Honing Machine

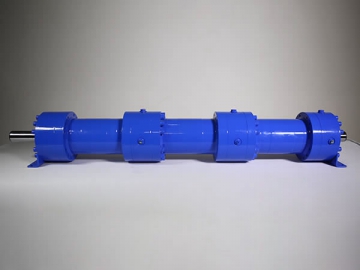

A honing machine finishes the surface of metal products, especially for cylinders. Based on our strong R&D and manufacturing capacity and years’ rich experience, we have provided a vertical honing machine with our customers.

This reliable metalworking equipmentis well designed and efficient, with an operating precision of IT5~IT6 and good finishing (Ra0.8 to 0.1μm). Because of its semi-automatic control, it is easy to operate and has a long service life. The vertical honing machine is designed to avoid or smooth over any bore errors. Due to its reliable performance, this honing machine is increasingly being used in a number of applications, especially as we continue to incorporate new designs to improve this machine’s efficiency and labor intensity.

Features of Honing Machine

This industrial honing machine is highly reliable and efficient with the following features:

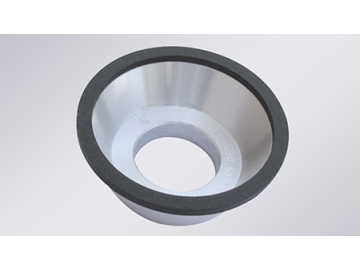

1) The efficiency of this honing machine is six times that of the internal grinding machine and other bore finishing equipment. Additionally, it requires only half the time for debugging as that of other counterparts;

2. With this advanced honing machine, customers can better control their manufacturing cycle, ensuring that each work piece is completed consistently and in the same amount of time. Automatic adjustment of the feeding speed increases the honing performance, efficiency and quality;

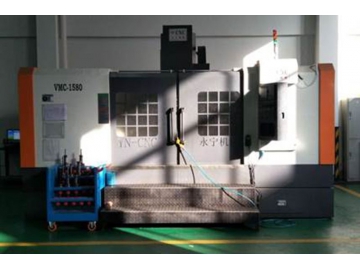

3. The chassis of this honing equipment is made of strengthened steel and is very stable. As the chassis is separate from the moving parts of the machine, it won’t vibrate or rock. The programmable stroke control and processing cycle control not only optimize the entire manufacturing cycle but also ensure high precision and quality;

4. A wide pressure adjustment scale ranges from 1MPa to 16MPa. The high feed pressure could eliminate working allowance and lessen the processing cycle.

Application of Honing Machine

This honing machine is excellent at processing bores of diameters ranging from ф30~ф500mm and deep bores of strokes longer than 4 meters, effectively enhancing the technical precision of the finished products. Because of this, the honing machine is widely used in the cast iron industry, quenched steel making and production of metal parts in which oil may clog. This honing machine has been widely used to process hydraulic cylinders, cold drawing machinery, molds, injection mold machinery, vehicles, mining machinery, lathes and more.

Basic Specifications of Horizontal Honing Machine(HMY Series)

Maximum Outer Diameter of Tubes: Φ160 - 400mm;

Maximum Length of Tubes: 2 – 14m.

| Model | | | | |

| Maximum Outer Diameter | Φ 245/ Φ 480 Φ245 /Φ480 | Φ 245/ Φ 480 Φ245 /Φ480 | Φ 245/ Φ 480 Φ245 /Φ480 | Φ 245/ Φ 480 Φ245 /Φ480 |

| Maximum Length (m) | 2,2.5,3,3.5,4,5 2, 2.5, 3, 3.5, 4,5 | 2,2.5,3,3.5,4,5 2, 2.5, 3, 3.5, 4,5 | 6,7,8 6, 7, 8 | 9,10,12,14 9, 10, 12, 14 |

| Main Gear Box | Lathe | Lathe | Lathe | Lathe |

| Transmission Type | Hydraulic | Hydraulic | Chain Transmission | Chain Transmission |

| Honing Head | Manual/Automatic Hydraulic | |||

| Structure Type | Bed Type/Rail Type | |||

| Cooling Type | Recirculation Cooling Mode | |||

| Complete Machine | 6/86/8 | 9/15.59/15.5 | 88 | 17 17 |

| The above data are only for reference. Technical specifications of our productscomply with the contracts, according to each customer’s requirements. | ||||