Machine Knives and Blades(Straight Knife and Slitting Blade for Cutting Plastic)

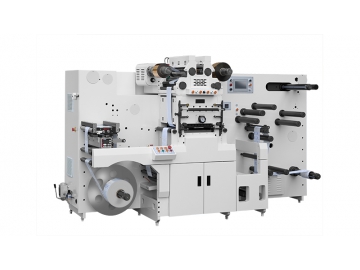

The plastics industry is one of our important businesses so we offer machine knives and blades in a wide range of materials, thicknesses, and geometries to suit them for use on pelletizer, polyethylene cutter, or punching machine. If you are involved in any plastics businesses that require plastics cutting, drilling, notching or shearing and you are looking for a tailor-made straight knife and slitting blade, please rest free that HENGLIDA can handle your OEM cutting blade projects large or small.

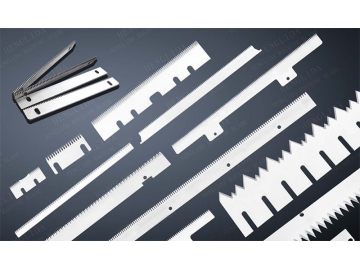

HENGLIDA plastic cutting blade is currently available in two versions: roll slitter blade for slitting plastic films and plastic granulator blade or plastic shredder blade for cutting plastics into flakes or even smaller sizes. Roll slitter blades can be subdivided into straight blades and circular blades while plastic granulator blades or plastic shredder blades need to be made of high-quality tool steel to withstand excessive wear and tear.

HENGLIDA holds tight tolerances for the geometries and sizes of the machine knife and blade to ensure a seamless fit with the machine to which it will be attached. Depending on the kind of plastic materials to be shredded or sheared, we will carefully select the right steel grade to handle your plastic shredding tasks. Multiple smart machining practices ensure the blade gets the perfect edge angle which not only maintains the sharpness but also allows the blade to have a certain level of toughness to resist breakage during high-speed shearing. Each blade is properly heat treated to maintain a balance between the hardness and internal stress of the blade.

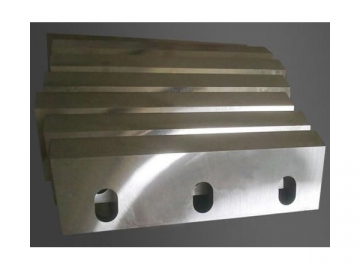

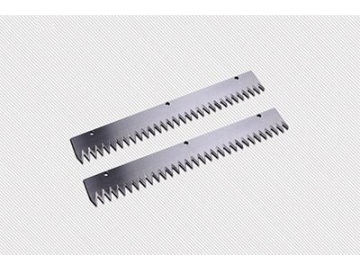

Features of HENGLIDA Plastic Granulator Blade or Plastic Shredder Blade

1. Suited for cutting ABS, PE, and PP plastic sheets into flakes or smaller sizes

2. The complete set of plastic granulator blades includes the fixed blade, helical screw and claw blade. The helical screw and claw blade spin at a fast speed to cut plastic products into granules.

3. Powerful combination blades require more complex manufacturing process than ordinary straight blades, which suit them for most plastics cutting applications such as shredding plastic sheets, pipes, profiles, and packaging.

4. Available in either full steel or inlaid steel, the powerful blade combination maintains a hardness level of between HRC55 and HRC58, and is resistant to impact, wear and high temperature.

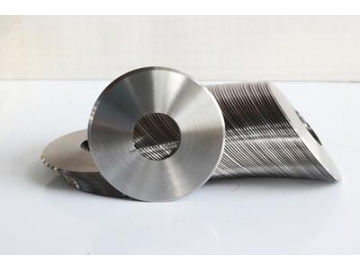

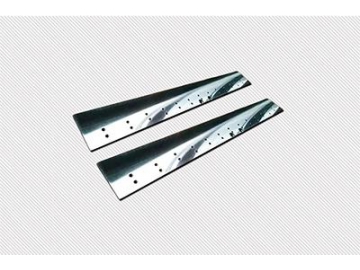

Features of HENGLIDA Strand Pelletizer Blade

Please note that many may confuse the strand pelletizer with the plastic granulator, particularly in China. The essential difference between the two machines is that a pelletizer cuts melted plastics coming out from the extruder die while a plastic granulator shreds real plastic bottles, sheets, pipes and more into flakes or granules.

1. The fixed knife is a straight blade which is easy to manufacture.

2. Rotating circular knives cut polymer melts coming out from the extruder die into pellets. Note that the melts are often in the form of spaghetti-like strands. HENGLIDA strand pelletizer blade is very popular in strand pelletizing industry.

3. Hardness: HRC58-62

4. Mechanical properties: resistance to impact, wear and high temperature

5. Suitable for cutting melted PE, PP, PVC, PS, ABS, AS and HIPS.