VCI Powder (Water Based Anti Corrosion Powder)

Model Selection for the VCI Powder

SF/D-331

Specifications

3kg/pail, 20kg/pail

Water Based Anti Corrosion Powder for Ferrous Metals, Aluminum

The VCI powder is a water based anti-rust powder that comes in spray form. VCI spray offers corrosion protection for carbon steel, alloy steel, stainless steel, aluminum, and aluminum alloy.

VCI Powder Products

VCI powder spray is water soluble and present in the form of white spray powder. VCI powder ranges from 6.5 to 7.5 in pH value when dissolved in 1% water solution. Water solubility of VCI powder is 1g/2ml, measured at 25°C. Apply VCI powder by spray onto interior metal surfaces of enclosed spaces such as cavities or pipelines. Use wet or dry powder.

Applications of VCI Powder Spray

1. Interior metal surfaces of compressors, turbines, engines, storage tanks, boilers, and heat exchangers

2. Pipelines of steam condensers, closed loop heating and cooling systems

3. Internal cavities of equipment during hydrostatic testing and thereafter

4. Wet peening media

5. Cavities, gaps, holes, and cabinetry

Method of Use

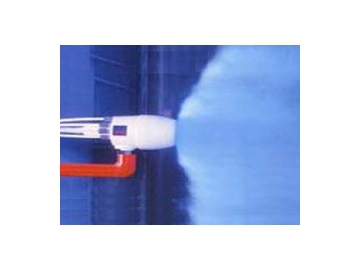

Dry Application

Apply VCI powders by sprinkling or fogging into pipelines or enclosed containers with an air hose, sand blasting gun, or large-scale sand blasting equipment. Under conditions of normal use, 100g VCI powder can protect 1 cubic meters of enclosed space. In adverse environments or the event of poor sealing, more VCI powder should be put to use.

Wet Application

Protect equipment during hydrostatic testing. After the test, remove the VCI water solution and seal the equipment. Dissolve the VCI powder in water and apply the solution to work-piece by dip, brush, or spray. After wet application, seal the metal pieces with packaging. Under conditions of normal use, the VCI water solution should contain 0.5% VCI concentration. Increase the concentration as environments grow worse. To further improve the wetness of metal surfaces, use our SF/TD-101 impregnating agent. Dosage of SF/TD-101 should be 1% of SF/D-331.

Method of Removal

Use compressed air to blow away or water to cleanse the remaining VCI powder on the metal surface. If wet application technique was initially used, no removing would be needed or simply cleanse it with running water or water spray.

Storage

Keep VCI powder spray in a cool, drifty room, and tightly sealed in its original package. Shelf life for VCI powder products is one year, starting from the date of manufacture.