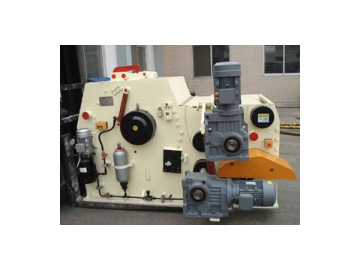

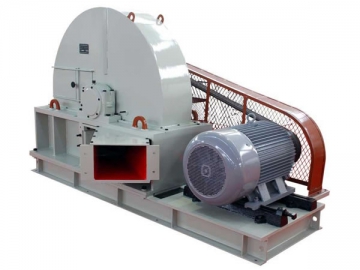

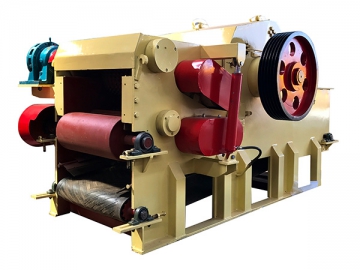

Drum Chipper

Wood chips make good quality biomass fuels. DEGAO provides an easy, powerful way of chipping up your woody biomass by offering this robust, uniquely designed drum chipper. DEGAO wood chipper can handle a variety of woody materials, including the small-diameter wood logs, planks, tops, branches, slabs, strips, limbs, or other wastes left over by forestry operations or wood production. Non-wood products including sugarcanes, reed, and bamboos also can be cut up by our tree chipper.

Below are only a few of many applications where our drum chipper can be used.

1. Chipboard factory

2. Medium to high-density fiberboard factory

3. Crop stalk factory

4. Biomass power plant

5. Wood chip plant

Common traits found this series of wood chipper include advanced structure, high chipping quality, compatibility with a variety of woody materials, and easy repair and operation.

Drum Chipper Structure Explained

DEGAO wood chipper is comprised of the main bodywork, roller cutter, upper feed roller, lower feed roller, belt conveyor, and hydraulic system. The main bodywork is made of high-strength steel sheets welded together, serving as the foundation for the entire wood chipper. On the roller cutter, 2 or 3 or 4 fly cutters are bolted to the roller together with pressure blocks.

According to the thickness of materials to be fed into the woodchipper, the upper feed roller can be hydraulically controlled to move up and down to adjust the gap between the two rollers. Qualified wood chips fall through the screen and are discharged from the bottom of wood cutting machine while oversize wood scraps will be sent back for rework.

The hydraulic system consists of the oil pump, oil cylinder and the hydraulic oil circuit. The outer cover of the wood chipper can be hydraulically opened to allow for knife replacement. In times of machine repair, the upper feed roll is hydraulically raised to allow the adjustment of the gap between the upper cutter and bottom knife as well as facilitate the installation and removal of comb plate.

Technical Specifications of Disc Chipper| Model No. | Number of Fly Cutters | Inlet Size (mm) | Maximum Feed Diameter (mm) | Size of Wood Chips (mm) | Power (kw) | Production Capacity (t/h) | Dimensions (mm) | Weight (kg) |

| 2 | 400×170 | 150 | 25-35 | 45 7.4 | 5-8 | 1800×1800× 1150 | 3100 | |

| 2 | 400×170 | 150 | 25-35 | 45 8.9 | 5-8 | 2600×1800× 1150 | 3380 | |

| 2 | 540×220 | 200 | 25-35 | 55 9.2 | 10-15 | 2000×2000× 1250 | 4420 | |

| 2 | 540×220 | 200 | 25-35 | 55 11 | 10-15 | 3100×2000× 1500 | 4680 | |

| 2 | 680×270 | 250 | 30-40 | 110 12.5 | 18-25 | 2400×2180× 1500 | 7120 | |

| 2 | 680×270 | 250 | 30-40 | 110 14.7 | 18-25 | 3500×2180× 1800 | 8320 | |

| 4 | 700×360 | 300 | 30-40 | 220 17 | 30-40 | 3680×2450× 2050 | 11850 | |

| 4 | 960×460 | 420 | 30-40 | 220 20 | 35-50 | 4200×2900× 2330 | 16280 | |

| 2×2 | 1200×400 | 300 | 30-40 | 350 24 | 60-80 | 7700×2960× 2200 | 19600 |