CPVC Resin

1. General Description

Chinese name: CPVC Resin

English name: chlorinated polyvinyl chloride

CAS No.: 68648-82-8

EINECS No.: -

Made from polyvinyl chloride (PVC) resin by chlorinated modification, the CPVC resin is a new type of engineering plastics. The product appears in forms of loose particles or powder in white or pale yellow color, tasteless, odorless, and non-toxic.

The chlorinated PVC resin, namely the CPVC resin, has increased molecular bond irregularity and polarity, as well as increased solubility and chemical stability. So it can better withstand heat and resist corrosions of acid, alkali, salts, oxidizing agents, etc. The chlorination also improves the thermal deformation mechanical properties of the resin:

a) chlorine content from 56.7% to 63-69%;

b) Vicat softening temperature from 72-82 ℃ to 90-125 ℃;

c) maximum service temperature up to 110 ℃;

d) long-term service temperature is 95 ℃.

Therefore, CPVC resin is a promising type of new engineering plastic.

2. Our Advantages

The CPVC resin is made by aqueous suspension (slurry) chlorination. In the process, replacement reaction takes place between the dedicated PVC resin and chloride ions under proper conditions. Its molecular structure is: -CHCl-CHCl-CH2-CHCl-.

Because of the chlorine content increases, the CPVC resin is more irregular in molecular structure (decreased crystallinity, enhanced molecular chain polarity). As a result, its thermal deformation temperature is higher than that of the PVC resin. The CPVC resin can normally serve at temperature as highest as 95-110 ℃, which is 30-40 ℃ higher than the PVC resin. Meanwhile, it can better resist acid, alkali, salt, fatty acid salts, oxidants, halogens and other chemical corrosions. In addition, compared with PVC, CPVC has improved tensile strength and flexural strength. Compared with other polymer materials, CPVC is more excellent in resisting aging and corrosion and superior in flame retardancy as well.

CPVC Resin Features

a) wide service temperature - theVicat softening point is increased by about 40 ℃. TheCPVC hardware is available for long-term use in a range of 40 ℃ ~ 98 ℃. So the resin is one of the few polymers that can be possibly used for long term at high temperatures and pressures.

b) good mechanical properties - the tensile strength of CPVC resin is 50% higher than PVC resin, and doubles those of ABS resin and PP resin. Especially near 100 ℃, CPVC resin can maintain a strong rigidity, which allows equipment and pipes to work under the temperature.

c) chemical resistance - CPVC not only showsexcellent chemical resistance at room temperature, but maintains the capability at higher temperatures. Its resistance to acid, alkali and other chemicals is far better than PVC and other resins, so it can replace traditional materials to handle corrosive substances.

d) fire retardance - CPVC resin has excellent self-extinguishing ability, with limiting oxygen index of 60. It limits flame spread and smoke generation, and there is no dripping in the fire.

e) low thermal conductivity - the thermal conductivity of CPVC resin is only 0.105KW / (mk). CPVC heat pipes have little heat loss, so it is not necessary to have an insulation layer.

f) immune to residual chlorine in water - polyolefin materials (such as PP, PE) may break when encounter residual chlorine in water, but CPVC will not be affected by the chlorine in water and will not crack and drip.

g) no bacteria breeding - since CPVC pipe can remain uninfluenced when being together with residual chlorine in water, its wall is smooth and hostile for the breeding of bacteria. The CPVC resin not only resists the erosion of all germs, but also resists the corrosion of general disinfection chemicals.

h) just like processing PVC - CPVC can be processed into various products in the same way as processing PVC, which is very simple and convenient.

i) easy installation - CPVC connection method is very similar to that of PVC. The most common and easiest method is solvent bonding. Other connection methods include threaded connections, flange connections and electrode connections.

j) no oxygen corrosion - CPVC resin is antioxidant itself, so the heat sink is free from the metal corrosion caused by oxygen penetration.

k) reduced additive penetration - in order to prevent oxidation, some modified plastic require a lot of antioxidants, which may penetrate into the water supply system and give off unpleasant odor.

l) low thermal expansion - thermal expansion coefficient of CPVC resin is lower than other plastics, and the material expands very slightly when filled with heat. In comparison, other types of pipes (such as PP-RRP) that has higher coefficient of expansion will be zig-zaged at high temperature, which is not safe or good-looking.

m) excellent durability - there is no such thermoplastic material as durable as CPVC resin, which can stand the test of hot water system for four decades without maintenance, showingits superiority performance.

3. Properties| Item | Model | |

| Chlorine content, % | 67 – 69 | 65 – 67 |

| Appearance | white powder | white powder |

| 30 mesh sieve rate, % | ≥ 99.0 | ≥ 99.0 |

| Volatile content, % | ≤ 0.35 | ≤ 0.35 |

| Thermal decomposition temperature, ℃ | ≥110 | ≥ 110 |

| Density (g/cm3) | 1.45-1.58 | 1.45-1.58 |

4. Packaging

The CPVC resin can be packaged in the following ways:

a) 25Kg / polywoven bag or kraft paper bag

b) 700Kg / flexible container

5. Usage

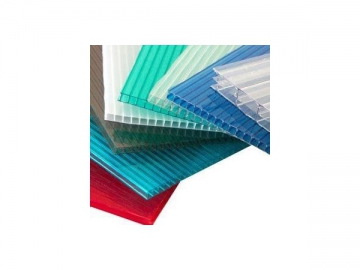

a) plate: plate, wave board, corrugated board, chemical equipment, etc.

b) CPVC tubing sheath for buried HV, EHV power transmission cable. Buried power cable

c) hot and cold water pipes and pipe fittings

Pipes and pipe fittings

d) material for places with strict firefighting requirements

e) crude oil gathering and transportation pipe

f) a plastic modifier: used on other thermoplastic and thermosetting engineering plastics, in order to improve their heat resistant, flame retardant properties

g) a foaming material: the material used for insulation of hot water pipes and steam pipes. Compared with PVC foaming materials, the CPVC ones are superior in heat resistance.Shrinkage of CPVC resin at high temperatures is relatively small, so it is ideal as a hot water pipe and steam pipe insulation material. If CPVC is placed into the solvent that produces gas when heated, it will facilitate the acquirement of uniform,microporous foaming gas. Hydrocarbons, ethers, aldehydes and other solvents that have boiling points within 50-160 ℃ can be chosen as the blowing agent.

h) by injection, extrusion, rolling and pressing methods,CPVC / PVC alloy can be made into molded pieces, trays, fan covers, electrical parts and housings, commercial machine casings, tubing, communication equipment and automotive parts.

i) used for making man-made fibers. CPVC thread can be made into fishing nets, uniforms, industrial filter fabrics, incombustible parachutes and submarine cable jackets.

j) by improving the production process, the produced CPVC may be better at impact resistance and transparency. This transparent material can be used on cars, compact discs, audio and video products.

6. Storage and Handling

a) The CPVC resin should be stored in dry and ventilated warehouse.

b) The stacking height should be not more than 10 bags.

c) Avoid sunlight and moisture.

d) Transportation must be done with clean and covered tools, to prevent the sun, rain and heat.

7. Safety

Safety identity

This product is non-dangerous.

QIANGYUAN is one of the most outstanding chemical manufacturers in China. Our products are targeted at many different fields, and welcome to work with us.