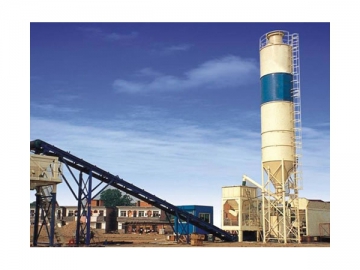

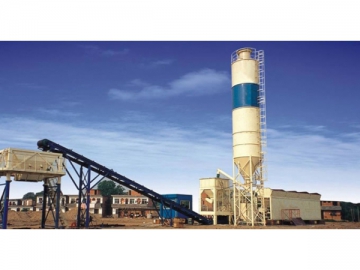

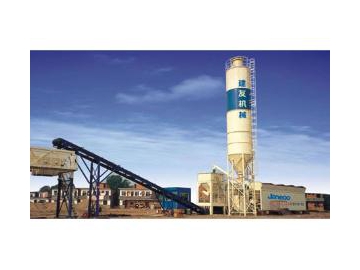

Stabilized Soil Mixing Plant

The stabilized soil mixing plant is mainly used in the construction of airports, ports and highways. It can continuously produce stabilized soil- which is the base material of any road. The main structure includes an aggregate batching, supplying and weighing system, powder supplying and weighing systems, a water supply system, a mixing device, a material storage device and control system.

1. The forced continuous mixer in our stabilized soil mixing plant comes with a non-scale board double horizontal shaft. We choose to use electric lubricant pumps and world-class German shaft-end seal designs. It is difficult for sand and dirt to enter the bearings. The end seal does not need frequent maintenance, and has a long service life. When it does need to be replaced, the process is simple.

2. Our advanced electronic frequency conversion speed control belt scale can easily be adjusted to control the speed rate of the stabilized soil mixing plant. It is accurate and precise. The frequency converter comes from famous international companies, ensuring the product is reliable.

3. The modular material silos of the stabilized soil batching plant are connected by hinge pins, which allows for easy installation, detachment, and transportation.

4. A small tilt angle belt conveyor is used for material collection and product transferring. Its structure is compact, allowing this belt conveyor to run smoothly with a low possibility of deviation. It also has a long service life.

5. The mixer in this plant has a large volume, high productivity rates, and a good mixing performance.

6. Our finished product storage system comes with pneumatic double door opening devices. The volume is large, and material discharge rates are fast.

7. In order to achieve better safety and stability, the main electric components of the stabilized soil mixing plant are all from famous international companies.

8. Our company provides over 40 models of stabilized soil mixing plants, and are available in three different structures: a modular container, mobile, and stationary.

9. Various kinds of material including cement and various types of stabilized soil can be mixed here.

10. Other features of the stabilized soil mixing plant include good craftsmanship, a compact structure, accurate measuring and excellent mixing performances.

| Model | ||||

| Theoretical productivity ( m3/h) | 300 | 500 | 600 | |

| Mixer | Power (kW) | 2×22 | 2×30 | 2×37 |

| Aggregate diameter (mm) | 50 | 50 | 50 | |

| Aggregate bins | Volume ( m3) | 9 | 9 | 9 |

| Belt conveyor capacity (kW) | 400 | 600 | 700 | |

| Scales capacity and accuracy | Aggregate (kg) | ±2% | ±2% | ±2% |

| Cement (kg) | 1% | 1% | 1% | |

| Water (kg) | -1%~ 2% | -1%~ 2% | -1%~ 2% | |

| Power (kW) | 92 | 123 | 147 | |

| Discharging height (m) | 3.6 | 3.6 | 3.6 | |

Note: All specifications of the stabilized soil mixing plant are subject to modification.

Modular container type weighing system

1. The number of material silos can be adjusted according to your needs.

2. Our stabilized soil mixing plants are easy to install, disassemble and transport.

3. We have adjusted the aggregate belt scale and mixed material conveyor in advance, making the installation of our stabilized soil equipment much easier.

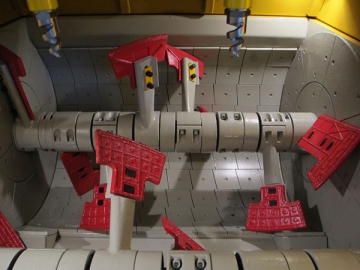

Efficient and reliable mixing system

1. In the stabilized soil mixing plant, the advanced forced double horizontal shaft continuous mixer comes with no scale board, so there is no need to ever replace it.

2. The discharge outlets on both sides and the bottom of the mixer make cleaning the plant fast and easy.

3. Our special, anti-wear alloy blades have a longer service life.

4. We have an extended mixing arm and have optimized the mixing blade structure of the stabilized soil mixing plant in order to make the material better and avoid material separation after mixing.

5. We chose to use electric lubricant seal pumps and world-class German shaft-end seal designs. The three stage sealing structure includes a labyrinth sealing, rubber sealing and a cemented carbide floating sealing. These all make it difficult for dirt and other impurities to enter the bearings. The end seal rarely needs maintenance and has a long service life. When it does need to be replaced, the process is quick and easy.

Automatic, accurate, and reliable cement supplying and weighing system

1. The cement silo of the stabilized soil mixing plant can be designed according to your needs. You can choose from a volume of 50 tons, 80 tons, 100 tons and more. You can also choose between a single or double silo structure, and various other combinations, making your order customizable.

2. We can also provide a total weight measuring device, an individual weight measuring device, and various other optional equipment, such as a sacked cement conveying system, a bucket elevator and more.

3. An enlarged material outlet is designed for the cement silo to make material discharge more efficient, and the measuring process more accurate. A set of arch breaking devices are also mounted so cement can be continuously and precisely measured, even after a long storage period or after getting damp.

4. The cement weighing device of the stabilized soil mixing plant comes with an overflow reamer scale and a measuring reamer scale. The automization degree is high and accurate measurements are desirable. The overflow reamer scale has a wide material inlet, so that cement can completely fill the scale, guaranteeing continuity and reliability. The outlet is a special overflow structure, so that material can come out continuously and stably, leasing to a highly accurate measurement reading. The measuring reamer scale is a suspended structure, so it is free from ambient impact.

5. The entire measuring control system of the stabilized soil mixing plant consist of a sensor, PLC, computer, and frequency converter. After an adequate commissioning, the measuring process can be done accurately and automatically.