |

| 40 | 2500 | ≥4 | 1000 | 0.5-3 | 120 | 75 | 3530×2500×3300 | |

| 40 | 3200 | ≥3 | 1000 | 0.5-3 | 120 | 75 | 4230×2500×3500 |

The above parameters are subject to change without notice.