VCI Foam (EPE Foam with Volatile Corrosion Inhibitor )

Model Selection for the VCI Foam

SF/DE-45EO—with both sides evaporating VCI

SF/DE-**EA—with only one side evaporating VCI, laminated with PE film

Specifications

Maximum width: 1000mm

Thickness: (1.5±0.5)mm

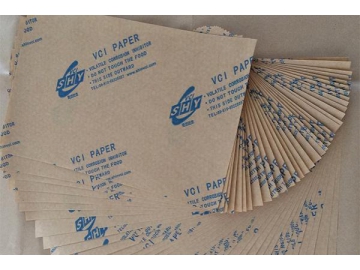

Anti Corrosion Packaging for Metals

The VCI foam is a great rust prevention packaging material for various metals, and also it can serve as a cushion material. If you need foam packaging material for corrosion protection and cushioning purposes for copper, steel, aluminum, and metal plating, then the EPE foam with volatile corrosion inhibitor is your best choice.

Standard Color

Blue

EPE Foam Products

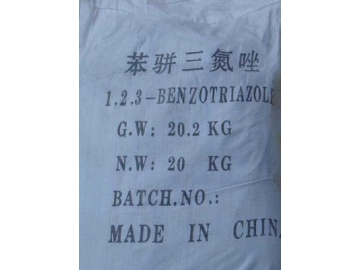

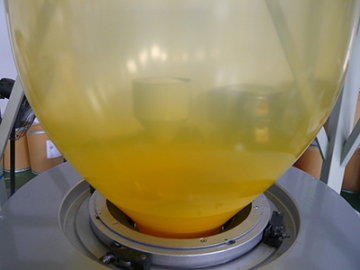

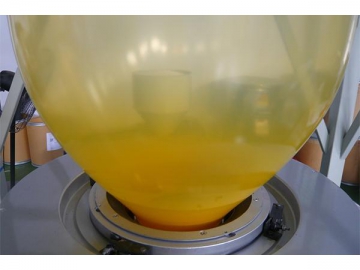

EPE foam is one of our proprietary VCI foam products. Expanded polyethylene foam is made of low-density PE mixed with special VCI formulations through a process known as foaming. The VCI foam provides a cushion to electronic components, precision parts, and metal pieces with sharp edges against shock, vibration and wear. Better yet, VCI technology adds a rust preventative layer to steel, copper, aluminum or metal plating being packed. Expanded PE foam can be coated with PE film to produce a rust-preventative laminate.

Applications of the VCI Foam

VCI EPE foam can be used as buffering, cushioning or filling materials for electronic devices, instruments, and precision parts. PE coated EPE foam can be used directly as the outer cover for large and bulky equipment including the likes of rollers, bearings, and military machinery.

Package

We sell VCI foam in rolls or sheets packed in a variety of ways.

Storage

Please keep VCI expanded polyethylene foam dry, out of direct sunlight, and away from acidic, alkaline or salty conditions. The shelf life of VCI foam is 12 months.