Punch Pin

Material

SKH51, M2, 1.3343, HSS, SKD61, equivalent

Hardness

SKH51, M2, 1.3343 HRC 60-62

SKD61, HRC 58-62

Specifications

Standards: MISIMI / DIN / AISI etc.

Mounting Method: flange fixing

Service: OEM is available, and standard punch pins are in stock

Customization is available

Closest Tolerance: shaft: 0mm to -0.01 mm, head: 0mm to -0.05 mm

Diameter Arrange :According to customer demand

Polishing: can be close to Ra 0.4, the standard is R0.8

Our steel punch pin has tough and resilient shaft; its hardness has been greatly improved by our nitrogen treatment. Moreover, we are pleased to manufacture punch pins with other dimensions, lengths and materials according to your requirements.

More press die components can be produced according to DANLY / DME / HASCO / TOHATSU / FIBRO / AGATHON / STRACK / PEDROTTI / RAYMOND / FUTABA / SANKYO / PROGRESSIVE / RABOURDIN, etc.

Application

As also a professional hole punch manufacturer, we adopt the imported high quality steel, the newest CNC machining center and Swiss Archie's cutting mill machine line to the manufacturing and processing of our roll pin punch.

We are happy to customize your designs and logos. Our punch pin is suitable for different plastic bag making machines; it can punch such materials with 0.01mm single-layer as the plastic bag, paper, non-woven fabrics, PE, OPP, PO, PP, PVC, PPE, PPU, OPE Film, etc. Also, the punch pin can be easily replaced if it is worn.

Further Information

| Testing Machine | Digital height gauge, caliper, coordinate measuring machine, projection machine, roughness tester, hardness tester, etc. |

| QC | 1) Technicians do self-check in the production 2) Engineers do spot check in the production 3) QC personnel do inspection after the mass production finished 4) International salesmen with technical know-how do spot check before shipping |

| Main Markets | North America, South America, Eastern Europe, West Europe, North Europe, South Europe, South Asia |

Packing and Delivery

| Package | Coated with anticorrosive oil, packed in carton box; in bubble wrap, together with QA report. |

| Delivery | By Sea or By Air |

| Express | DHL, FedEx, UPS, TNT, EMS, etc. |

Main Products

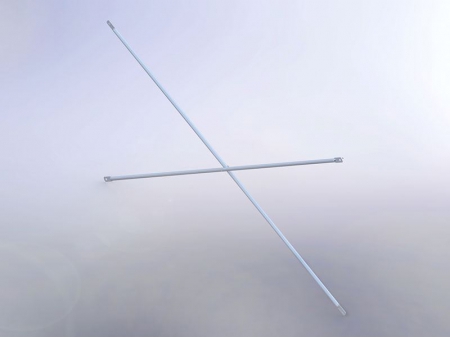

Guide Pillars, Guide Bushings, Guide Post Set, Ball Cages

Mold Ejector Pins, Ejector Sleeves, Oiless Bush, Bronze Wear Plate

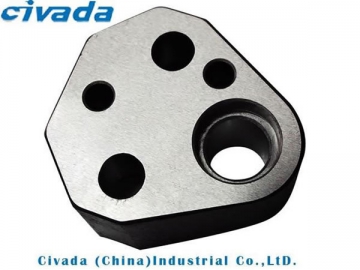

Punch Pin, Die Button, Ball-lock Punch, Punch Retainer.

We have the following punch products for sale:

Ball-lock Punch

Our ball-lock punch has regular style and nose large style; it features quick change and is suitable for light duty/heavy duty/extra heavy duty applications.

Shoulder (Headed) Style Punch

The shoulder/ headed style punch is manufactured with commercial standard and precision tolerance.

Dura Punch

With particularly designed thicker, larger and 10° angled diameter head, our dura punch can effectively avoid error when piercing heavy gauge and high strength materials.

Quill

The quill punch has straight and bevel style head.

Stock and Customization

Our ball-lock and shoulder type punches with all kinds of sizes are available in stock. We are happy to provide heat treatment and coating for custom punches and enable them to have enhanced performance applicable to piercing, piloting, forming or bending in different materials.

Surface Coating

TiN (Titanium Nitride) PVD (Physical vapor deposition) Coating

TiN is the most economical and commonly used PVD wear resistant coating and it has the following advantages:

a. Excellent wear resistance

b. Superb performance of lubrication

c. Thermal stability suitable for most cold work metalworking applications

d. High micro hardness up to 2,300 Vickers

Note: TiN is recommended to be used with lubricants; and it is not applicable to stainless steel, nickel or copper applications.

TiCN (Titanium Carbon Nitride) PVD Coating

TiCN can be widely applied to PVD coating on stainless steel, nickel and copper metals; and it has the following merits:

a. Higher hardness and lower coefficient of friction than that of TiN coating; thus, it has extremely high wear resistance

b. Improved performance of lubrication

c. Extremely high micro hardness up to 3,000 Vickers

Note: It is suitable for stainless steel, nickel or copper applications.

TiAIN (Titanium Aluminum Nitride) PVD Coating

Particularly suitable for application generating heat on surface, TiAN can convert the aluminum constituent to aluminum oxide, which provides an extra protection against shear stress and wear resistance on cutting edges. TiAN has the following features:

a. High thermal stability

b. Extremely high micro hardness up to 3400 Vickers