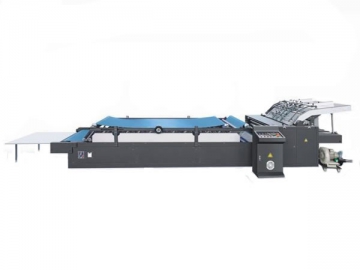

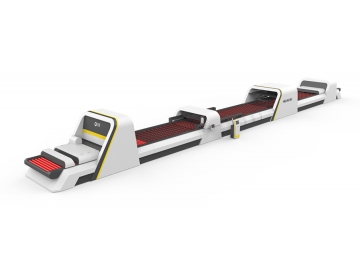

Automatic Laminating Machine (SADF Series Double Side Type)

Dual-use laminating machine for no-glue film and pre-glued film;

Applicable to either single side film laminating or double-sided film laminating.

Our latest SAFD-800B double-sided film laminating machine is developed conforming to the market demand. It can realize automatic paper feed, slitting, collection and temperature control. Our film laminator has touch screen operation and electrical elements centrally controlled by a programmable system.

Our double-sides film laminating machine features high degree of automation, high precision of coating, user-friendly configuration and easy operation. Obviously, our laminating machine for sale is indeed an excellent high performance coating equipment preferred by medium to large sized laminating companies.

Parameters of Double-Sided Film Laminating Machine| Model | |

| Maximum paper size | 800mm×1,040mm |

| Minimum paper size | 300mm×300mm |

| Printing speed | 0 m/min -50m/min(Single side ) 0 m/min - 40m/min(Double-sided) |

| Paper weight | 100 g/m2-500 g/m2 |

| Total power | 37kw |

| Dimension | 6,200mm×1,600mm×1,900mm |

Features

1. The pre-stack paper feeding system has oil-free vacuum pump to supply paper via air suction, which can realize continuous paper feeding without stopping the machine and improve the work efficiency;

2. Our double-sided film laminating machine's human-machine interface system features color touch screen and simple operation. You can just directly enter the paper size, superposition distance, machine speed, etc., and it will have fully automatic operation. The operator can observe the machine's working status from the touch screen at any time;

3.The automatic paper feed system of our film coating machine is equipped with photoelectric controlled protective device, which will make the feeding automatically stop when the paper is run out or overlapped;

4. The conveyor transports the paper via air suction. It is equipped with pre-register devices to not only ensure the paper is stacked stably and neatly, but also improve the accuracy of coating;

5. The upper heating roller uses hot oil circulation system and the bottom heating roller uses cast aluminum heater. The temperatures are separately controlled so as to ensure the accurate temperature of coating on each side;

6. Our double-sided film laminating machine's automatichydraulic system can provide stable big pressure to ensure the quality of laminating;

7. Both of the upper and bottom film laying devices use expansion axle and convenient roll, which can help to accurately position the film; it also has pneumatic clutch brake unit to realize winding and rewinding;

8. With the pneumatic cutting system, the operator can simply enter the paper size on the touch screen, and the paper will be automatically cut into required size;

9. The collecting unit of our film laminating machine hasvibration table and scroll. The cut paper will be collected and sorted by the vibration table; the film laminated paper does not need cutting will be rolled up by the scroll.