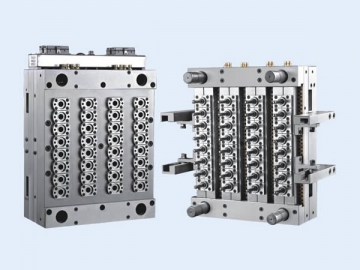

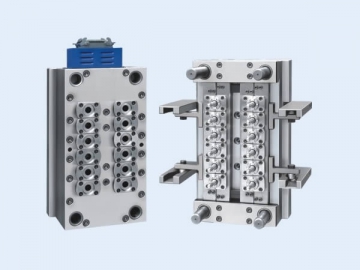

Preform Mould

- 12-Cavity Air Operated Needle Valve Type Hot Runner Preform

- 24-Cavity Air Operated Needle Valve Type Hot Runner Preform Mould

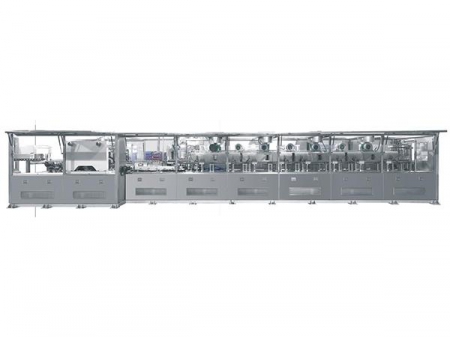

LONGHONG Machinery is a Chinese professional designer, manufacturer and supplier of beverage machines. We offer not only complete set of beverage production lines including blow molding machine, water treatment equipment, liquid filling machine and bottle labeling machine, but also preform moulds, blow moulds, bottle cap molds and other accessories.

With years of experience, we have designed and made two types of preform moulds, i.e. 12 cavity air operated needle valve hot runner preform mould and 24 cavity air operated needle valve hot runner preform mould. These injection moulds applies computer simulation of tensile strength test, ensuring high finished product rage. In addition, this PET preform moulds boast strong compatibility with our blow molding machines. We accept custom order of preform moulds for other brand blow molding machines.

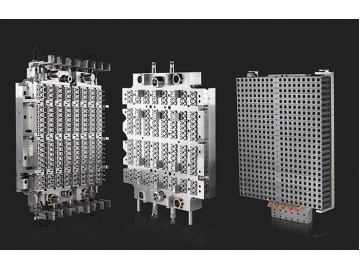

Features of Preform Mould

1. The blow molding machine accessory comes in common structure and twin cone auto clamping structure.

2. The cavity number of our PET preform moulds can reach 48 per mould.

3. It adopts world advanced double taper location technology. Each cavity can clamp automatically and independently. The concentricity is 0.08mm or less.

4. Mould cavity and core are made from Swedish S-136 or German 2083 corrosion resistant plastic mould steel, which ensures a high hardness up to HRC50 and a long lifetime.

5. Screw thread is made of imported nitriding steel according to international standard. Consequently, its hardness reaches HRC55, ensuring long service time.

6. Our preform mould features advanced hot runner design. The nozzles come with single point temperature control, hence ensuring uniform heating temperature and improving the quality of PET bottles.

7. Cut free pouring gate allows fully automatic production and reduce labors.

8. The lifespan of our preform moulds is more than 2 million molding times.