Roll-Fed Patch Handle Paper Bag Machine

Model: ZD-FJ11-P/13-P/18-P

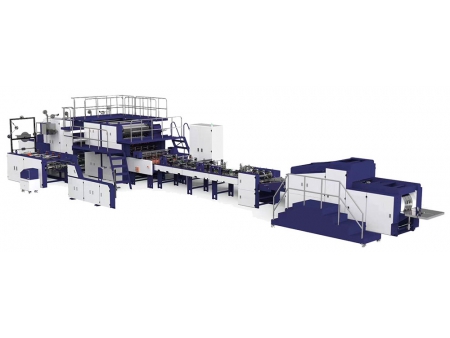

Fangbang is a dedicated Chinese paper bag equipment manufacturer. One of Fangbang's top products is the ZD-FJ11-P/13-P/18-P roll-fed paper bag making machine, designed specially for producing patch handle carrier bags.

This paper bag equipment takes paper rolls as raw material and produce in volumes quickly of patch handle bags. The high level of automation means various complicated production processes can be done easily on the paper bag making machine at a press of a button, operations including paper roll unwinding, patch placement, body panel forming, punching holes (in the patch reinforced handle), cutting, and adding the square bottom.

Technical Specifications

| Model | | |

| Paper Roll Width | 370~890mm | 450~970mm |

| Max. Paper Roll Diameter | ф1200mm | ф1200mm |

| Paper Reel Core Diameter | ф76mm (3’’) | ф76mm (3’’) |

| Paper Thickness | 50~150g/m2 | 55~160g/m2 |

| Tube Length | 270~530mm | 270~530mm |

| Bag Body Width | 110~280mm | 150~320mm |

| Bag Bottom Size | 60~150mm | 60~150mm |

| Patch Length | 120~160mm | 120~160mm |

| Patch Width | 75~138.75mm | 75~138.75mm |

| Film Patch Thickness | 0.1~0.3mm | 0.1~0.3mm |

| Paper Patch Thickness | 80~160gsm | 80~160gsm |

| Die-cut Window Length | 30mm (It can be customized) | 30mm (It can be customized) |

| Die-cut Window Width | 80mm (It can be customized) | 80mm (It can be customized) |

| Max. Production Speed | 160bags/min (240bags/min w/o handles) | 160bags/min (220bags/min w/o handles) |

| Total Power | 33kw | 33kw |

| Total Weight | Approx. 10000kg | Approx. 10500kg |

| Overall Dimension | L12000mm×W3300mm×H1900mm | L12000mm×W3450mm×H1900mm |

| Model | |

| Paper Roll Width | 660mm~1230mm |

| Max. Paper Roll Diameter | ф1200mm |

| Paper Reel Core Diameter | ф76mm (3’’) |

| Paper Thickness | 80~170g/m2 |

| Tube Length | 270~530mm |

| Bag Body Width | 260~450mm |

| Bag Bottom Size | 60~150mm(85~180mm) |

| Patch Length | 120~160mm |

| Patch Width | 75~138.75mm |

| Film Patch Thickness | 0.1~0.3mm |

| Paper Patch Thickness | 80~160gsm |

| Die-cut Window Length | 30mm (It can be customized) |

| Die-cut Window Width | 80mm (It can be customized) |

| Max. Production Speed | 120bags/min (180bags/min w/o handles) |

| Total Power | 33kw |

| Total Weight | Approx. 12000kg |

| Overall Dimension | L12000mm×W3500mm×H1900mm |

During the cutting process, a photo eye is used to monitor the operation of the paper bag making machine and correct bag length errors if there is any, thereby ensuring the cutting precision. Advanced Siemens PLC system keeps the entire production in check. Specially designed bag gathering platform collects finished bags and add up the total number. This feature makes it easier for packers to pack the bags into bales, without the need to manually count the number of them. With a high speed at 240 bags per minute, the square bottom bag machine works very well with a number of bag sizes and is most suited for batch production operations in food and apparel packaging industries.

Sample

Featured in the follow pictures are patch handle paper bags made by our ZD-FJ11-P/13-P/18-P bag making machine.

Features

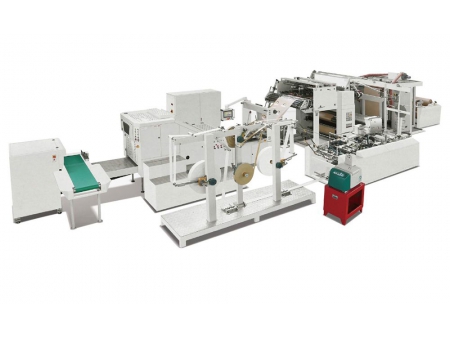

Just like the ZD-FJ11C/13C/18B machine, model ZD-FJ11-P/13-P/18-P paper bag production line works as fast in producing quality square-bottom paper bags without handles, though the latter is primarily designed to produce patch handle bags.

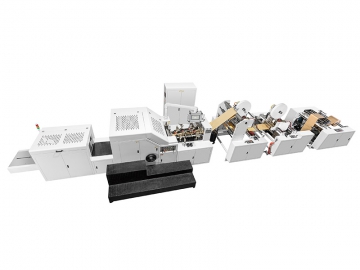

Close-up Views