Chrome Plated Rod

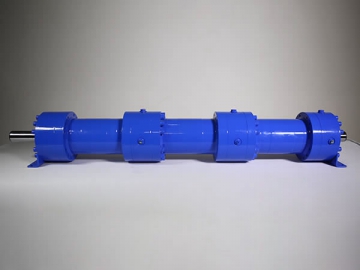

We offer several models of precision-made chrome plated rods, such as the hard chrome plated rod, ID unhoned OD plated hollow rod and ID honed OD plated hollow rod. Each of these three models are widely used in hydraulic cylinders, air cylinders, vibrations absorbers and pistons for various industrial machinery, textile equipment, slideways of printing machines, die casting machines, injection molding machines (which use them as guide rods and ejector rods), and 4-column hydraulic presses (which use them as guide rods). These rods also serve as guide shafts for office machines, including fax machines, copying machine, high-speed mimeographs and printers.

This hard chrome plated rod, with an external diameter ranging from φ10mm to φ800mm, is mainly designed for hydraulic cylinders (piston rods), air cylinders (piston rods), plastic manufacturing equipment (guide rods), hydraulic machinery (guide rods), packaging machines (rollers), printing machines (rollers), textile machinery (axle centers) and transport machinery (axle centers).

The outer diameter tolerance of this piston rod reaches from F7 to F8, its surface finish is RA0.1 to Ra0.4, hardness of chrome plating above HV800, thickness of plating 0.02 to 0.05mm, and hardness of quenched rod HB220 to HB227. Made of such quality steels as CK45, 40CrMo, 35CrMo, 42CrMo, 1Cr13, and 2Cr13, our plated rods have undergone cutting, quenching/heat treatment, straightening, turning, coarse grinding of the outer surface, straightening, accurate grinding, finishing, chrome plating (surface treatment), lathing, finishing and packaging.

This ID unhoned OD plated hollow rod is used in hydraulic cylinders (piston rods), air cylinders (piston rods), plastic manufacturing equipment (guide rods), hydraulic machinery (guide rods), packaging machines (rollers), printing machines (rollers), textile machinery (axle centers) and transport machinery (axle centers). With the outer diameters ranging from φ25mm to φ800mm and a wall thickness from 3mm to 100mm, this chrome plated hollow rod has a smaller outer diameter tolerance (f7 - f8), good finishing (Ra0.1 to 0.4) and high hardness of chrome plating (above 800). The plating thickness of this rod ranges from 0.02mm to 0.05mm (which can also be customized).The hardness of the quenched rod ranges from HB220 to HB267.

At the same time, its bore helps reduce weight or be used in oil injections. Made from quality steel like CK45, 40Cr, 35CrMo, 42CrMo, 1Cr13, 2Cr13, each rod undergoes cold drawing, cutting, quenching/heat treatment, straightening, turning, coarse grinding of the outer surface, straightening, accurate grinding, finishing, chrome plating (surface treatment), lathing, finishing and packaging.

This ID honed OD plated hollow rod is used to manufacture multi-stage hydraulic cylinders. Made of quality steel such as CK45 and 40Cr, this cylinder rod has undergone high precision honed tubing, cutting, straightening, turning (taking the bore as benchmark), coarse grinding of the outer surface, straightening, accurate grinding, finishing, chrome plating (surface treatment), lathing, finishing and packaging.

Its bore diameter tolerance is from H8 to H9, fine finishing from RA0.2 to Ra0.4, plating harness above HV800, plating thickness from 0.02 to 0.05 and the hardness of quenched rod from H220 to HB267.

Technical Specifications of Chrome Plated Rod| Model | | | | |

| Length | 800-2000mm | 1000-3000mm | 1000-3500mm | 1000-5800mm |

| Finish | Ra0.4-0.1(△8-△10) | |||

| Surface Hardness | Above HRC60 | Straightness | 0.12/1000mm | |

| Roundness Tolerance | Grade 9(GB1184) | Plating Thickness | 0.02-0.03mm | |

| Length Tolerance | Grade IT7 (GB1800) | Hardness of quenched rod | HB220-260 | |

| Processes | high-and-mid frequency quenching, high temperature tampering, chrome/nickel/phosphor plating | |||