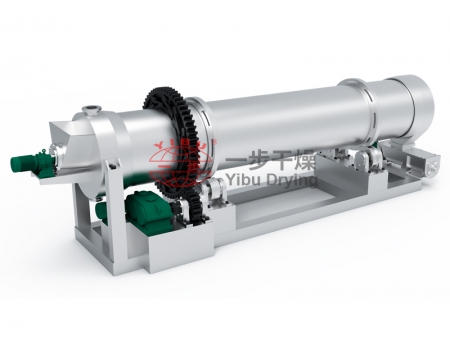

Drum Dryer

Benefits of Drum Dryer

I. Reliable Drum Drying Techniques

The use of triple pass drum drying technique for efficient and cost effective drying or dehydration of a wide range of materials is pioneered by the Germans. DEGAO triple pass drum dryer is made up of three cylinders that are concentric and mechanically interlocked to rotate at the same speed. Wood shavings enter the drum at one end, and first pass through the inner cylinder. This is called the first pass.

Under the action of flights which are installed inside the drum, the shavings are moved backward through the intermediate cylinder and then pass forward again through the outer cylinder. When the dry shavings are finally discharged, they actually have traveled a long distance three times the length of the drum. As a matter of fact, the drum dryer has benefits beyond saving space and efficient drying. Further advantages of using this material drying equipment are listed below.

1. Slow motion reduces the risk of severe wear, increases safety and reliability, and 热requires limited repair and maintenance.

2. Adjustable feeding speed, simple operation

3. Large production capacity, designed for continuous operation

4. A high of flexibility in operation allows the production capacity to be adjusted to market fluctuations in product demand while maintaining high product quality.

5. Explosion proof features are added to areas where spark or fire is likely to occur.

II. Efficient, Energy-Saving

Wood shavings inside both the intermediate and outer cylinders become scattered and widespread, which have a better chance of contact with hot air for heat exchange. Air temperature decreases from the inner cylinder to outer cylinder because less moisture would be contained in the wood shavings as they went through the three cylinders and thus less heat is needed. Unique concentric structure allows for better use of residual heat and reduces waste heat. The outer cylinder is coated with an insulation layer to prevent heat loss.

Heat transfer efficiency: 40%-50% improvements over traditional models

Volumetric heat transfer coefficient: double that of single-pass drum dryer

III. High Level of Automation

From feeding to discharging, each step is automatically executed inside the triple pass drum dryer. Precise control of exhaust air temperature, along with adjustable feeding speed, assures accurate moisture control, without product degradation. Exhaust air temperature is often controlled to a low level, so never worry about heat waste.

IV. Exceptional Finished Product Quality

Wood shavings retain much of their original color without being over-dried. Having been showered in the hot air stream, the wood shavings can have a moderate moisture content level below 15%.

| Model No. | Drying Capacity (kg/h) | Theoretical Evaporation Rate (kg/h) | Dimensions (m) (L×W×H) | Energy Consumption Kcal/h | Coal Consumption (Kg/h) |

| 1000 | 411 | 9X2.5X2.7 | 370, | 50 | |

| 2000 | 823 | 11X2.5X2.7 | 750, | 100 | |

| 3000 | 1235 | 15X2.5X2.7 | 1.12 million | 149 | |

| 4500 | 1852 | 12X2.8X3 | 1.50 million | 200 | |

| 5500 | 2264 | 16X2.8X3 | 1.80 million | 240 | |

| 6500 | 2676 | 18X3X4 | 2.52 million | 340 | |

| 7500 | 3088 | 22X3X4 | 3 million | 400 |

Please note that the above data is calculated under the assumption that the initial water content in wood shavings is 50% while the final water content after drying is 15%. All data need to be reworked if the water content value is outside this range.