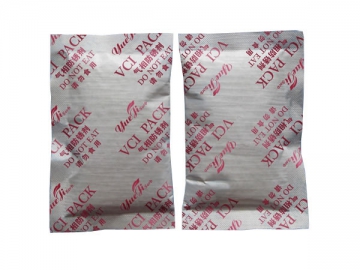

Vapor Corrosion Inhibitor

The vapor corrosion inhibitor (VCI), also called a volatile corrosion inhibitor or vapor phase corrosion inhibitor is used to protect ferrous metals, particularly aluminum, against corrosion when it is impractical to apply surface treatments. This rust inhibitor has excellent volatility and diffusivity as well as great absorption performance.

After being volatilized, the VCI will be absorbed onto the metal surface and form a protective layer which can effectively prevent rust. The VCI works great for protecting recessed and hard to reach areas such as deep holes, elongated tubing, gaps, etc.

Product Features

1. For hard-to-reach metal surfaces, the vapor corrosion inhibitor more effectively protects against rust than other antirust agents due to its volatility. Especially, for metal pieces with hidden internal surfaces or intricate shapes, our vapor corrosion inhibitor is effective, safe, and afforable.

2. The VCI can be used alone or in conjunction with other vapor phase corrosion inhibitors to achieve oil free packaging or eco-friendly, affordable packaging. The ferrous metal product can be directly delivered to customers without any treatment, thus saving time and cost.

3. The VCI protective layer on the surface of the metal surface doesn't need to be removed before processing the metal piece. However, if required, the VCI layer can be easily removed by an air or water hose.

4. When the sealed packaging is opened temporarily and then resealed, the VCI protective layer may be damaged, but our VCI molecules can automatically repair it.

5. The VCI offers continuous protection for 12 months. The effective protective area is 100g/m3.

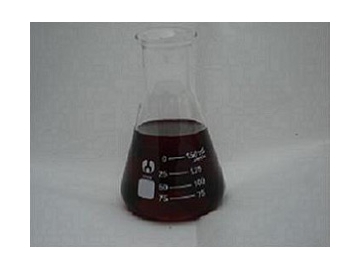

Physical and Chemical Characteristics

Appearance: white or light yellow solid powder with slight odor

PH value: 7.0~8.0 (10%)

Water solubility at normal temperature: 75g

How to Use

1. Put the vapor corrosion inhibitor packet in the space to be protected and keep the space sealed. The effective operating distance is 30cm.

2. The VCI can protect the product for up to 12 months. Under normal circumstances, the amount of VCI to use in a sealed space is 100g/m3. In severe environments, the amount should be increased.

3. The VCI protective layer on the surface of the metal surface doesn't need to be removed before processing the metal piece. However, if required, the VCI layer can be easily removed by an air or water hose.

To Keep In Mind

1. The surface of the metal piece should be free from rust, oil stains, sweat, dust, water, or any other moisture before applying the VCI.

2. Make sure the amount of VCI packets being used is sufficient.

3. Desiccant packets can be used with the VCI in packaging metal products.

4. When the VCI is used for large products, the packets should be uniformly placed in the packaging with the distance to the metal surface less than 30cm. When used for tubular products, it should be evenly distributed throughout the inner part.

5. When using a VCI, holes and pipes must be completely blocked. Large products should be sealed.

6. The VCI reacts differently to oil paint and rubber parts, so pay attention to the non-metal parts when using VCI.

7. If the package is opened temporarily, reseal it as quickly as possible.

Package and Storage

1. VCIs can be packaged 5kg/bag, 10kg/bag or 20kg/bag. After packaging in water-proof bags, they should be put in iron drums or high strength cartons.

2. The transportation vehicles for VCIs should be clean and covered in case of rain or snow. Gentle handling will avoid damaging the package.

3. The storage area should be cool, dry, and clean to avoid damaging the packaged VCIs. They should not be stored directly on ground or with chemicals and it should not be exposed to the sun. The distance to any heat source shouldn't be less than 1m; the distance to ground at least 0.1m.

4. The VCI should be used as soon as it taken out of the package. If not used up, it should be resealed again.