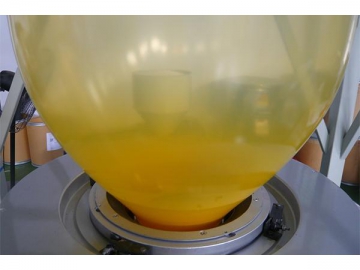

Rust Preventive Oil (Water Displacing Oil)

Model Selection for the Rust Preventive Oil

SF/Y 307, SF/Y 307HFB, SF/Y 307A

Specifications

190L/pail, 18L/pail

Rust Preventive Oil for Multimetals

As a popular selection of water displacing oil, the rust preventative oil is widely used to protect iron, steel, copper, and copper alloy.

| Model No. | Features, Uses |

| SF/Y 307 (for in-plant or cross plant processing) | Water-displacing rust preventive oil displaces water and saline solutions to keep corrosion from forming on metal parts in process or storage. Low-viscosity, thin oil film does not interfere with checking the dimensions of the work-piece being worked. Metal pieces don’t need to dry out to receive the corrosion prevention oil after they are washed with water in the first place. The protection lasts no less than 6 months. |

| SF/Y 307HFB (for preservation and lay-up of equipment) | Model 307HFB displaces only a certain amount of residual water and saline solutions remained on the metal pieces. This rust preventive oil, however, could provide proper rust protection that lasts up to 2 years. Users can dilute the rust prevention oil with kerosene to cut the duration of protection to a couple of months. |

| SF/Y 307A (for preservation and lay-up of equipment) | Exceptional water-displacing property allows the rust preventive oil to displace more water and saline solutions than other anti rust oil models can do. That is why metal parts needn’t drying after washing with water to receive the oil, as the rust preventive oil would drive out residual water. Low-viscosity, thin oil film envelops the cast iron, steel, copper and copper alloy, providing maximum rust protection that lasts 24 months on equipment stored indoors, 12 months if stored outdoors. Special VCI formulation offers higher resistance to heat, moisture, and salt spray than its contemporaries can provide. Dilute the water-replacing rust prevention oil 1:1 with kerosene to make a short-term rust prevention solution. |

Method of Use

Apply rust preventive oil by dip, brush, or spray to prevent rust on metal pieces in process. Take 4% to 8% of water-displacing rust preventative oil and add it to petroleum solvent. Mix the solution evenly to dilute the rust proofing oil. We suggest users select one of our VCI paper as the outer cover for metal parts being coated. Rust protection lasts up to 1 year.

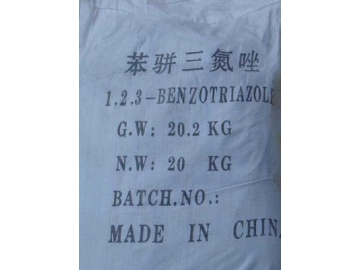

Storage

Keep the rust preventive oil tightly sealed in its original pail, drum or aerosol cans and away from water or other impurities. Keep the water displacing oil cool, dry, and out of direct sunlight, rain, or fire source.