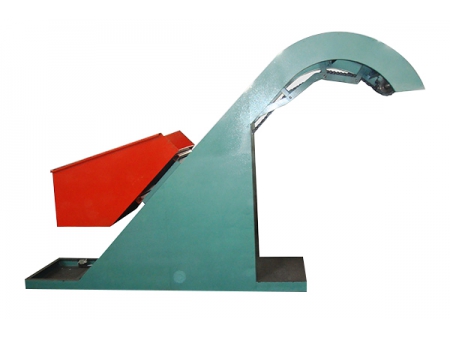

Bucket Elevator

Should you need a bucket elevator or vertical transportation solution, DEGAO is here to help.

Features of Bucket Elevator

1. Compact structure with a small cross-sectional area allows the bucket elevator to maintain a relatively small, space-saving footprint.

2. Head Section

The head pulley or head sprocket of the bucket elevator is encapsulated with resin to increase friction and reduces the slip risk. Therefore, a high power transfer efficiency can be assured.

Bend and incline sections are used to increase discharge height, allowing more time that can be taken to unload the material. The use of adjustable baffle plate and buffer chamber effectively reduces the amount of returning materials. High quality liners inside the head section are made of abrasion-resistant polymers.

3. Intermediate Section

A snap lock machine has been used to create weather-tight, reliable joints along the edges of the intermediate section. Balance pipes are used to equalize the pressure between two parts of the section.

The inspection door provides a large opening which allows inspectors to check the inside of the entire bucket elevator and replace the bucket. A pressure relief door is fitted to the section, eliminating the risk of explosion or overload.

4. Tail Section

Uniquely designed shaft seal of the bucket elevator prevents leakage of powder along the rotating shaft. Pillow block is mounted on a base independent of the motor assembly. Adjustable baffle plate contains two seals to prevent leakage.

5. Backstops are used to prevent discharge plug in the event of power outage.

6. Operational features include the speed detector and pulley runout alarm, which ensures safe operation.

7. Used for vertical transportation of powders, particulate matters and lumpy materials in animal feed factory, grain warehouse, food, chemical engineering, and building material industries. This material handling equipment is also commonly seen at sea ports and wharves where bulk materials need to be lifted.

Technical Specifications| Model No. (TDTG) | ||||||||

| Productivity (t/h) | Grains | 8 | 15 | 20 | 25 | 35 | 45 | 65 |

| Powders | 5 | 12 | 18 | 20 | 25 | 25 | 35 | |