CNC Angle Punching Line

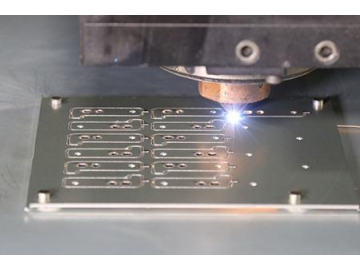

Our CNC angle punching line for angle steels is a special CNC machining system used for punching angle steels in the electric, communication and tower industries. Its electrical elements and pneumatic components are all of stable quality.

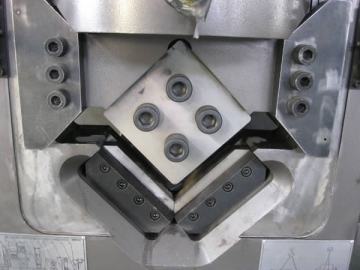

The punching unit has an infeed channel on the right, and an outfeed channel on the left. The punching unit is equipped with an 80t open power press with a fixed bed. Our CNC punching machine has two sets of punching dyes used for punching holes with different diameters, and the programming on the principal computer will decide the diameter of the holes that need to be punched.

Features

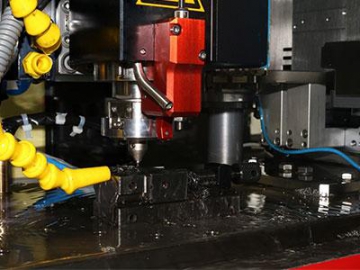

1. By using a ball screw, our CNC angle punching line’s servo motor can allow the angle steel to move horizontally and change the stadia. The air cylinder can also tightly press the angle steel on the plate to provide reliable guarantees for the stadia.

2. There are guide rails and racks on the infeed channel. Driven by the servo motor, the CNC trolley can move on the infeed channel and guarantee accurate positioning of punching holes on the angle steel.

3. This automatic angle steel machining equipment uses CNC technology, and its feeding system is controlled by a servo motor. Due to that, it’s got great efficiency and can generate work pieces with stable precision.

4. The programming is simple, and the operator can use data generated from the sample software.

5. Our CNC angle punching line for angle steel supports both Chinese and English, making it easy to operate. It can also display the work piece’s figures.

6. The operator only has to enter work piece information such as bore diameter, dimensions, stadia and quantity when programming.

7. Our CNC punching machine has the capability to self-diagnose faults.

8. There are two oblique unloading devices to prevent the work piece from being dislodged during the punching process.

Parameters of CNC Angle Punching Line| Model | |

| Functions | Punching |

| Processing range (mm) | From 40×40×3 to 160×160×12 |

| Max. punching diameter (mm) | Φ26 |

| Number of punching head | 2 |

| Stadia of punching holes (mm) | From 20 to 110 (Stepless) |

| Min. distance between hole and plate's edge(mm) | 25 |

| Punching force (kn) | 800 |

| Number of CNC axes | 2 |

| Positioning speed of servo motor(m/min) | 20 |

| Programming mode | Keyboard input, RS232 interface, floppy disk and USB interface |

| Processing precision | In accordance with GB2694 |

| Dimension (L×W×H) (mm) | 18,900×2,300×2,600 |

| Weight (kg) | 8,250 |