Mechanical Swing Beam Shear

To satisfy customers’ needs for mechanical sheet metal shearing machine, we have developed this Q11 mechanical shearing machine which, adopting a steel-structured rack and laconic design, enjoys excellent mechanical strength, reliable performance, easy maintenance and long service life. Now, there are two models for selection, namely, the mechanical swing beam shear and mechanical guillotine shear, both of which enjoy advantageous features. For more information about this cutting machine, please visit the linked pages or feel free to contact us.

Mechanical Swing Beam Shear

This mechanical swing beam shear has high precision in shearing sheet metal. It is suitable for different metal materials. It is used for shearing sheet metal with thickness from 3mm to 12mm, and width from 1300mm to 4000mm. This shearing machine is widely applied in manufacturing industries for aircraft, automobile, furniture and house decoration.

Main Features of Swing Beam Shearing Machine

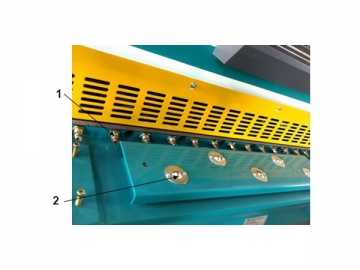

This Q11A mechanical swing beam shear gains customers’ trusts for its excellent functions and reliable performances. Adopting a welded steel rack and a laconic structure, this mechanical cutting machine enjoys high mechanical strength and rigidity. It adopts the hydraulic transmission and has gone through the vibratory stress relief treatment. With the help of its cylinder mounted on the wallboard this swing beam shear could descend to cut the metal sheet and then return with the assistance of nitrogen cylinder. That is why it could operate in that stable way.

To be more specific, the upper blade carrier of this metalworking shear swings around a certain axis during the shearing operation. The leverage ensures the fulcrum to bear much smaller force. Thus, the blades as well as this shearing machine tool enjoy a longer service life. At the same time, the processing stroke of the carrier could be adjusted freely and the working efficiency of the shearing machine is significantly promoted.

Applications of Mechanical Swing Beam Shear

This mechanical swing beam shear, geared to the fabrication of metal plates, is a reliable sheet metal forming equipment enjoying high operation efficiency and precision. It could significantly promote the metal working fabrication. Thanks to its advantageous properties, this swing beam shear has been considered an ideal sheet metal cutter and applied in a wide range of areas such as the aircraft manufacture, auto manufacture, shipbuilding, electrical industry, mechanical machinery manufacture, decoration, furniture production and so on.

| Model | Thickness of sheet metal | Width of sheet metal | Number of stroke | Back gauge range | Shear angle | Throat depth | Power of main motor | Dimension |

| (mm) | (mm) | (per min) | (mm) | (。) | (mm) | (kW) | L×W×H(mm) | |

| 3 | 1300 | 40 | 600 | 2° | 100 | 5.5 | 3130×1500×2070 | |

| 3 | 1600 | 40 | 600 | 2° | 100 | 7.5 | 3830×1600×2170 | |

| 4 | 1300 | 22 | 600 | 2° | 100 | 7.5 | 4630×1600×2170 | |

| 4 | 1600 | 22 | 600 | 2° | 100 | 7.5 | 3150×1600×2170 | |

| 4 | 2000 | 22 | 600 | 2° | 100 | 7.5 | 3850×1600×2170 | |

| 4 | 2500 | 22 | 600 | 2° | 100 | 7.5 | 4650×1600×2170 | |

| 4 | 3200 | 22 | 600 | 1°30' | 100 | 11 | 6650×1610×2380 | |

| 4 | 4000 | 19 | 600 | 1°35' | 100 | 11 | 3170×1600×2170 | |

| 6 | 1500 | 22 | 600 | 2° | 100 | 11 | 4670×1600×2170 | |

| 6 | 2500 | 19 | 600 | 2° | 100 | 15 | 6670×1610×2380 | |

| 8 | 2000 | 19 | 600 | 2° | 100 | 11 | 3890×1600×2170 | |

| 8 | 2500 | 19 | 600 | 2° | 100 | 11 | 4690×1600×2170 | |

| 12 | 2000 | 11 | 600 | 2°30' | 100 | 15 | 6690×1610×2380 |

Please not that: the above parameters are subject to change without notice.

Mechanical Guillotine Shear

This small-sized mechanical guillotine shear is for shearing thin sheet metal with thickness from 2mm to 3.5mm, and width from 1250mm to 3660mm.

Features of Mechanical Guillotine Shear

This Q11D mechanical guillotine shear we provide to you is an optimized version of the traditional mechanical guillotine shear and has been admittedly considered the most advanced small-sized shearing machine around the world. It is distinct from its counterparts for its high operation efficiency, energy efficiency and environment friendliness.

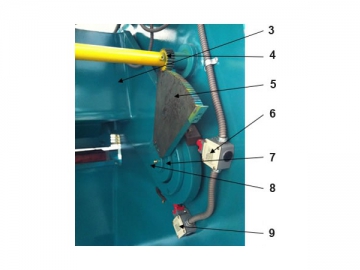

Designed with the advanced technologies both at home and abroad, this mechanical sheet metal cutter adopts an electro-mechanical disc brake whose axis, attached with a speed reducer, is driven by the motor and controlled by a pedal switch. As the shearing angle of this metalworking shear is much smaller and the shear direction is inclined, the sheet metal plate will have a minimum deformation during the shearing operation. The blade gap could be adjusted manually in a swift and easy way.

Technical Parameters of Guillotine Shear| Model | Maximum thickness of sheet metal | Maximum width of sheet metal | Processing stroke number | Back gauge range | Shearing angle | Power of master motor | Height of worktable |

| (m) | (mm) | (Per min) | (mm) | (。) | (kW) | (mm) | |

| 2.5 | 2500 | 47 | 0-650 | 1° | 5.5 | 800 | |

| 3.2 | 2000 | 47 | 0-650 | 1°45' | 7.5 | 800 | |

| 3.2 | 2500 | 47 | 0-650 | 1°18' | 7.5 | 800 | |

| 3.5 | 1250 | 47 | 0-650 | 1°30' | 5.5 | 800 | |

| 3.5 | 1300 | 47 | 0-650 | 1°30' | 5.5 | 800 | |

| 3.5 | 1500 | 47 | 0-650 | 1°30' | 5.5 | 800 | |

| 3.5 | 1600 | 47 | 0-650 | 1°30' | 5.5 | 800 | |

| 3.5 | 1800 | 47 | 0-650 | 1°30' | 5.5 | 800 | |

| 2 | 3660 | 47 | 0-650 | 1°30' | 11 | 800 | |

| 3 | 3050 | 47 | 0-650 | 1°30' | 11 | 800 |

Please note that

The above parameters are subject to change without notice.

The E10 digital display for the motorized back gauge could be provided to customers if required.